Online data changes – Rockwell Automation 1747-PT1, D1747NP002 Hand-Held Terminal User Manual

Page 358

Chapter 26

PID Instruction

26–14

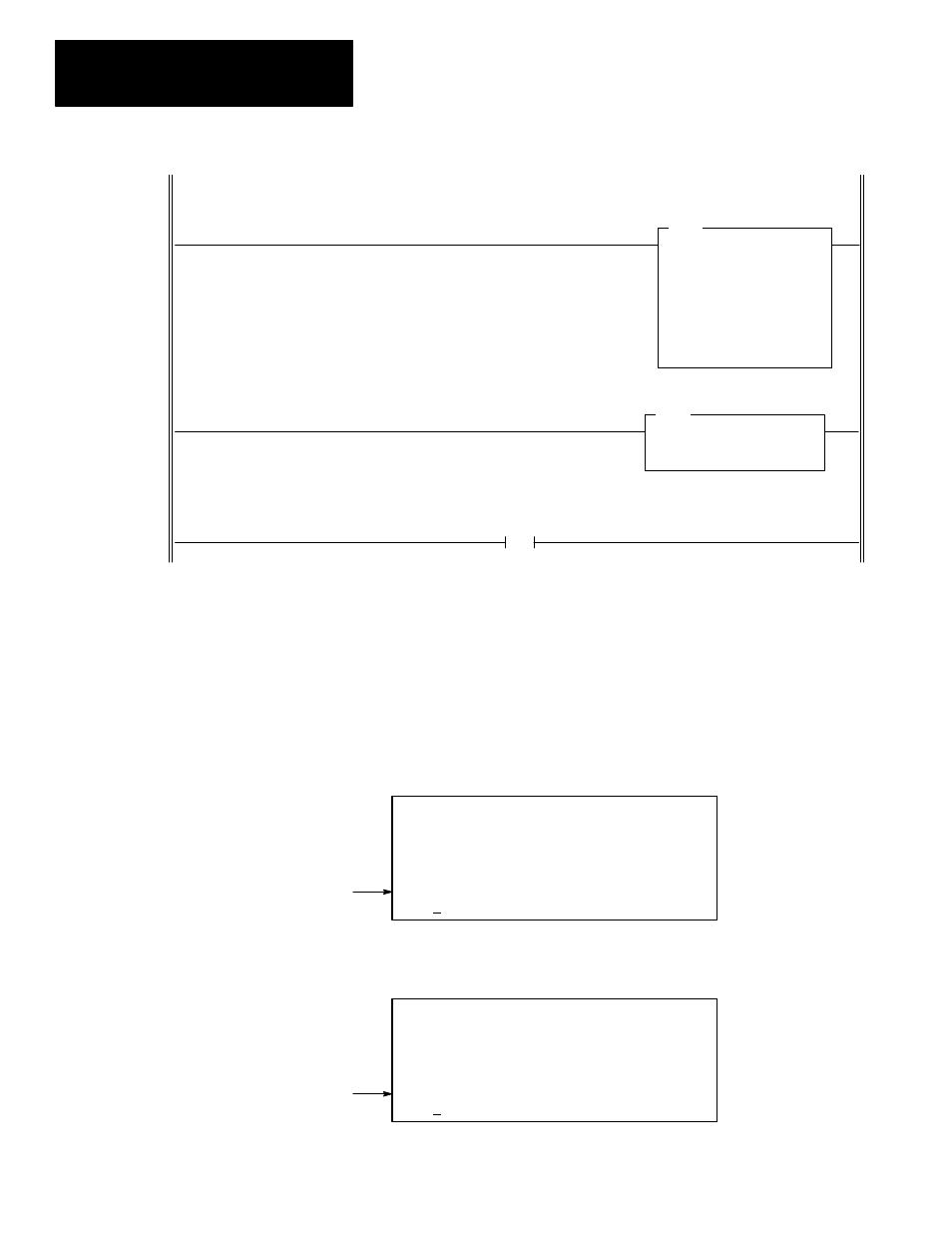

IOM

IMMEDIATE OUT w MASK

Slot

O:1.0

Mask

FFFF

END

Rung 3:6

Rung 3:5

SCL

SCALE

Source

N10:29

0

Rate [/10000]

15239

Offset

6242

Dest

O:1.0

0

The PID control variable is the input for the scale instruction. The PID instruction guarantees that the CV remains within

the range of 0 to 16383. This value is to be scaled to the range of 6242 to 31208, which represents the numeric range

that is needed to produce 4 to 20mA analog output signal.

This rung immediately updates the analog output card that is driven by the PID control variable value.

You can monitor PID parameters and status bits when you are online under

the monitor function. You can also change data in any processor mode.

The following displays appear when you press the Zoom key with the cursor

on the PID instruction while monitoring online. Note that in the first display

you can change the mode from auto to manual and vice versa.

In the auto mode, you can also change the gain parameter:

F1

F2

F3

F4

F5

ZOOM on PID –(PID)– 1/2 2.0.0.0.1

NAME: PROP INT DERIV MODE: AUTO

GAIN: 25 [/10] OUT LIM: 5% ,95%

RESET: 10 [/10 M/R] DEADBND: 5

RATE: 1 [/100 MIN] OUTPUT: 0%

SETPOINT: 500 PROCESS: 0

ENTER GAIN: 25 PRG

NEXT PG MANUAL

In the manual mode, you can change the maximum output percent:

F1

F2

F3

F4

F5

ZOOM on PID –(PID)– 1/2 2.0.0.0.1

NAME: PROP INT DERIV MODE: MANUAL

PROCESS: 0 SETPOINT: 500

OUTPUT: 95%

MIN OUT: 5% MAX OUT: 95%

ENTER OUTPUT PCT: 95 PRG

NEXT PG AUTO

Online Data Changes