Coordinate system offsets – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 307

Chapter

11

11-1

Coordinate System Offsets

This chapter covers the control of the coordinate systems on the 9/Series

control. G-words in this chapter are among the first programmed because

they define the coordinate systems of the machine in which axis motion is

programmed. This chapter describes:

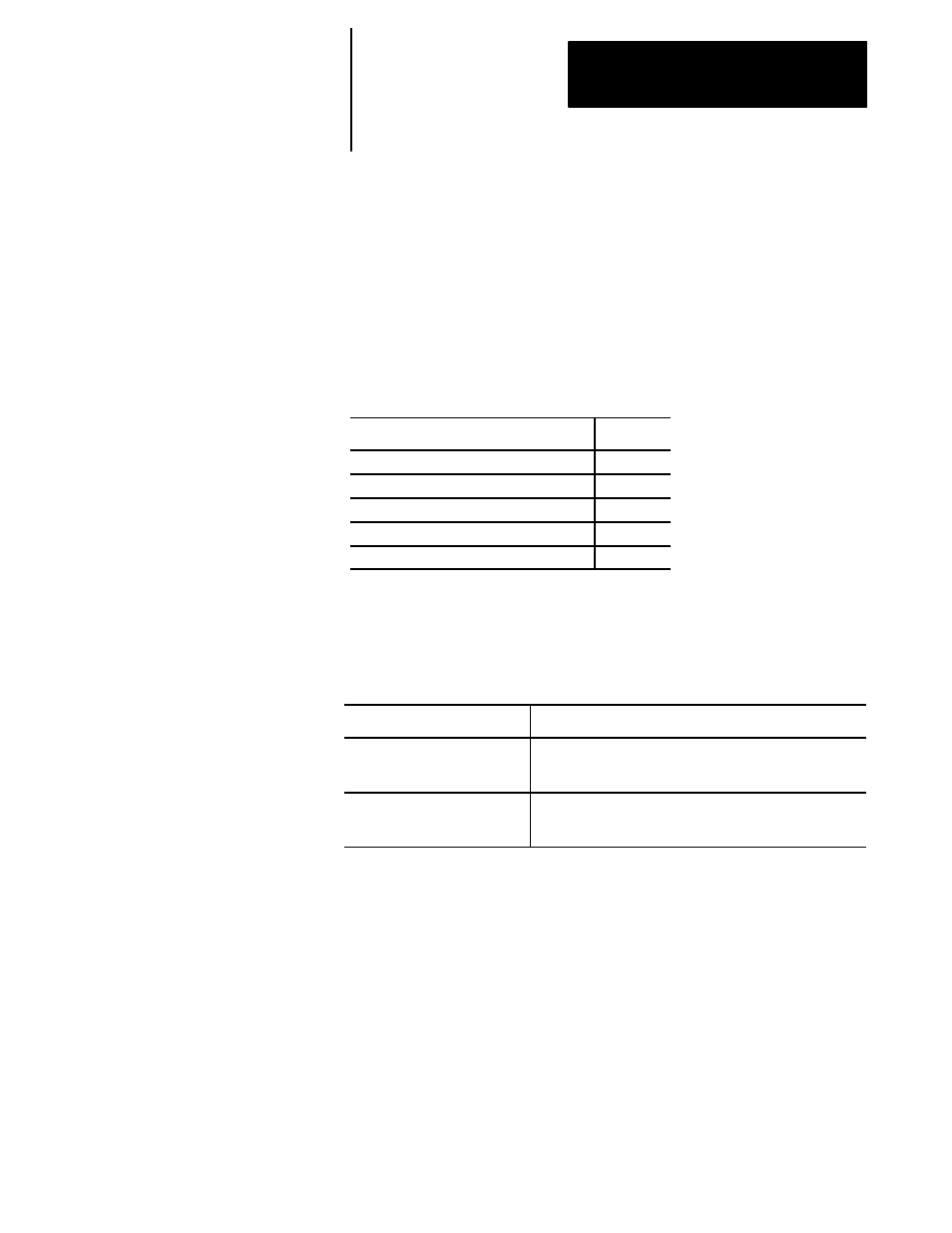

Information about:

On page:

Machine coordinate system

11-1

Preset Work coordinate systems G54-59.3

11-4

Work coordinate systems external offset

11-10

Offsetting the work coordinate systems

11-13

PAL offsets

11-22

A thorough understanding of this group makes programming easier by

allowing full control of the coordinate systems.

The 9/Series control has two types of coordinate systems.

Coordinate System:

Description:

work coordinate system

defined based on the coordinate system used in the part

drawing of a part to be cut by the machine. Programs are

usually written based on the work coordinate system.

machine coordinate system

(often referred to as the absolute

coordinate system)

unique to the individual machine tool.

The machine coordinate system is the basic coordinate system set for every

machine. It is established after completion of the machine-homing

operation. It cannot be offset or shifted in anyway. Its position is

determined in AMP by your system installer.

Important: Before you can activate any coordinate system, the machine

must be homed. The homing operation refers to the positioning of the axes

to a machine-dependent, fixed position which is called the machine home.

For more on machine homing, refer to page 4-9.

The zero point of the machine coordinate system is referenced from the

machine home point. This is done by assigning a coordinated location to

the machine home point. The home position for each axis can be given

any legal coordinates, such as 15.00, -20.0000, or -2.256.

11.0

Chapter Overview

11.1

Machine (Absolute)

Coordinate System