Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 674

Skip and Gauge Probing Cycles

Chapter 27

27-6

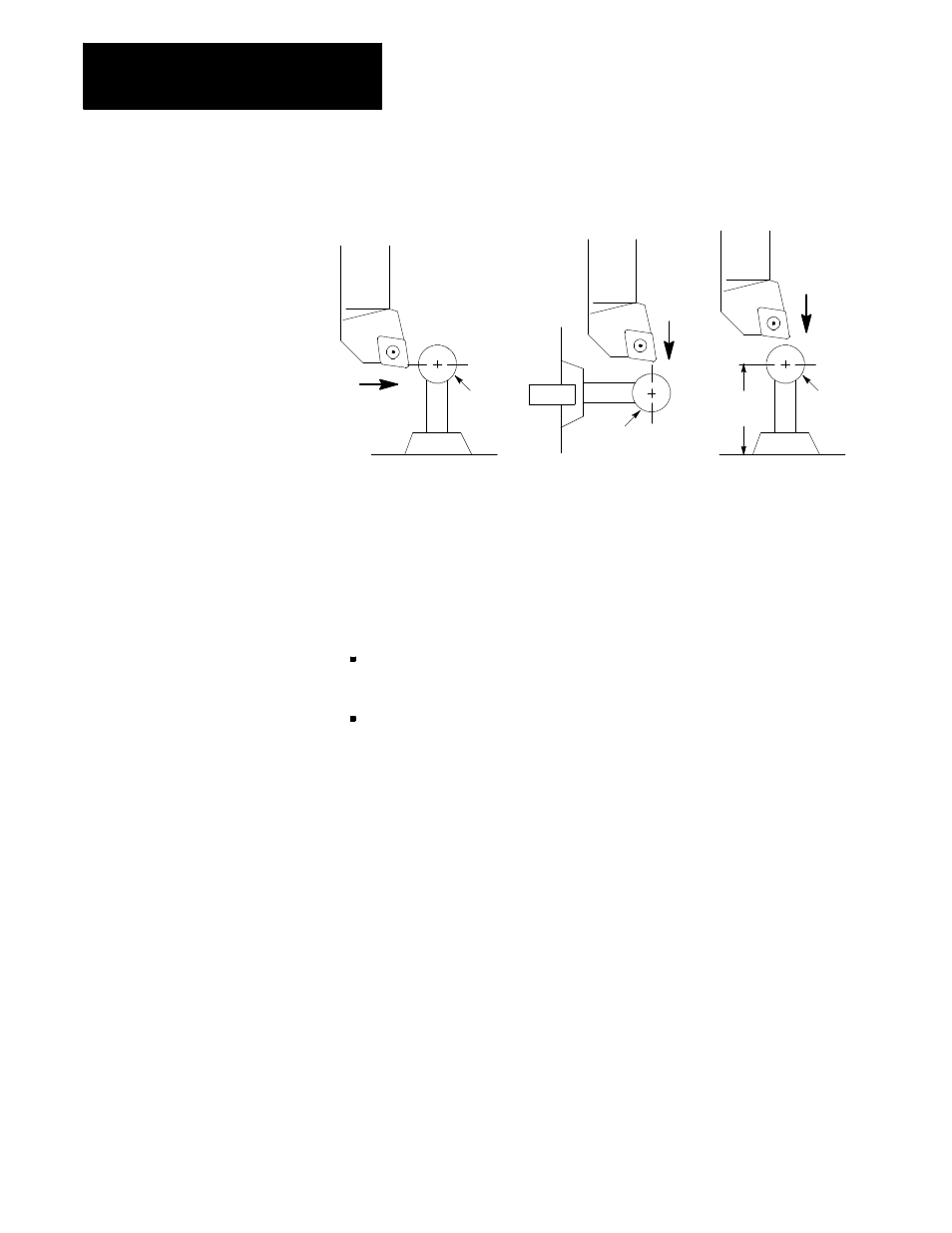

Figure 27.1

Typical Tool Gauging Configurations

Probe

Probe

radius

Tool

Probe

Probe

radius

Tool

Probe

Probe

radius

Probe

length

Tool

Case 1

Case 2

Case 3

+ Z

--X

--X

Figure 27.1 illustrates 3 typical tool gauging configurations. All 3 cases

assume that the probe is at a known, fixed point on the machine.

