G86.1): boring cycle, tool shift – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 654

Drilling Cycles

Chapter 26

26-28

In the G86 drilling cycle, the control moves the axis in this manner:

1.

The tool rapids to the initial point level above the hole location.

2.

The cutting tool then rapids to the R point level, slows to the

programmed cutting feedrate and begins the boring operation.

3.

The cutting tool bores at the programmed feedrate until it reaches the

depth of the hole as programmed with the Z-word.

4.

If the user has entered a value for the P parameter, the cutting tool

dwells after it reaches the bottom of the hole.

5.

The spindle or live tool stops rotating.

6.

The boring tool is then retracted at a rapid feedrate to the initial point

level, as determined by G98. Spindle or live tool rotation continues

forward.

When the single block function is active, the control stops axis motion

after steps 1, 2 and 6.

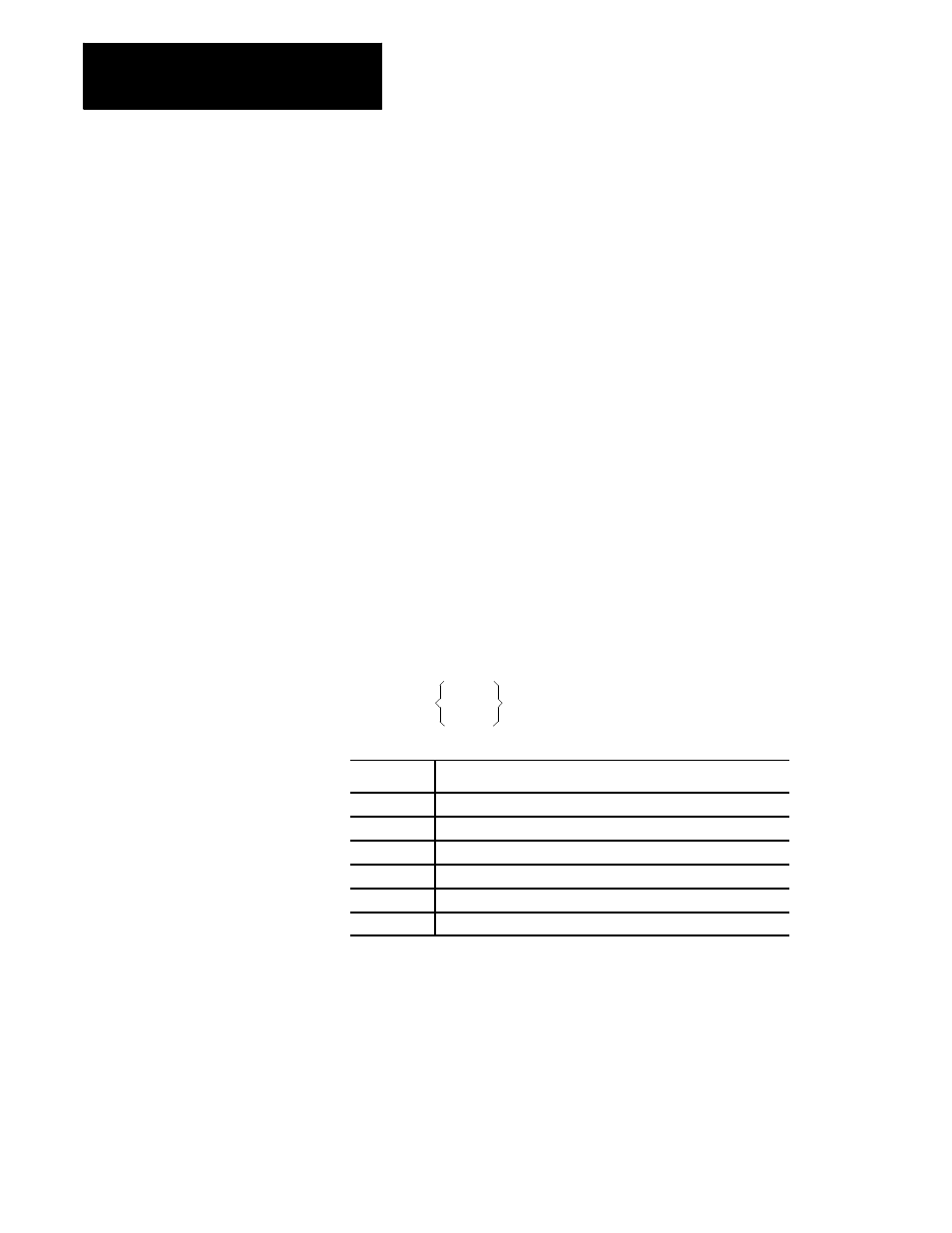

The format for the G86.1 cycle is:

G86.1X__Z__

I__K__

R__F__L__;

Q__

Where :

Is :

X

specifies location of the hole.

Z

defines the hole bottom.

Q or I, K

defines the tool shift amount.

R

defines the R point level.

F

defines the cutting feedrate.

L

defines the number of times the drilling cycle is repeated.

See page 26-7 for a detailed description of these parameters.

Important: The programmer or operator must start spindle or live tool

rotation.

(G86.1): Boring Cycle, Tool

Shift