Rockwell Automation 1747-PT1, D1747NP002 Hand-Held Terminal User Manual

Page 469

Appendix D

Estimating Scan Time

D–3

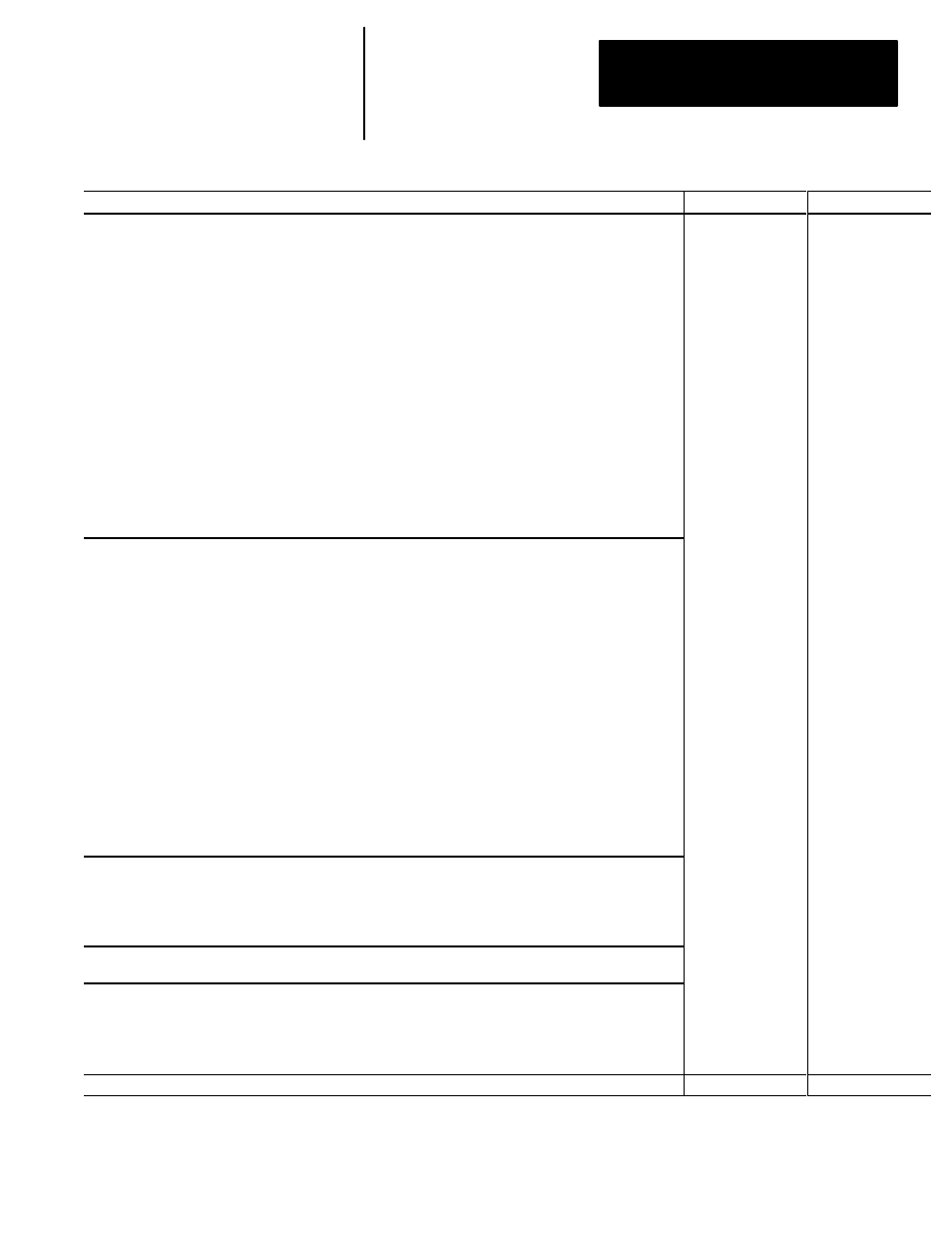

Worksheet A — Estimating the Scan Time of Your Fixed Controller

Procedure

Min Scan Time

Max ScanTime

1.