In Case 1, the Z axis tool offset length is being gauged, while in Case 2,

the X axis tool offset length is being gauged. In both cases:

only the probe tip radius is significant to the control in calculating the

offset adjustment

the reference position is the center of the probe ball

In Case 3, the X axis tool offset length is being gauged; and both the probe

radius and the probe length are significant to the control’s offset

adjustment calculations. In this case, the reference position is the bottom

of the probe.

Important: We do not recommend the tool gauging configuration Case 3

depicted in Figure 27.1 due to the risk of probe damage.

END OF CHAPTER

- 20P PowerFlex DC Drive - Frame D Bimetal Thermostat (10 pages)

- 1336S_F_T_E_R F Frame Snubber Resistor Repl. (6 pages)

- 22-COMM PowerFlex 4-Class DSI (Drive Serial Interface) Network Communication Adapter (4 pages)

- 8-545 Plug In Solid State Relay (2 pages)

- 20-HIM-B1 PowerFlex 7-Class HIM Bezel (DPI) (4 pages)

- 100 Contactors with DC Coil (1 page)

- 100 Contactors with DC Coil (2 pages)

- 20P PowerFlex DC Drive - Frame D Switching Power Supply Circuit Board (6 pages)

- 140G-MTFx_MTHx_MTIx_MTKx Trip Unit Installation-140G-M (6 pages)

- 45BRD Analog Laser Sensor (4 pages)

- 20D Multi-Device Interface Option Board for PowerFlex 700S Drives (20 pages)

- 56RF RFID 18 mm Cylindrical Transceiver (2 pages)

- 42KC Miniature Rectangular: 5V DC Version (2 pages)

- 20P PowerFlex DC Drive - Frame A Switching Power Supply Circuit Board (16 pages)

- 21P-MISC-A-TP-2 Transition Tube Kit #C19-6/7 For PowerFlex 755 w/OEM Liquid Cooling Fr 6/7 Drive (2 pages)

- 42BT Background Suppression Sensor (3 pages)

- 42CB High Speed 18mm Cylindrical (4 pages)

- 140EX-JE2_JE3 Molded Case Circuit Breaker (4 pages)

- 140G-K-EAM1A Early Make Aux Contact for Rotary Handle Oper Mech-140G-K (1 page)

- 140G-K-EAM1A Early Make Aux Contact for Rotary Handle Oper Mech-140G-K (3 pages)

- 20-HIM-A6 PowerFlex (Human Interface Module) (74 pages)

- 42CF General Purpose 12mm Cylindrical (4 pages)

- 20D PowerFlex 700S Phase II Drive Frames 1...6 (80 pages)

- 140EX-HE1_HE2 Molded Case Circuit Breaker (6 pages)

- 140EX-HE1_HE2 Molded Case Circuit Breaker (4 pages)

- 20B PowerFlex 700 Custom Firmware - Pump Off (12 pages)

- 20-WIM-N4S DPI Wireless Interface Module (92 pages)

- 140U H-Frame Circuit Breaker Fixed and Adjustable Thermal Trip (7 pages)

- 140U H-Frame Circuit Breaker Fixed and Adjustable Thermal Trip (2 pages)

- 60-2619, 42JS Swivel/Tilt Mounting Bracket (1 page)

- 22A PowerFlex 4/40/400 Flange Mount (4 pages)

- 45MLA Controller Installation Instructions (16 pages)

- 20P PowerFlex DC Drive - Cooling Fan for Frame A Drives Above 73A at 230V 460V AC (6 pages)

- 42JS Series 7000 to 42JS VisiSight Replacement Kit (2 pages)

- 22A PowerFlex 4-Class HIM Bezel (DSI) (4 pages)

- 42CS Stainless Steel Photoelectric Sensors (4 pages)

- 20L-LL PowerFlex 700L Liquid-to-Liquid Heat Exchanger (40 pages)

- 20P PowerFlex DC Drive - Frame B SCR Modules (20 pages)

- 22B PowerFlex 40 Quick Start FRN 5.xx - 6.xx (161 pages)

- 22B PowerFlex 40 Quick Start FRN 5.xx - 6.xx (22 pages)

- 22F PowerFlex 4M Input RFI Filters (2 pages)

- 45LFM Capacitive Label Sensor (4 pages)

- 140G-Rx Installation Instruction-140G-R (2 pages)

- 140G-Rx Installation Instruction-140G-R (29 pages)

- 22C PowerFlex 400 AC Drive Quick Start - FRN 1-4.xx (28 pages)