4 jog offset – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 325

Chapter 11

Coordinate System Offsets

11-19

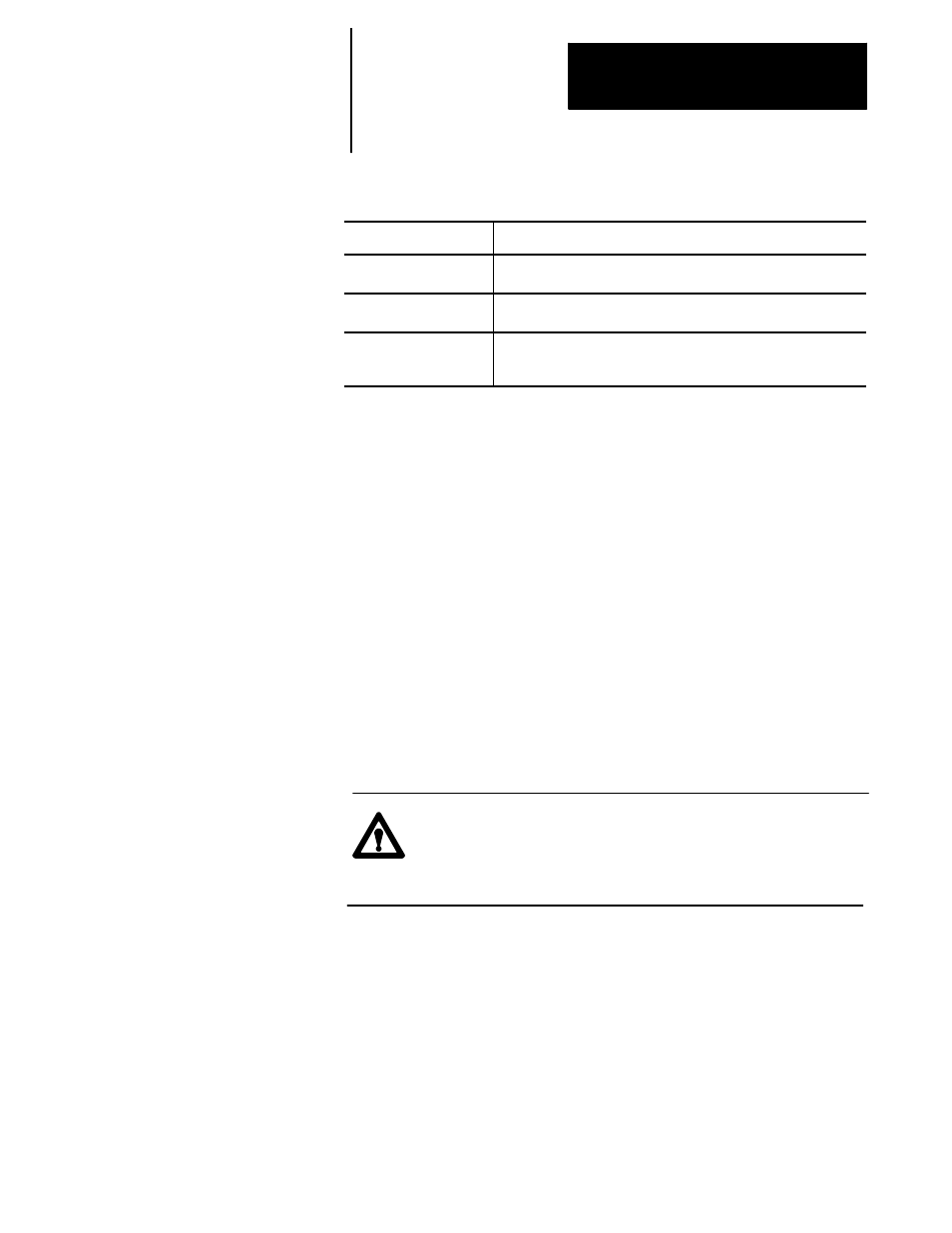

Example 11.8

Typical Set Zero Offset Application

Operation

Comment

-Manual jog-

axes are manually jogged to a location where the operator has

determined that a special operation must be performed.

-Set Zero-

operator performs a Set Zero offset to establish the work coordinate

system zero point at the current axis location

-Run program-

a generic special operation program can now be executed from the

axis coordinate position that resulted from the manual jog and Set

Zero

The set zero offset can be performed through an optional switch installed

by your system installer or through the {SET ZERO} softkey as described

on page 2-13 on using the {FRONT PANEL} softkey.

The jog offset feature lets you manually create a desired offset by jogging

the axes during an automatic or MDI operation.

Important: This feature functions only if your system installer has

supplied a special switch and the appropriate PAL programming. See the

“Jog Offsets” and “Jog-on-the-fly” PAL flags in the PAL reference manual

or refer to the documentation supplied by your system installer.

Press a special switch after interrupting an automatic or MDI operation to

activate this feature. Any manual jog moves you make are added to the

current work coordinate position as an offset. When you press cycle start

to continue execution, the jogged distance for each axis remains as a

coordinate offset for that axis.

CAUTION: Jog offsets are global. Changing from one

coordinate system to another does not cancel the offset. Do not

specify a change in coordinate systems (G54-G59) unless the

effects of the offset have been considered.

You can cancel the jog offset by programming a G92.1 command,

executing a control reset operation, executing an E-STOP reset operation,

or programming an end of program M30 or M02 command.

11.4.4

Jog Offset