Rockwell Automation 1747-PT1, D1747NP002 Hand-Held Terminal User Manual

Page 357

Chapter 26

PID Instruction

26–13

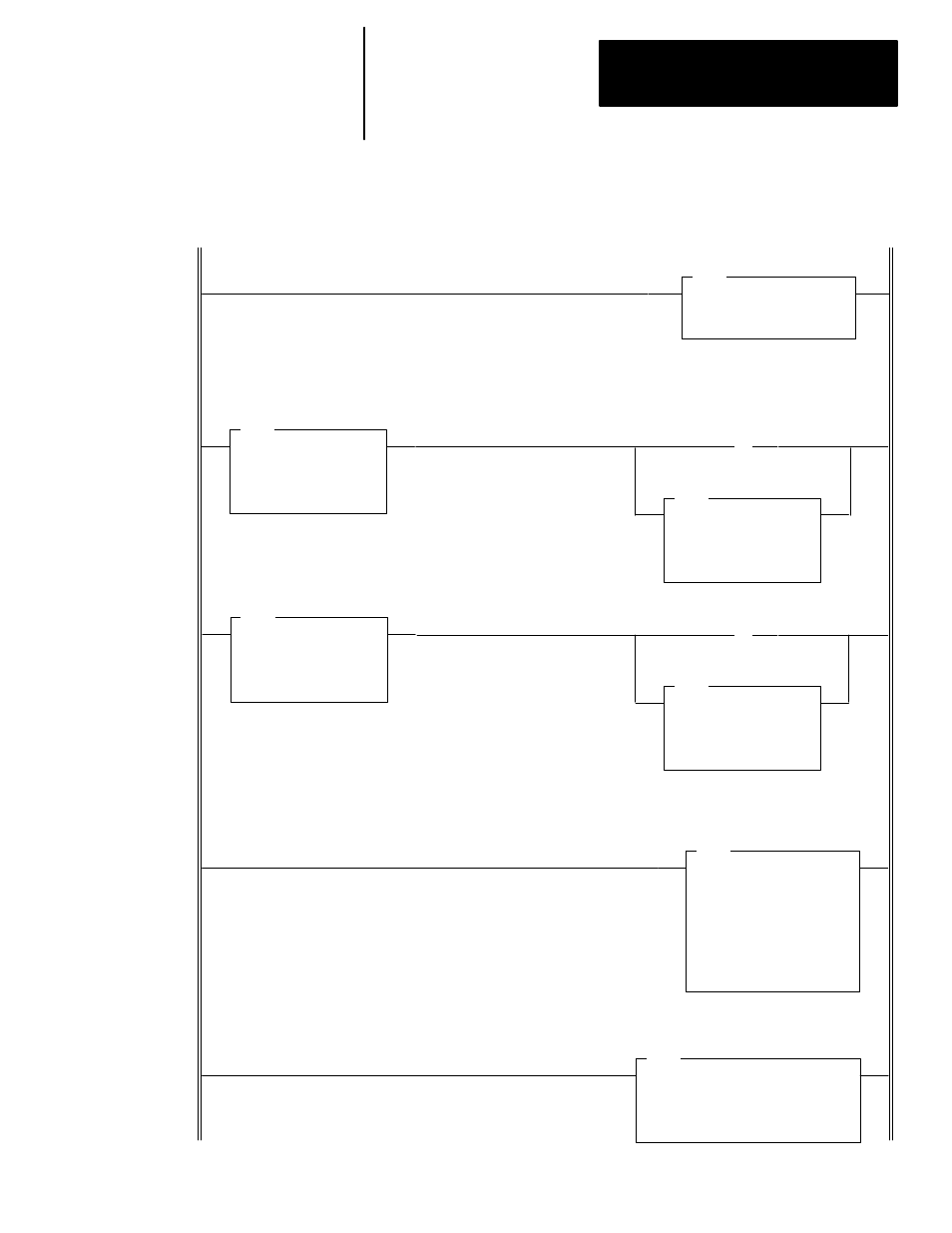

The following ladder diagram shows a typical PID loop that is programmed

in the STI mode. This example (in APS format) is provided primarily to

show the proper scaling techniques. It shows a 4 to 20mA analog input and a

4 to 20mA analog output.

SCL

SCALE

Source

I:1.0

0

Rate [/10000]

12499

Offset

–4096

Dest

N10:28

0

LES

LESS THAN

Source A

I:1.0

0

Source B

3277

GRT

GREATER THAN

Source A

I:1.0

0

Source B

16384

MOV

MOVE

Source

3277

Dest

I:1.0

0

IIM

IMMEDIATE IN w MASK

Slot

I:1.0

Mask

FFFF

(L)

B3

0

This rung immediately updates the analog input used for PV.

Rung 3:0

Rung 3:1

Rung 3:2

Rung 3:3

Rung 3:4

These two rungs ensure the analog input value to be scaled remains within the limits of 3277 to 16384. This is necessary to

prevent “out of range” conversion errors in both the SCL and PID instructions. The latch bits can be used elsewhere in your

program to identify the particular out of range condition that occurred.

Under range

MOV

MOVE

Source

16384

Dest

I:1.0

0

(L)

B3

1

Over range

The source to be scaled is the input I:1 and its destination is the process variable of the PID instruction. These values are

calculated knowing that the input range is 3277 to 16384, while the scaled range (PV) is 0 to 16383.

PID

PID

Control Block

N10:0

Process Variable

N10:28

Control Variable

N10:29

Control Block Length

23