Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 748

Chapter 30

Using a 9/Series Dual--Processing System

30-8

Synchronization M-codes are not allowed in the last block in the part

program. This can cause the part program to pause indefinitely, waiting

for the next part program block (which does not exist) to become active.

Synchronization M-codes are ignored during QuickCheck execution and

during a Mid-Program Start operation.

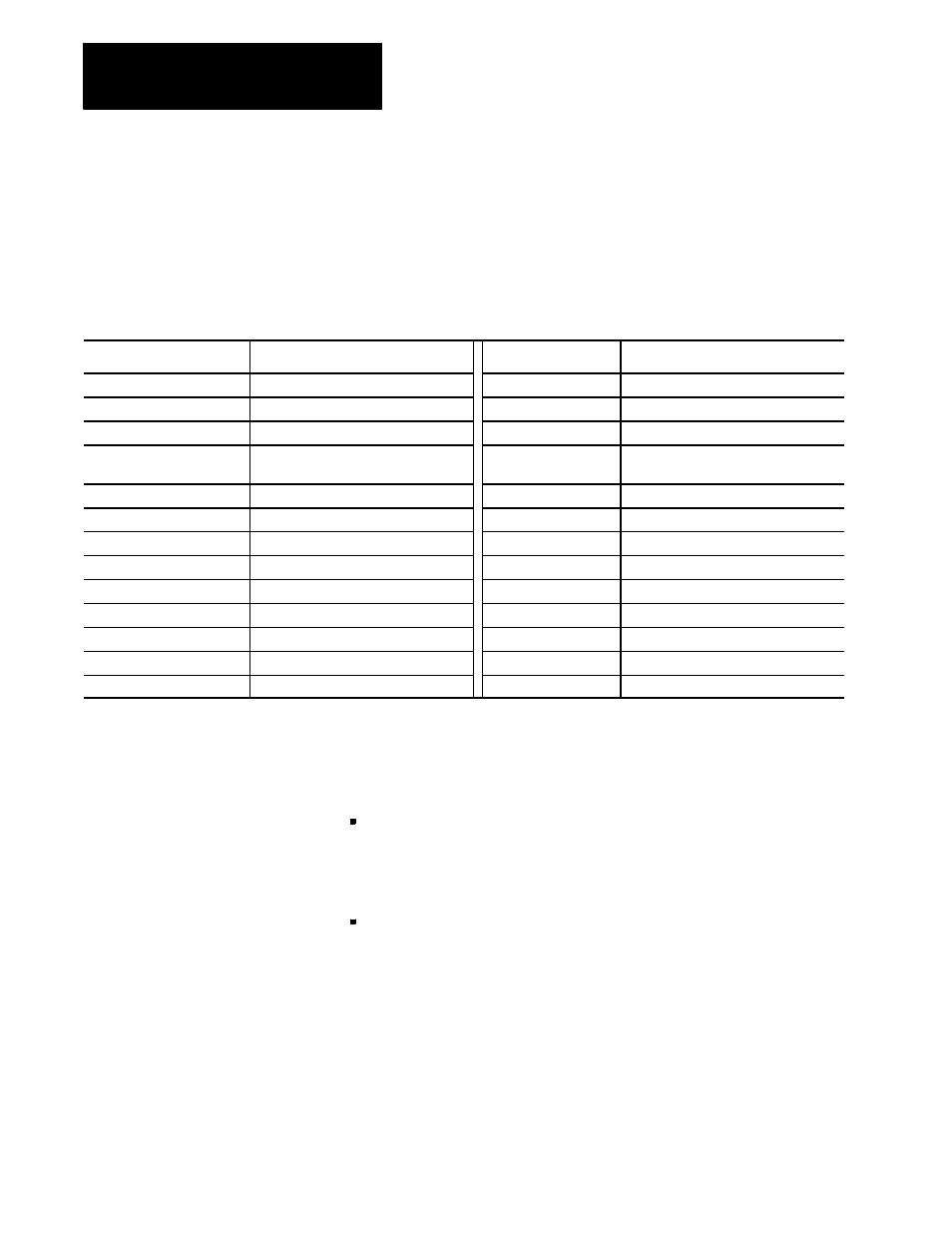

Example 30.1

Example of Synchronization for Threading (see Figure 30.3)

Process 1

Comment

Process 2

Comment

N1 G90 S500 G00 X40. Z60.; Start spindle and move to start point

N1 G90 G00 X40. Z60.;

Move to threading cycle start point

N2 G20 X28. Z25. F10.;

Start roughing shaft

N2 M100;

Wait for roughing to complete (process 1

block N5)

N3 X24.;

Roughing shaft

N4 X20.;

Roughing shaft

N5 M100;

Release process 2 block N2

N3 G21 F.5 X19. Z26.;

Start threading shaft

N6 M30;

N4 X18.;

Threading shaft

N5 X17.;

Threading shaft

N6 X16.;

Threading shaft

N7 M30;

Simple Synchronization vs Synchronization with Setup

There are two types of synchronization M-codes. They are:

M100 - M149 — Simple Synchronization. These M-codes are for

simple synchronization. When executed, this set of M-codes does not

set up any program blocks that have already been read into program

lookahead again.

M150 - M199 — Synchronization with Setup. This set of M-codes

cancels any information already in block lookahead and sets up the

block again before process execution is resumed. This second setup is

only essential when shared information is being changed from one

process to another, as in the case of the dual-processing shared

paramacro parameters.

Important: You cannot use synchronization with setup M--codes when

TTRC is active. Use one of the simple synchronization M--codes or turn

off TTRC before programming the synchronization with setup M--code.