Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 767

Chapter 30

Using a 9/Series Dual--Processing System

30-27

This boundary number should be the same as the tool geometry

number (T-word) that will be active when the tool and/or fixture is

being controlled. Refer to your system installer’s documentation for

details on which tool or fixture corresponds to which interference

boundary number (1-32).

6.

Use the up or down cursor keys to move the block cursor to the

interference area parameter to be changed. The selected field appears

in reverse video.

7.

If necessary, change the measurement units by using MDI. Units

currently used in the table are determined by the current mode of the

process (G70 inch or G71 metric).

8.

Enter the boundary area values as determined on page 30-22. Enter

values in one of two ways:

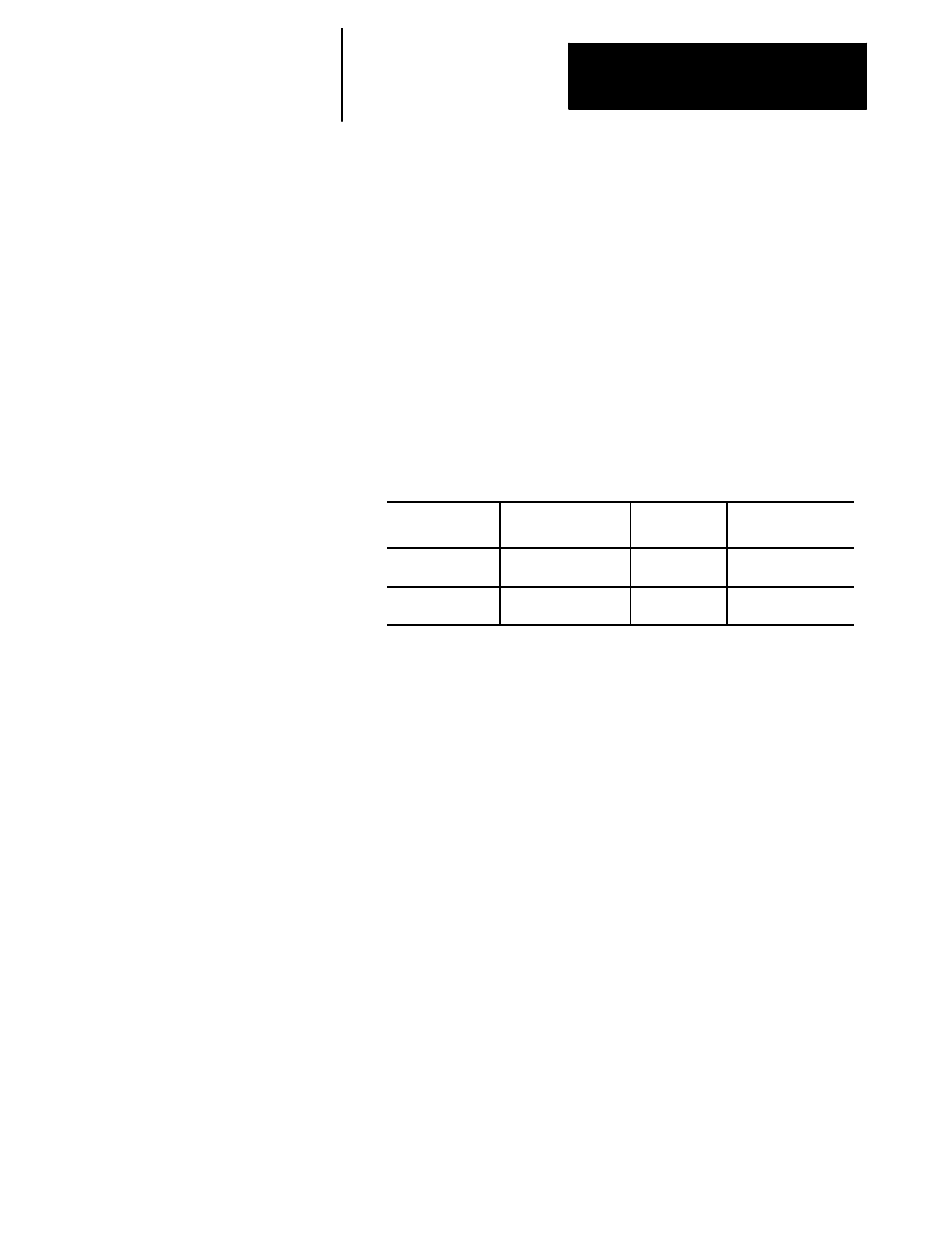

Press This

Softkey:

Then:

Press:

The New Value:

{REPLCE

VALUE}

Type in the new value.

[TRANSMIT]

replaces the old value

for that feedrate.

{ADD TO

VALUE}

Type in the new value.

[TRANSMIT]

is added to the old

value for that area.

9.

Repeat this procedure for each process until all boundaries are

entered.

You can enter data in the interference tables by programming the correct

G10 command. This section describes the use of the G10 commands.

Important: The active boundary and the value in the interference

boundary table change when a G10 code modifies the table value. Both

changes activate immediately.

When the process is in incremental mode (G91), any values entered in the

table with the G10 command are added to the currently existing offset

values. When the process is in absolute mode (G90), any values entered in

an offset table with the G10 command replace the currently existing offset

values.

Values can be entered into the table as inch or metric values. Select the

values you intend to enter by first programming the G-code that establishes

the mode you wish to use (G70 or G71).

30.5.3

Entering Interference Values

through Programming

(G10L5 and G10L6)