1 shared spindle configurations – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 753

Chapter 30

Using a 9/Series Dual--Processing System

30-13

Shared spindle configurations are for those dual-processing systems that

have one spindle that must be controlled by both processes. See

Figure 30.4. As a general rule for this type of machine, spindle control is

given to the process currently requesting spindle control.

WARNING: It is the programmer’s responsibility to watch for

conflicting overlap of spindle control between the two

processes. For example, one process should not request

clockwise spindle rotation while the other process requires

counterclockwise rotation. Prevention of overlapping spindle

control can be accomplished through synchronization M-codes.

See page 30-7.

Simple Spindle Speed and Direction

The process that requests a change in spindle speed or direction gets

control of the shared spindle. This can cause problems when both

processes are performing operations that require control over the spindle.

For example, consider the following program segments.

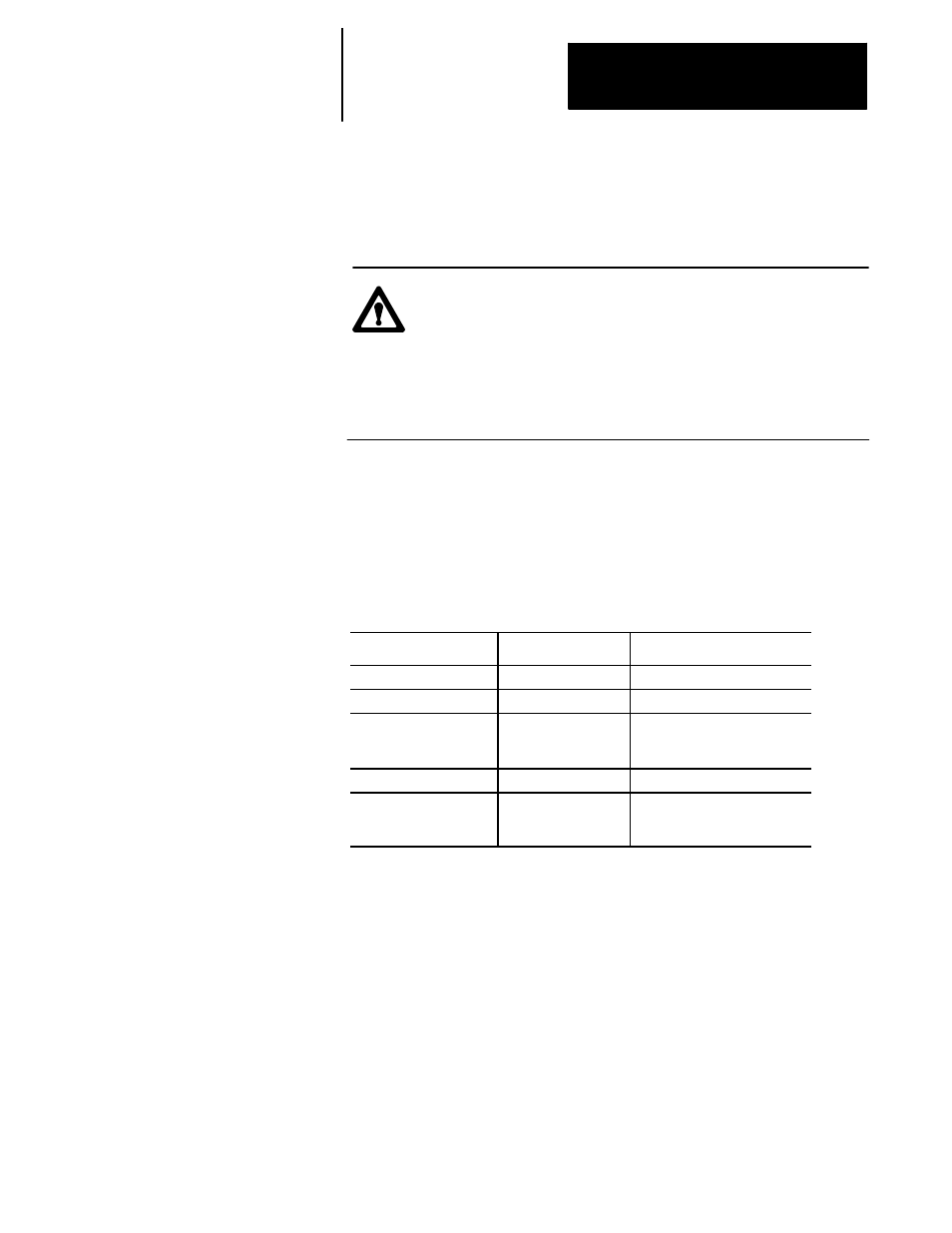

Process 1

Process 2

Shared Spindle Operation

N51 G97 S200 M04;

200 RPM, counterclockwise

N21 G97 S500 M03;

500 RPM, clockwise

N52 G01 X10 Z5;

500 RPM, clockwise

(cutting with process 2 direction

and RPM)

N22 G01 X12 Z--1

500 RPM, clockwise

N53 X12 Z3 S275;

275 RPM, counterclockwise

(cutting with process 1 direction

and RPM)

30.4.1

Shared Spindle

Configurations