IAI America TT-C3 User Manual

Page 343

333

INTELLIGENT ACTUATOR

Appendix

Appendix

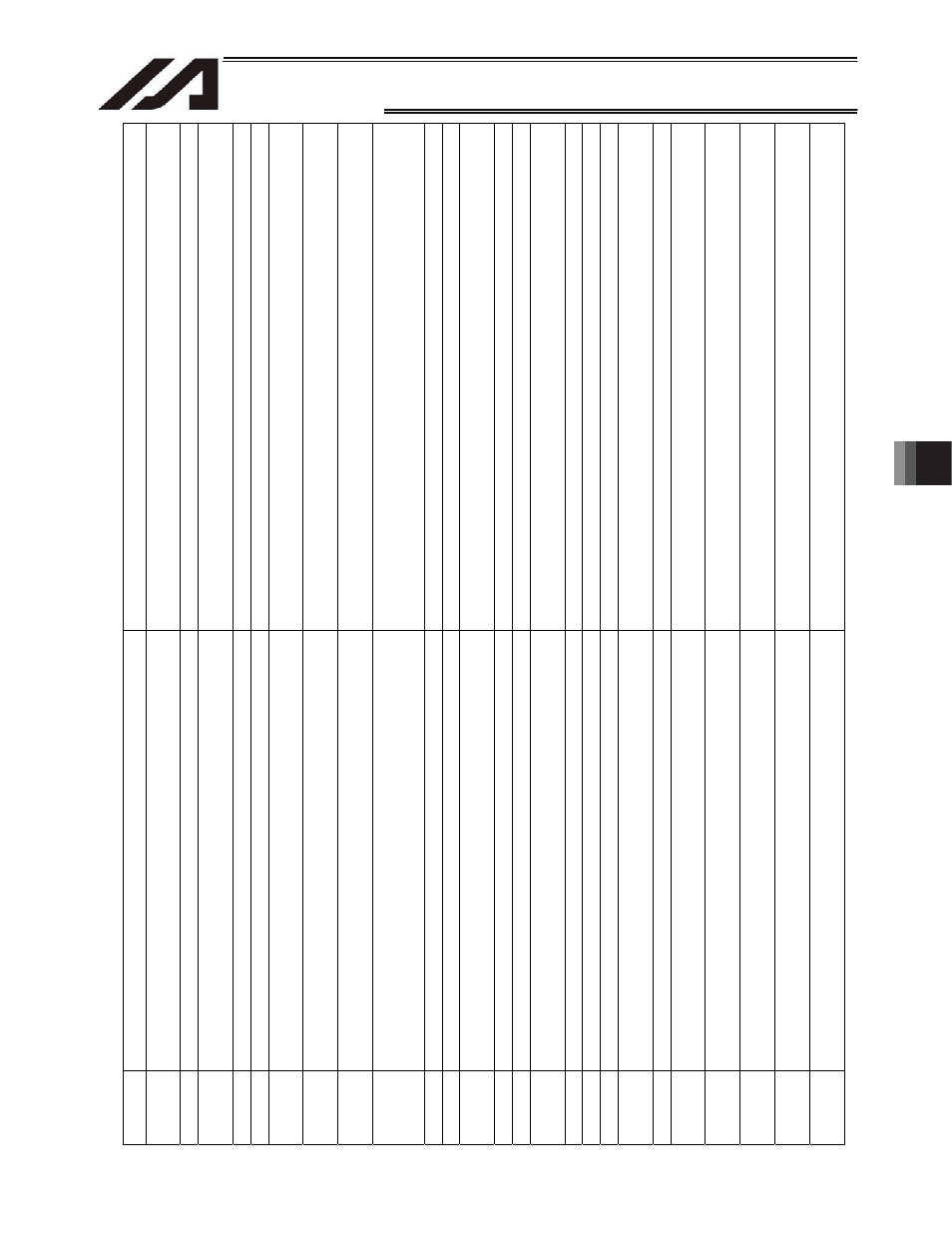

(In the panel windo

w

, the th

ree digits after “E” indicate a

n error numbe

r.)

