Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 426

Spindles

Chapter 17

17-28

When synchronization is active, any part program commands

destined for the follower spindle (i.e., M03, M03.2,

M03.3...G12.1, G12.2, and G12.3) will cause an error. On a

multiprocess configuration, this is true of either process.

On a multiprocess 9/Series, the process controlling the controlling

spindle also controls the follower spindle when spindle

synchronization is active. If it is unable to obtain control, an error

results: UNABLE TO SYNCH IN CURRENT MODE.

Important: Typically, the programmed speed of the controlling spindle

dictates the speed of the follower spindle. In the event that the

programmed speed exceeds the maximum or drops below the minimum

allowable values for the synchronized pair, the spindle speed will be

restricted to those allowable values, as shown on page 17-28.

the example below shows what will happen when:

no overlap occurs between the controlling and follower

spindles’gear ranges

the controlling spindle has a higher gear range than the

follower spindle

the controlling spindle has a lower gear range than the

follower spindle

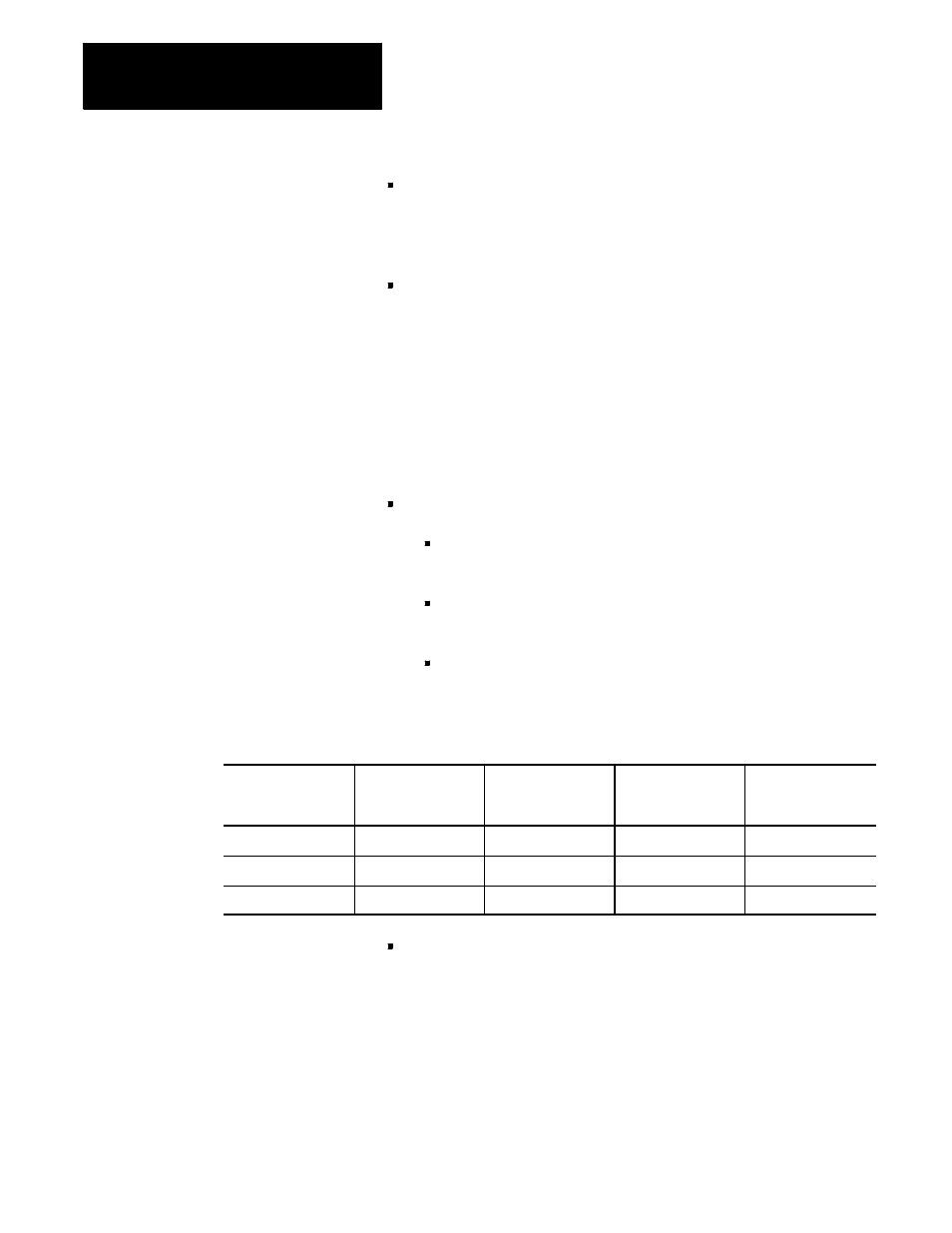

Example 17.6

Valid Gear Ranges for Synchronized Spindles

Controlling Spindle

Gear Range

(RPM)

Follower Spindle

Gear Range

(RPM)

Requested

Spindle Speed

(RPM)

Valid Programmed

Spindle Speeds

(RPM)

Spindles will

Synchronize at

(RPM):

1000 to 3000

100 to 300

1500

None

N/A

1000 to 3000

800 to 1500

1800

1000 to 1500

1500

1000 to 3000

1800 to 3200

1500

1800 to 3000

1800

in a multiprocess system, if the spindles are synchronized, and an

end--of--program is reached on the process synchronizing the

spindles, both spindles will obey the end--of--program commands

and synchronization is disabled.

END OF CHAPTER