Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 821

Error and System Messages

Appendix B

B-21

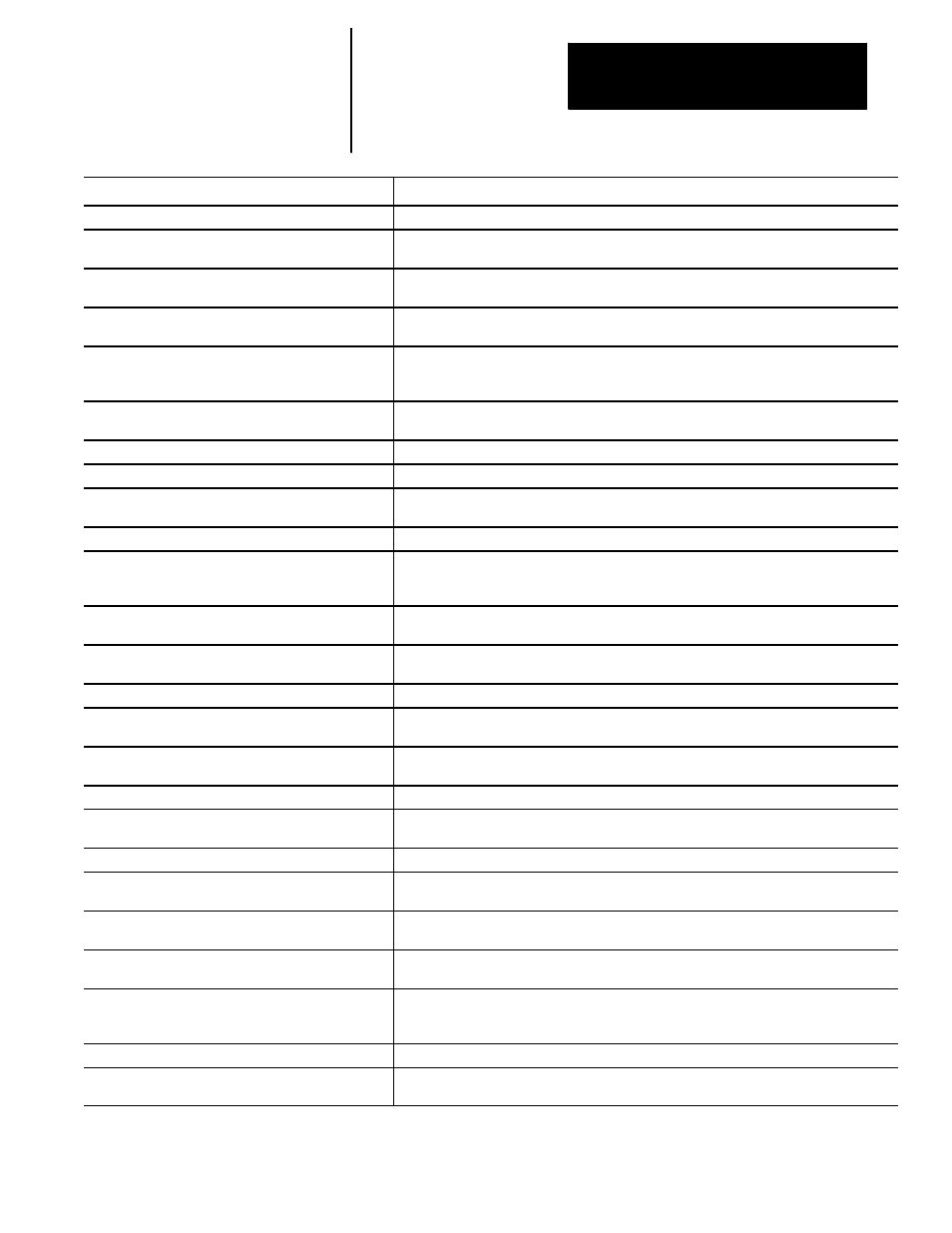

Message

Description

INVALID FIXED DRILLING AXIS

The axis selected as the drilling axis is an invalid axis for a drilling application.

INVALID FORMAT SPECIFIED IN B/DPRNT CMD

Improper format was used in the paramacro command (BPRNT or DPRNT) that outputs data to

a peripheral device.

INVALID FUNCTION ARGUMENT

An invalid paramacro argument was used in a paramacro function. The argument contains

either bad syntax or an illegal value.

INVALID G10 CODE

The format for a G10 block is not correct. Refer to your user manual for the correct format for

the G10 block that is currently being programmed.

INVALID IN ANGLED WHEEL MODE

A feature that is not available in G16.3 mode, or G16.4 mode or both has been programmed.

Refer to your grinder users manual angled-wheel grinder section for a description of features not

available on an angled-wheel grinder.

INVALID INFEED (P WORD)

Infeed value (P-word) is not in valid range. The valid range for a P-word during a threading

cycle is whole numbers 1 though 4.

INVALID INPUT VALUE

The data entered is invalid for the current operation being performed.

INVALID INTERFERENCE AREA

A G10 block has programmed a zone where the plus value is less than the minus value.

INVALID INTERFERENCE CHECK AXIS

An axis from the wrong process was AMPed. Unless a shared axis is used in the zone, the axis

defined to make up an interference area must be in the process the zone is defined for.

INVALID LATHE AXIS

An illegal code was encountered during cylindrical interpolation programming.

INVALID LIFE TYPE

The current program is attempting to enter an invalid tool life type for a tool group in the tool

management tables. Valid tool life types are type 0, 1, or 2. Tool life type is programmed in a

G10 block following a I-word.

INVALID M99 IN MAIN PROGRAM

An M99 part program rewind and auto start was programmed in the middle of the main program.

An M99 can be programmed only at the end of a part program.

INVALID MACRO COMMAND

The IS and IM commands are reserved for use by the control only for program interrupts. They

cannot be entered in a part program or MDI program.

INVALID MACRO FROM TAPE

You have programmed a paramacro command that cannot be executed from tape.

INVALID NUMBER OF POCKETS

This error occurs when using G10 L20 to enter random tool data and the number of pockets

needed for the tool is invalid.

INVALID OFFSET NUMBER

An offset number out of the range of allowable offset numbers (either too large or too small) was

programmed.

INVALID OPERATOR IN EXPRESSION

Check expressions to make sure they are correct.

INVALID OPERATOR IN PARAMACRO EXPRESSION

The control has encountered a non-mathematical operator (character) in a paramacro

expression or calculate operation.

INVALID OUTPUT FORMAT

An error occurred in G05 DH+ communications block.

INVALID PARAMACRO ARGUMENT ASSIGNMENT

An argument assignment in a block that calls a paramacro program contains either an invalid

argument specification or a syntax error was made in the argument.

INVALID PARAMETER NUMBER

An attempt was made to assign or read the value of a paramacro parameter that does not exist.

INVALID PARAMETER VALUE

An attempt was made to assign an invalid value (typically too large or too small of a value) to a

paramacro parameter.

INVALID POCKET NUMBER

An attempt was made to enter a tool pocket number that exceeds the allowable number of tool

pockets in the random tool table. This error occurs when a P-word that is too large or too small

is programmed in a G10.1L20 block.

INVALID POCKET PROFILE

An invalid pocket profile was programmed in a lathe roughing or finishing cycle.

INVALID POSITION FB TYPE

System was incorrectly AMPed with a Yaskawa type encoder (absolute or incremental) on the

position feedback device when separate position and velocity feedback devices are used.