The pid concept – Rockwell Automation 1747-PT1, D1747NP002 Hand-Held Terminal User Manual

Page 347

Chapter 26

PID Instruction

26–3

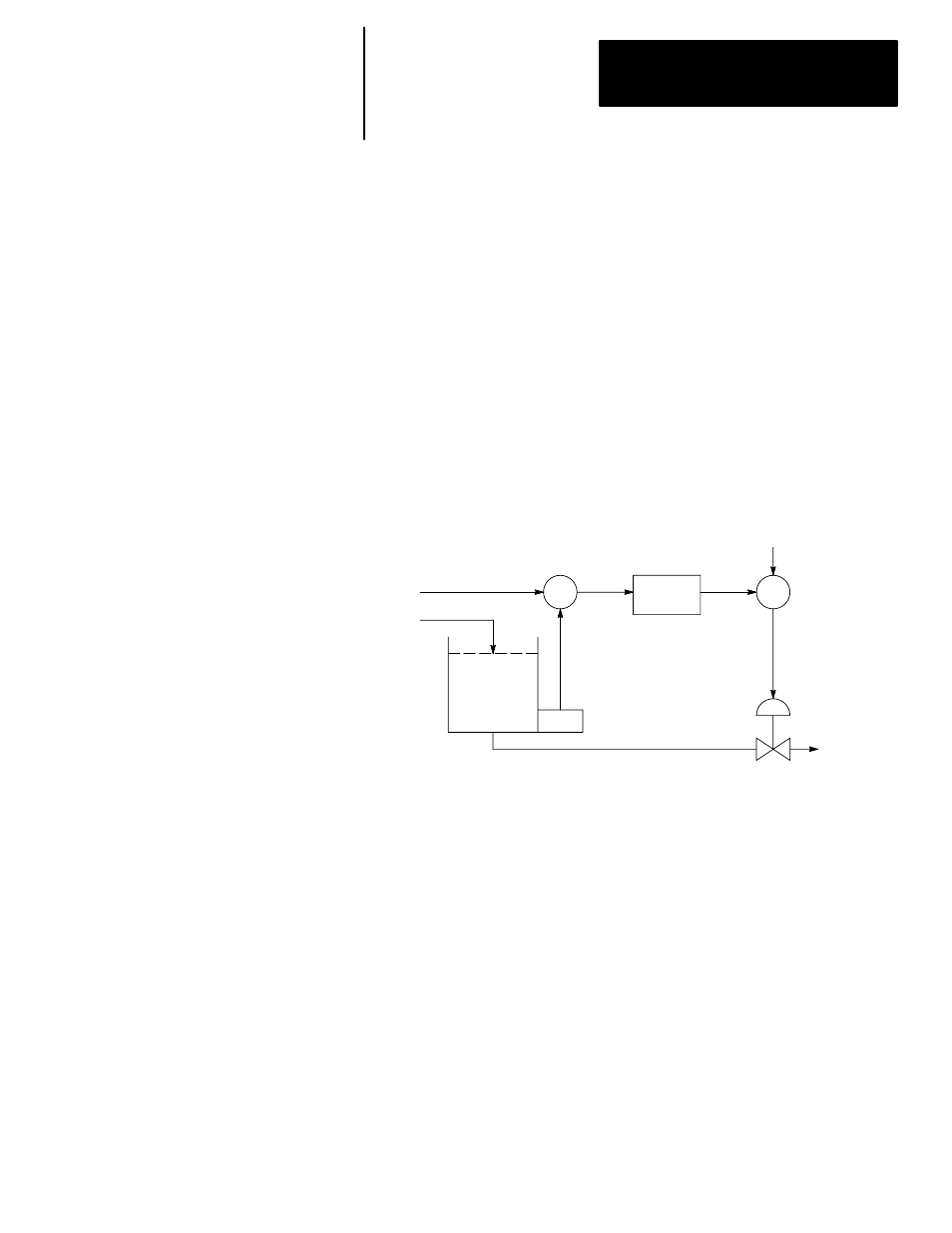

The PID instruction normally controls a closed loop using inputs from an

analog input module and providing an output to an analog output module.

For temperature control, you can convert the analog output to a time

proportioning on/off output for driving a heater or cooling unit. An example

appears on pages 26–20 and 26–22.

The PID instruction can be operated in the timed mode or the STI mode. In

the timed mode, the instruction updates its output periodically at the rate you

set. In the STI mode, the instruction should be placed in an STI interrupt

subroutine. It will then update its output every time the STI subroutine is

scanned. The STI time interval and the PID loop update rate must be the

same in order for the equation to execute properly.

PID closed loop control holds a process variable at a desired set point. A

flow rate/fluid level example is shown below.

∑

∑

PID

Equation

FFWD

or Bias

Control

Output

Level

Detector

Process

Variable

Error

Set Point

Flow Rate

Control Valve

The PID equation controls the process by sending an output signal to the

control valve. The greater the error between the setpoint and process

variable input, the greater the output signal, and vice versa. An additional

value (feedforward or bias) can be added to the control output as an offset.

The result of PID calculation (control variable) will drive the process

variable you are controlling toward the set point.

The PID Concept