Estimate your input scan time (

µ

s).

A.

Determine the type of controller that you have.

If you have a 20 I/O processor, write 313 on line (a).

If you have a 30 or 40 I/O processor, write 429 on line (a).

a.)________

B.

Calculate the processor input scan of your discrete input modules.

Number of 8 point modules

________ x 197 =

b.)________

Number of 16 point modules

________ x 313 =

c.)________

Number of 32 point modules

________ x 545 =

d.)________

C.

Calculate the processor input scan of your specialty I/O modules.

Number of 1/4 DCM or analog combo

________ x 652 =

e.)________

Number of 1/2 DCM, analog input, or 1746–HS

________ x 1126 =

f.) ________

Number of 3/4 DCM

________ x 1600 =

g.)________

Number of full DCM, BASIC, or 1747–DSN

________ x 2076 =

h.)________

Number of 1747–KE

________ x 443 =

i.) ________

D.

Add lines a through i. Place this value on line (j).

Add 101 to the value on line (j). This sum is your minimum input scan time.

j.)________ + 101 =

E.

Calculate your maximum input scan time:

Maximum input scan time = Minimum scan time + (Number of specialty I/O modules x 50)

F.

Calculate the Forced Input Overhead: Forced Input Overhead =

(Number of input modules x 180) + 140 per additional word for multi–word modules (e.g. DCM, analog, DSN)

_________

_________

_________

2.

Estimate your output scan time (

µ

s).

A.

Determine the type of controller that you have.

If you have a 20 I/O processor, write 173 on line (a).

If you have a 30 or 40 I/O processor, write 272 on line (a).

a.)________

B.

Calculate the processor output scan of your discrete output modules.

Number of 8 point modules

________ x 173 =

b.)________

Number of 16 point modules

________ x 272 =

c.)________

Number of 32 point modules

________ x 470 =

d.)________

C.

Calculate the processor output scan of your specialty I/O modules.

Number of 1/4 DCM or analog combo

________ x 620 =

e.)________

Number of 1/2 DCM, analog output, or 1746–HS ________ x 1028 =

f.) ________

Number of 3/4 DCM

________ x 1436 =

g.)________

Number of full DCM, BASIC, or 1747–DSN

________ x 1844 =

h.)________

D.

Add lines a through h. Place this value on line (i).

Add 129 to the value on line (i). This sum is your minimum output scan time.

i.)________ + 129 =

E.

Calculate your maximum output scan time:

Maximum output scan time = Minimum scan time + (Number of specialty I/O modules x 50)

F.

Calculate the Forced Output Overhead: Forced Output Overhead =

(Number of output modules x 172) + 140 per additional word for multi–word modules (e.g. DCM, analog, DSN)

_________

_________

_________

3.

Estimate your program scan time. This estimate assumes operation of all instructions once per operating scan.

A.

Count the number of rungs in your APS program. Place value on line (a).

B.

Multiply value on line (a) by 1.

a.)________ x 1 =

C.

Calculate your program execution time when all instructions are true. (See appendix A to do this.)

4.

Add the values in the minimum and maximum scan time columns.

__________

__________

_________

__ subtotal

_________

_________

_________ subtotal

5.

Add processor overhead time (178 for min. scan time; 278 for max. scan time) to the subtotals estimated in step 4.

Use these new subtotals to calculate communication overhead in step 6.

+ 178

__________ subtotal

+ 278

_________ subtotal

6.

Estimate your communication overhead:

A.

Calculate the background communication overhead: multiply the subtotal for minimum scan time (estimated in

step 5) by 1; multiply the subtotal for maximum scan time by 1.140 (max. value accounts for active DH–485 link).

B.

Calculate the foreground communication overhead: for minimum scan time add 0; for maximum scan time

add 2310. (Maximum scan time accounts for programmer being attached to processor.)

C.

Convert

µ

secs. to msecs., divide by 1000.

x 1.000

__________

µ

secs.

+ 0

__________

µ

secs.

/ 1000

x 1.140

_________

µ

secs.

+ 2310

_________

µ

secs.

/ 1000

Estimated minimum and maximum scan times for your fixed controller application:

msecs.

msecs.