IAI America TT-C3 User Manual

Page 41

31

INTELLIGENT ACTUATOR

Chapter 1 Installation

2.

Speci

¿

cations

(4) Use example

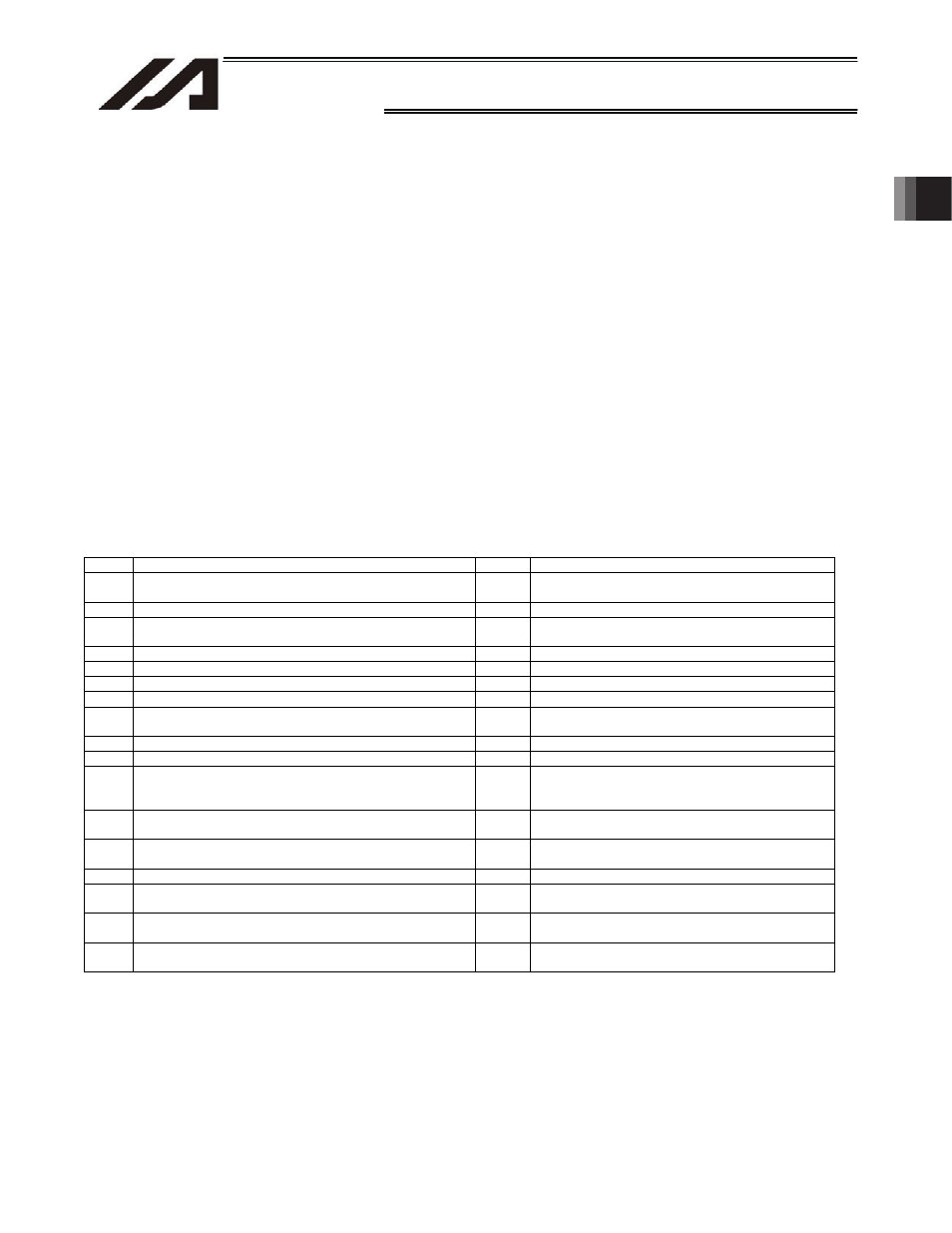

The following is a setting example of assigning the system IOs to external DIOs as shown below

when the external DIOs are assigned to input port Nos. 16 to 31 and output port Nos. 316 to 331

(default settings: the external DIOs are normally assigned to these ports before shipment).

Settings that allow the panel window LEDs (RDY, ALM, EMG, HPS) to continue functioning

normally are explained.

Input port No. 16 = Program start number (ON edge) (specified by BCD)

Input port No. 17 = Servo ON signal

Input port Nos. 18 to 23 = Start program number

Input port No. 24 = Error reset (ON edge)

Input port No. 25 = Home return of all valid axes (ON edge)

Output port No. 316 = Error of operation-cancellation level or higher (ON)

Output port No. 317 = READY output (PIO trigger program operation permitted)

Output port No. 318 = Emergency stop output (ON)

Output port No. 319 = Output during automatic operation

Output port No. 320 = Output if all valid axes completed home return (coordinates have been

confirmed)

Output port Nos. 321 to 323 = Output when axis 1 to 3 servos are ON

I/O Parameter Settings

No. Parameter

name

Settings

Remarks

30

Input function selection 000

1

1 (default value) = Program start signal (ON edge)

(specified by BCD)

32

Input function selection 002

1

1 = Servo ON

37

to 42

Input function selection 007 to 012

1

1 (default value) = Start program number

43

Input function selection 013

2

2 = Error reset (ON edge)

45

Input function selection 015

1

1 = Home return of all valid axes (ON edge)

283

Physical input port number for input function selection 000

16

Input port number = 16

285

Physical input port number for input function selection 002

17

Input port number = 17

290

to 295

Physical input port number for input function selection 007 to

physical input port number for input function selection 012

18

to 23

Input port number = 18 to 23

296

Physical input port number for input function selection 013

24

Input port number = 24

298

Physical input port number for input function selection 015

25

Input port number = 25

315

to 330

Physical input port number for output function selection 300

(area 2) to physical input port number for output function

selection 307 (area 2)

316

to 323

Output port numbers = 316 to 323

331

Output function selection 300 (area 2)

1

1 = Error of operation-cancellation level or higher

(ON)

332

Output function selection 301 (area 2)

1

1 = READY output

(PIO trigger program operation permitted)

333

Output function selection 302 (area 2)

1

1 = Emergency stop output (ON)

334

Output function selection 303 (area 2)

2

2 = Output during automatic operation

(Other parameter No. 12)

335

Output function selection 304 (area 2)

2

2 = Output if all valid axes completed home return

(coordinates have been confirmed)

336

to 338

Output function selection 305 (area 2) to output function

selection 307 (area 2)

2

2 = Output when axis 1 to 3 servos are ON

(system monitor task output)

[Notes]

x If input function selection 000 (start) is assigned to a different input port, the start switch on the

front panel will no longer function as the “program start signal.”

x If any of input function selections 007 to 013 (digital switches) is assigned to a different input

port, the digital program selector switch on the front panel will no longer function as the “start

program number.”