Runtime errors – Rockwell Automation 1747-PT1, D1747NP002 Hand-Held Terminal User Manual

Page 355

Chapter 26

PID Instruction

26–11

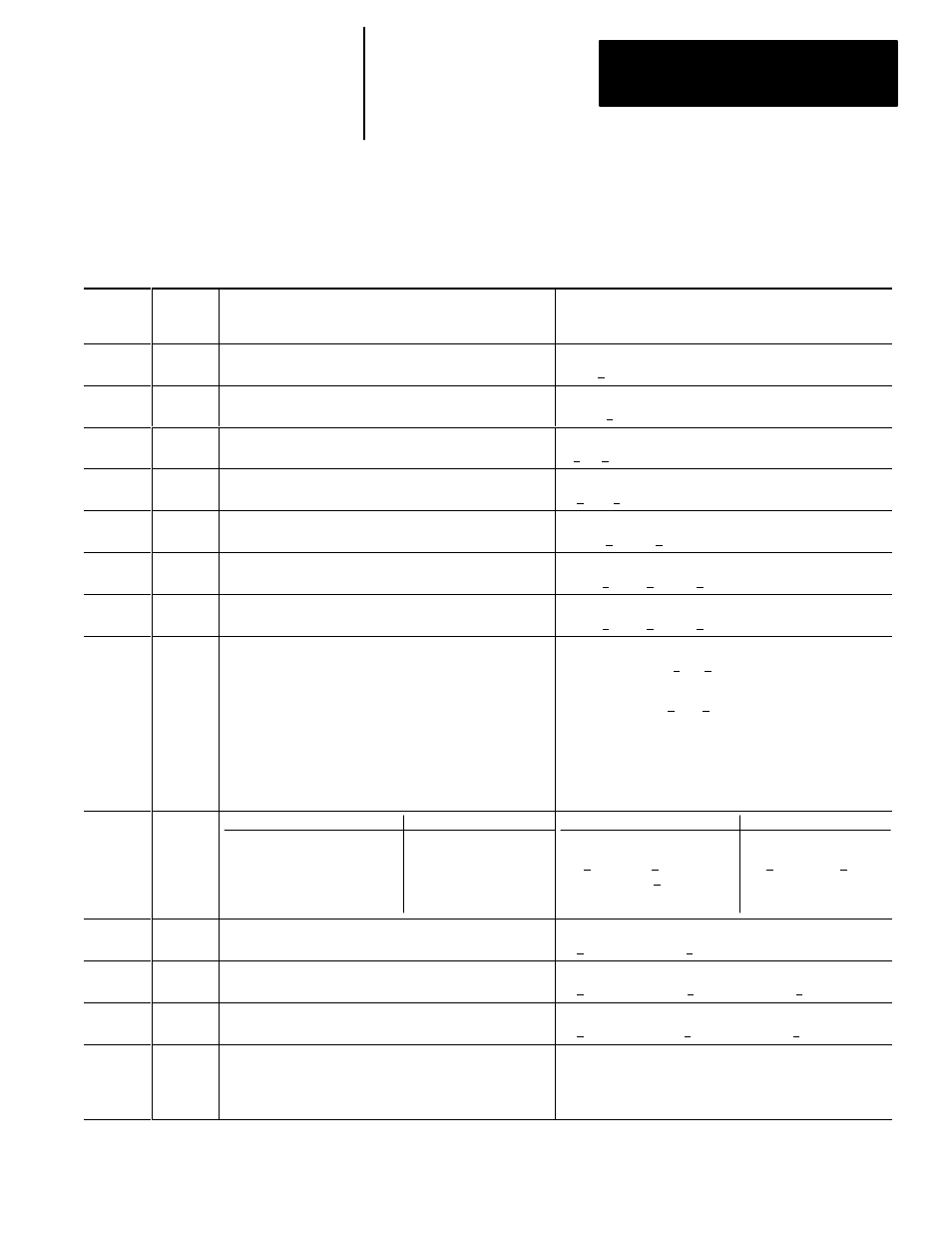

Error code 0036 appears in the status file (S:6) when a PID instruction

runtime error occurs. Code 0036 covers the following PID error conditions,

each of which has been assigned a unique single byte code value that appears

in the MSbyte (most significant byte or upper 8 bits) of the second word

(word 1) of the PID control block.

Error

Code

(Decimal)

Error

Code

(Hex)

Description of Error Condition or Conditions

Corrective Action

4352

11H

1) Loop update time D

t

> 255, or

2) Loop update time D

t

= 0

Change loop update time D

t

to

0 < D

t

< 255

4608

12H

1) Proportional gain K

c

> 255, or

2) Proportional gain K

c

= 0

Change proportional gain K

c

to

0 < K

c

< 255

4864

13H

Integral gain (reset) T

i

> 255

Change integral gain (rate) T

i

to

0 < T

i

< 255

5120

14H

Derivative gain (rate) T

d

> 255

Change derivative gain (rate) T

d

to

0 < T

d

< 255

8448

21H

1) Scaled setpoint max Smax > 16383, or

2) Scaled setpoint max Smax < –16383

Change scaled setpoint max Smax to

–16383 < Smax < 16383

8704

22H

1) Scaled setpoint min Smin > 16383, or

2) Scaled setpoint min Smin < –16383

Change scaled setpoint min Smin to

–16383 < Smin < Smax < 16383

8960

23H

Scaled setpoint min Smin > Scaled setpoint max Smax

Change scaled setpoint min Smin to

–16383 < Smin < Smax < 16383

12544

31H

If you are using setpoint scaling and Smin >

setpoint SP > Smax, or

If you are not using setpoint scaling and 0 >

setpoint SP > 16383,

then during the initial execution of the PID loop, this error occurs

and bit 11 of word 0 of the control block is set. However, during

subsequent execution of the PID loop if an invalid loop setpoint

is entered, the PID loop continues to execute using the old

setpoint, and bit 11 of word 0 of the control block is set.

If you are using setpoint scaling, then change the

setpoint SP to Smin < SP < Smax, or

If you are not using setpoint scaling, then change

the setpoint SP to 0 < SP < 16383.

16640

41H

Scaling Selected Scaling Deselected

1) Deadband < 0, or 1) Deadband < 0, or

2) Deadband > 2) Deadband > 16383

(Smax - Smin), or

3) Deadband > 16383

Scaling Selected Scaling Deselected

Change deadband to Change deadband to

0 < deadband < 0 < deadband <

(Smax – Smin) < 16383

16383

20736

51H

1) Output high limit < 0, or

2) Output high limit > 100

Change output high limit to

0 < output high limit < 100

20992

52H

1) Output low limit < 0, or

2) Output low limit > 100

Change output low limit to

0 < output low limit < output high limit < 100

21248

53H

Output low limit > output high limit

Change output low limit to

0 < output low limit < output high limit < 100

24576

60H

PID is being entered for the second time. (PID loop was inter-

rupted by an I/O interrupt, which is then interrupted by the PID STI

interrupt.)

You have at least three PID loops in your program: One in the

main program or subroutine file, one in an I/O interrupt file, and

one in the STI subroutine file. You must alter your ladder program

and eliminate the potential nesting of PID loops.

Runtime Errors