Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 755

Chapter 30

Using a 9/Series Dual--Processing System

30-15

An error is generated and the process enters cycle stop if you attempt to

activate one of these features while one is already active in another

process. For example, if process 1 is currently performing virtual C on the

shared spindle and process 2 attempts to execute a G84 right hand tapping

block, process 2 will generate an error and enter cycle stop. Process one

will continue until completion or until it encounters a synchronization

M-code. Any attempt to change the spindle speed or direction (via M03,

M04, or M05) will have the same results.

Threading on a Shared Spindle

Simple threading (G33 or G34) and the threading cycles (G21 and G78)

can be performed on a shared spindle. Make sure that the spindle speed or

direction is not changed by process 2 (see page 30-13).

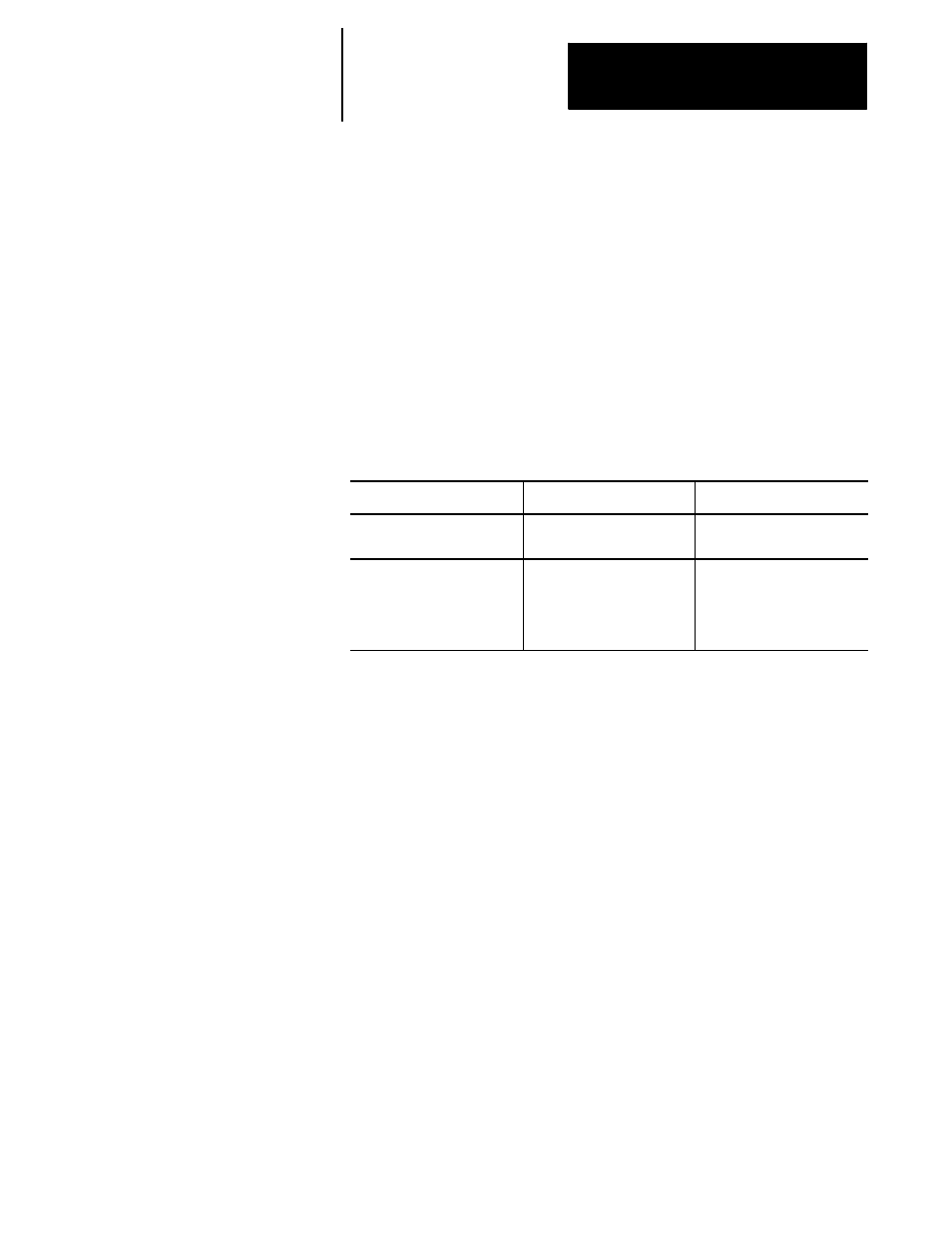

Process 1

Process 2

Spindle Operation

N15 G33 X10 Z10 F20 S100;

Synchronizes Z axis motion

with spindle for threading.

N17 M03 S200;

Will not cancel threading

synchronization on process 1;

however, it will change

threading speed or direction or

both.

Both processes can also perform threading from the same spindle.

Synchronization of the spindle will be performed from the same marker

point. Both processes can cut the same thread if the same thread lead is

programmed in both processes.

Important: When you use two processes to cut the same thread, the

position of the cutting tool has a significant impact on the thread being cut.

Both processes key off of the same spindle marker, so it is necessary to

alter the start point of one of the processes. Failure to do so results in a

multistart thread.