Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 672

Skip and Gauge Probing Cycles

Chapter 27

27-4

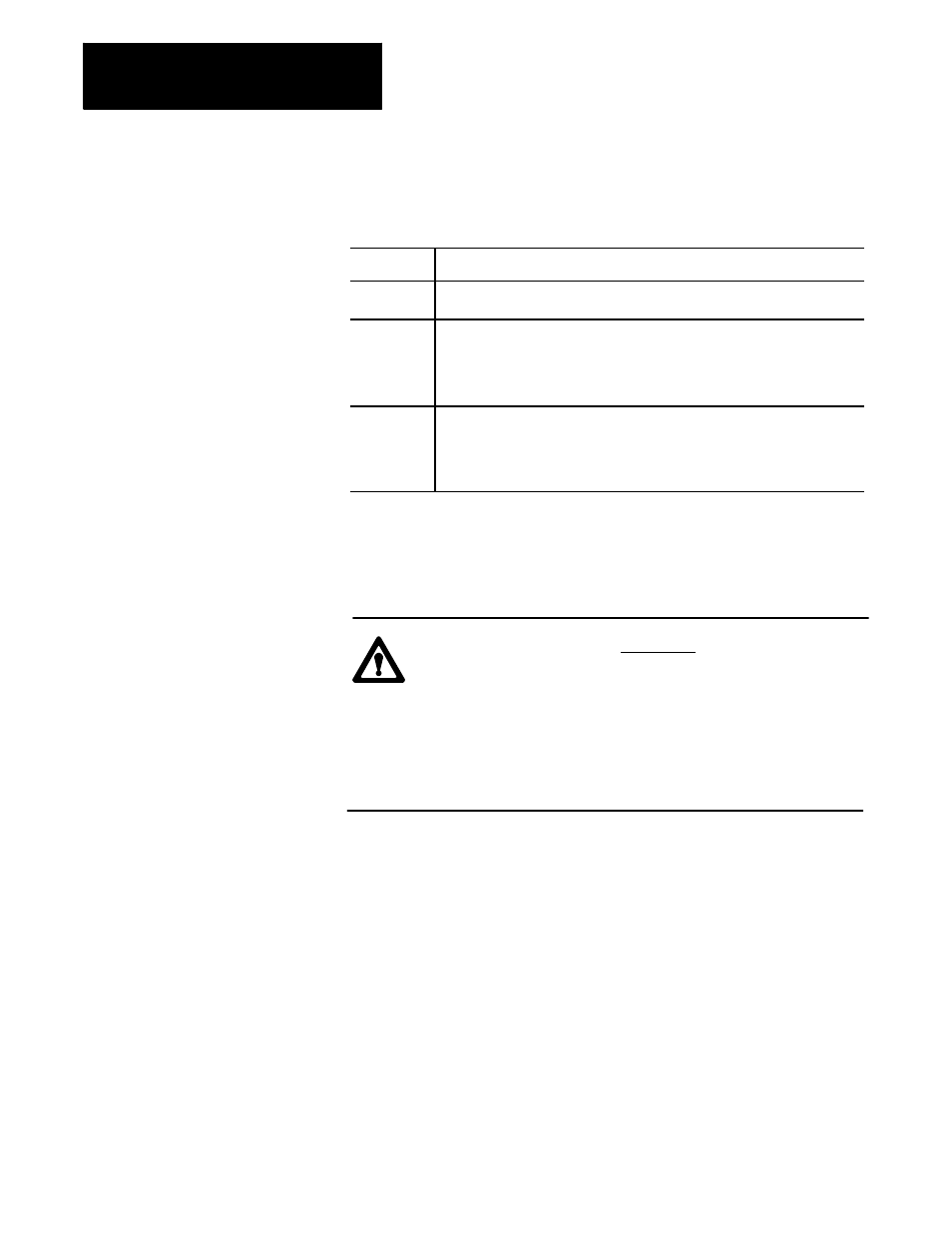

The format for any G37 skip blocks is:

G37 Z__ F__;

Where :

Is :

G37

Corresponds to any of the G-codes in the G37 series. Use the one that is

configured to respond to the current skip signal device that is being used.

X, Z

The axis on which the length offset measurement is to be taken is specified here

as either X or Z. Only one axis may be specified in a G37 block. The numeric

value following the axis name corresponds to the exact coordinate at which the

skip signal is expected to occur. This value is a signed value (+ or --) and

determines the initial direction of travel.

F

The tool gauging external skip function feedrate. If no value is entered here, the

external skip function executes at either the currently active feedrate or at the

feedrate defined for it in AMP (based on whether the AMP parameter Use AMP

Skip Feedrate

is set to ”NO”or ”YES”). A value entered here replaces the

currently active feedrate and supersedes the AMP-defined feedrate.

Important: The G37 series G-codes cannot be used to modify the tool tip

radius values. Only the tool length offset values can be modified.

The target offset value for these gauging operations is determined by the

currently active tool offset number

CAUTION: If modifying a tool length offset, the offset value

generated with this gauging operation is immediately loaded

into the offset table. Since this offset must be the currently

active offset, it becomes effective either immediately when the

next block is executed or delayed until the next block that

contains motion on the tool length axis is executed (when an

offset is activated is determined in AMP by the system

installer).

The G37 series of G-codes always produce linear motion regardless of the

current mode active at their execution. After their completion, the control

returns to the operating mode active before the skip block was read (G00,

G01, G02, G03).

The system installer determines (in AMP) a position tolerance for the G37

functions. This tolerance defines a legal range before and after the

coordinate position programmed with the axis word in the G37 block.

If the skip signal is received before the tool enters or after the tool exits the

position tolerance range, a PROBE ERROR occurs. This error appears on

the screen as a warning but does not place the control in E-Stop. Instead

the G37 block is aborted and program execution proceeds to the next

block. No modification of the tool offset table is performed.