Shared spindle configuration, Separate spindle configuration, 4 spindle control for dual- processing systems – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 752

Chapter 30

Using a 9/Series Dual--Processing System

30-12

For example, press

to place process 1 in cycle suspend

mode, while process 1 is waiting for process 2 to execute an M101. Later,

when you request

for process 1, the synchronization

M-code is re-activated and process 1 is again paused, waiting for process 2

to execute an M101. If, while process 1 is in cycle suspend mode, process

2 executed an M101, process 2 will pause at that synchronization block.

Pressing

for process 1 releases the pause for both process,

and they will resume program execution.

There are two basic configurations for the spindle with dual-processing

systems. These are:

Shared Spindle Configuration -- The system contains one spindle that is

controlled by both processes (in addition to any other spindles the

system may contain).

Separate Spindle Configuration -- The system contains one or more

separate spindles for each process. In some cases these spindles are on

completely separate machines.

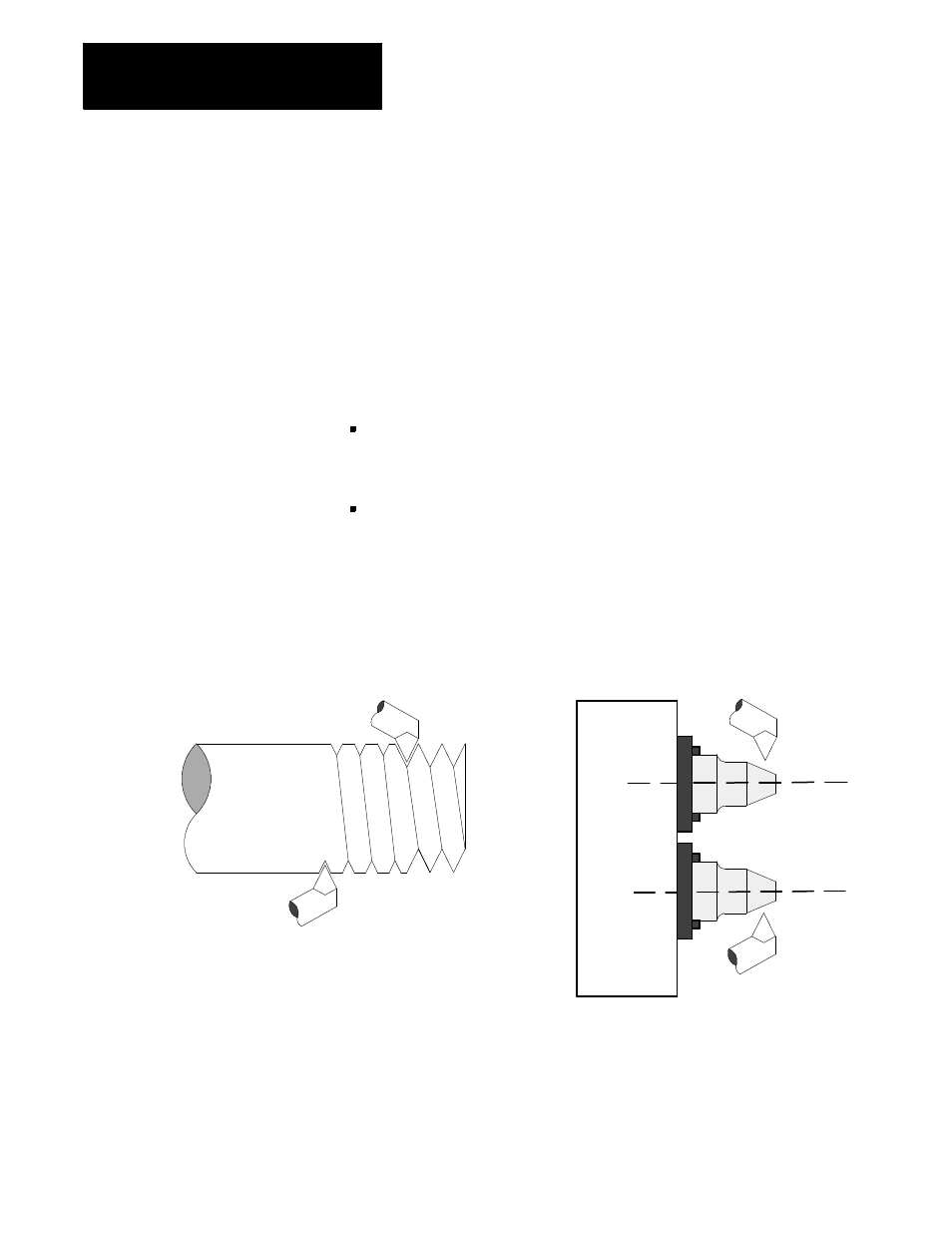

Figure 30.4

Example of Different Dual-Processing Spindle Configurations

Process 1

1st Threading Pass

Process 2

2nd Threading Pass

Shared Spindle Configuration

Process 2

Process 1

Separate Spindle Configuration

Dual-Turret Lathe

Dual-Spindle Lathe

12599-I

Both the shared and separate spindle configurations can have additional

spindles. These spindles must be assigned to only one process and cannot

be controlled by more than one process. When a process has more than

one spindle under its control, use a G12.x command to select the currently

active spindle. Refer to chapter 17 for details.

30.4

Spindle Control for

Dual- Processing Systems