Error No.

Error name

Description, a

c

tion, etc.

CB2

BGPA/

EDPA

pair-end mismatch error

The BGPA/EDPA s

y

nta

x

is invalid. EDPA

w

a

s declared

before BGPA,

or

another BGPA w

a

s declared

after BGPA

w

ithout first declaring EDPA.

CB4

Arch-motion Z-ax

is non-declaration error

Z-ax

is has not

been declared by PCHZ or ACHZ.

CB5

BGPA non-de

claration error during palletizing setting

Palletizing sett

ing cannot be

performed w

it

hout first declaring BGPA.

Declare BG

PA.

CB6

Palletizing point error

The palletizing

points are invalid (non-Z-ax

is components are absent, etc.).

CB7

Arch-trigger non-declaration error

Declare arch t

riggers using PTRG or ATRG.

CB8

No 3-point tea

ching setting e

rror at palletizing angle acqu

isition

The palletizing

angle cannot

be acquired until setting b

y palletizing

3-p

oint

teaching is co

mplete.

CB9

PX/

PY-a

xis in

determinable error at palletizing angle acq

uisition

Angle cannot

be calculated

because there are too many vali

d a

x

es in t

he 3-

point teaching

data and thus

PX/

PY-a

x

e

s c

annot be spec

ified.

CBA

Reference-axis/PY/

PY-axis

mismatch error at palletizing

angle

acquisition

Angle cannot

be calculated

because the reference axis

for angle calc

ulation

is neither of the ax

es

comprising the PX/PY-a

x

es as set

by 3-point teaching.

CBB

Reference-point/PX-a

x

is en

d-point duplic

ation error at palletizing

angle acquisition

Angle cannot

be calculated

because the reference point of 3-point teaching

is the same as

the PX-a

x

is e

nd-point data other than the PZ-ax

is

component and thus arc tangent cannot b

e calculated.

CBC

Palletiz

ing mo

tion calculatio

n error

Trapezoid control calculation

error for palletizing motion

CBD

MOD command divisor 0 error

“0” w

as specified as the divisor in the MOD command.

CBE

Target-locus boundary over error

The target position or movement locus e

xceeded the po

sitioning boun

dary

in the infinite-stroke mode.

CBF

Positionin

g dis

tance overflo

w error

The positionin

g distance is t

oo large.

CC0

Ax

is mode err

or

The ax

is mod

e is invalid.

CC1

Speed change

condition error

An attempt

w

a

s made to change the speed

of an axis

w

h

ose speed ca

nnot

be changed (ax

is operating in S-motion, et

c.).

CC2

Driver parameter list number error

The

driver parameter list number is invalid

.

CC3

Angle error

The angle is invalid.

CC4

SEL data erro

r

The SEL data

is invalid.

CC5

Positionin

g bo

undary pull-out error

An attempt

w

a

s made to ex

e

c

ute a command not permitted outside the

positioning bo

undary.

CC6

Driver error pri

mary detection

A driver error w

a

s found by

primary detection.

CC7

Palletiz

ing mo

vement PZ-axis pattern non-detection error

PZ-ax

is comp

onent is not fo

und in the a

x

is

pattern during palletiz

ing

movement.

CC8

Arch top Z-ax

is pattern non-detection error

Z-ax

is compo

nent relating to the highest

point of arch motion is not f

ound in

the ax

is pattern during arch motion operation.

CC9

Arch trigger Z-ax

is pattern n

on-detection error

Z-ax

is compo

nent relating to arch motion is not found in

the ax

is patte

rn o

f

the arch-trigger declaration point data.

CCA

Arch top/end-

point reversing error

The coordinates of highest

point and end

point are reversed during arch

motion operation.

CCB

Arch start-point/trigger reversing error

The coordinates of start point and start-point arch trigger are reversed

during arch motion operation.