Axis-specific parameters, Appendix – IAI America TT-C3 User Manual

Page 310

300

INTELLIGENT ACTUATOR

Appendix

Appendix

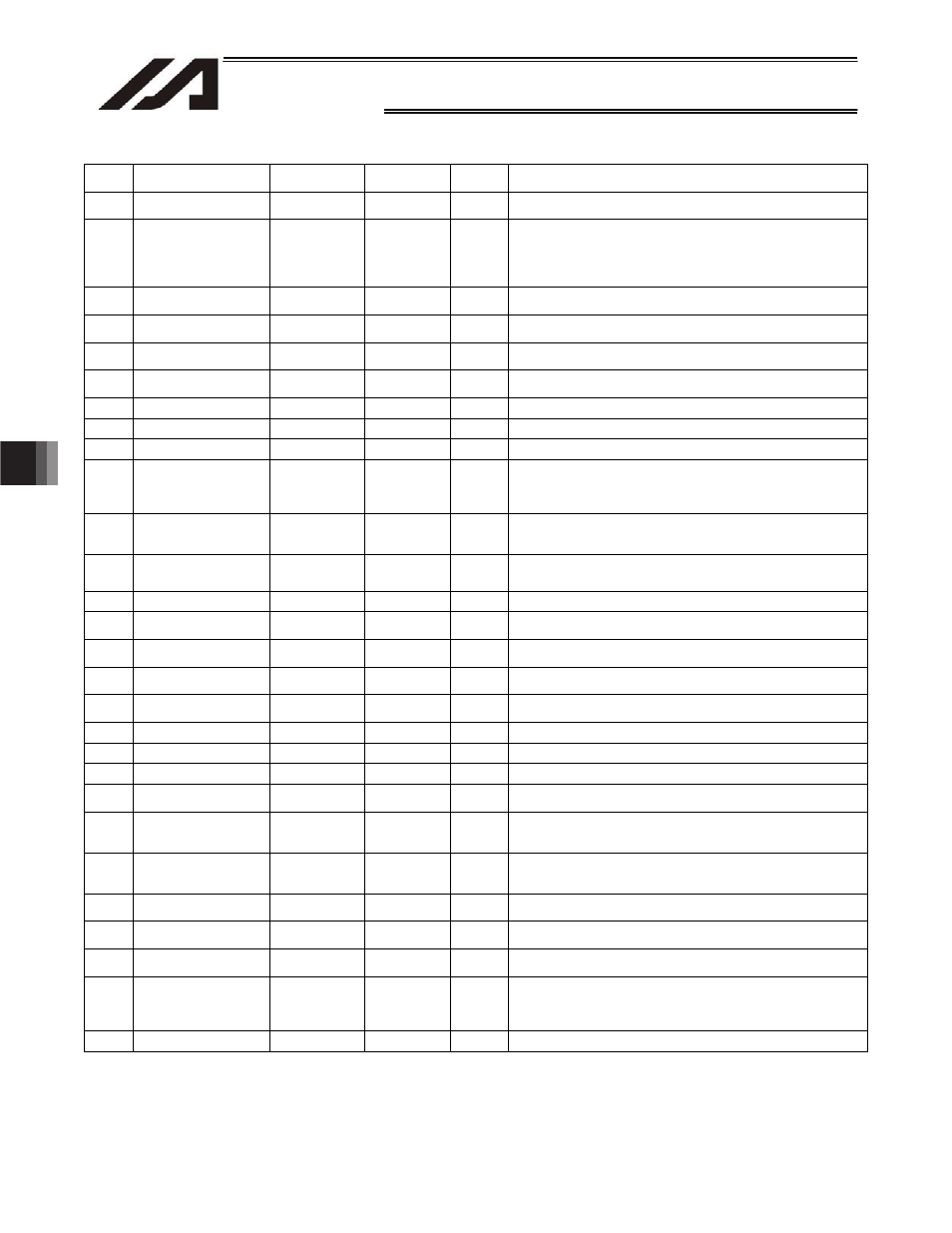

Axis-Specific Parameters

No Parameter

name

Default value

(Reference)

Input range

Unit

Remarks

31

Offset travel speed at

home return

3

1 to 500

mm/sec

32

Actual distance between

phase Z and end

0 -1

to

99999

0.001

mm

Absolute distance from the end (mechanical or LS). Obtained

automatically if the distance is a negative value. When multiple

actuators are combined, it is recommended to write the flash ROM

after automatic acquisition. (Refer to axis-specific parameter No.

76)

33 Ideal

distance

between

phase Z and end

0

0 to 99999

0.001

mm

Absolute distance from the end (mechanical or LS). (Refer to axis-

specific parameter No. 76)

34 Brake

equipment

specification

0

0 to 1

0: Not equipped, 1: Equipped

35

Brake unlock check time

10

0 to 3000

msec

Time after receiving a brake-unlock start response until transition to

an operation-enabled status

36

Brake lock check time

10

0 to 1000

msec

Time after receiving a brake-lock start response until start of servo

OFF

37

Change prohibited

0

0 to 1

0: Rotary encoder

38

Encoder ABS/INC type

0

0 to 1

0: INC, 1: ABS

39

Change prohibited

1

0 to 1

40 Pole-sense

initial

tryout

direction selection

(For future expansion =

Change prohibited)

0

0 to 1

0: Negative end of the coordinate system

1: Positive end of the coordinate system

41 Pole

sense

speed

(For future expansion =

Change prohibited)

25

1 to 100

DRVVR

42

Encoder resolution

800

0 to 99999999

Pulse/rev,

0.001

Pm/pulse

Pulses (before division)/rev, in the case of a rotary encoder

43

Encoder division ratio

0

-7 to 7

Pulses are multiplied by (“n”th power of 1/2).

44 Length

measurement

correction

0 -99999999

to

99999999

0.001

mm/1M

Valid only for linear movement axes. (Coordinates other than the

encoder reference Z point will change proportionally.)

45 to

46

(For expansion)

0

47

Screw lead

6000

1 to 99999999

0.001

mm

Valid only for linear movement axes.

48 to

49

(For expansion)

0

50

Gear ratio numerator

1

1 to 99999999

51

Gear ratio denominator

1

1 to 99999999

52 (For

expansion)

0

53

Setting bit pattern 1 of

each axis

0 0H

to

FFFFFFFFH

54

Travel distance for push

stop detection at home

return

20

1 to 99999

0.001

mm

Used to check the push motion during home return.

55

Travel distance for push

stop detection at

positioning

30

1 to 99999

0.001

mm

Used to check the push motion during PUSH command operation.

56 Push-abort

deviation

ratio at home return

5000

1 to 99999

Deviation is compared against “Steady-state deviation of push

speed + Push-speed pulse speed x Abort deviation ratio.”

57 Push-abort

deviation

ratio at positioning

5000

1 to 99999

Deviation is compared against “Steady-state deviation of push

speed + Push-speed pulse speed x Abort deviation ratio.”

58

Positioning band

100

1 to 9999

0.001

mm

59 Allowable

deviation

error ratio

(Maximum speed pulse

ratio)

300

1 to 9999

Deviation is compared against “Steady-state deviation of maximum

operating speed of each axis + Pulse speed of maximum operating

speed of each axis x Allowable deviation error ratio.”

60

Position gain

45

1 to 9999

/s