Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 796

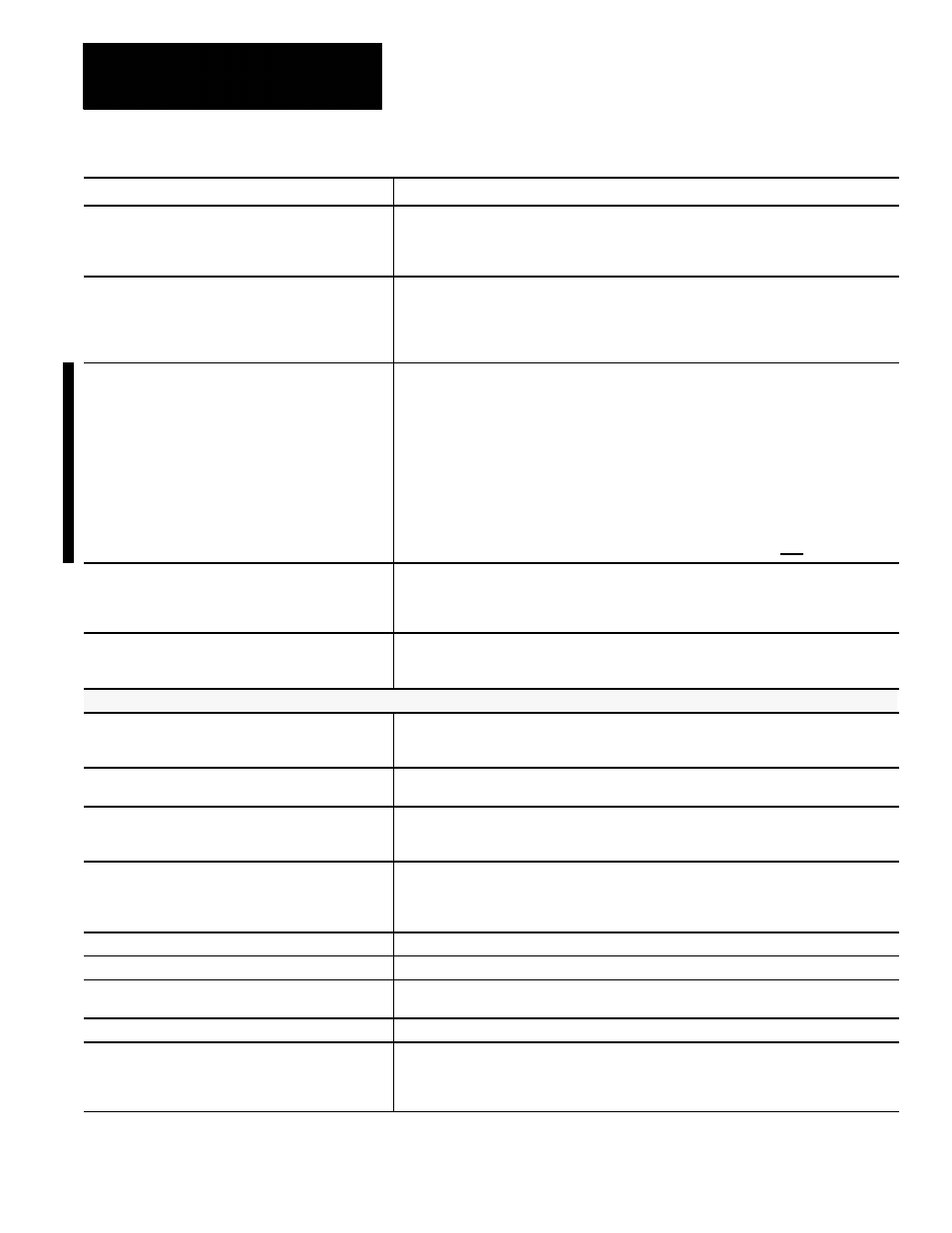

Error and System Messages

Appendix B

B-42

Message

Description

SYSTEM MODULE GROUND FAULT

The 1394 system module has detected a ground fault. The system generates a ground fault

when there is an imbalance in the DC bus of greater than 5A. This drive error can be caused by

incorrect wiring (verify motor and ground wiring), motor malfunction, or an axis module IGBT

malfunction.

SYSTEM MODULE OVER TEMP

The 1394 contains a thermal sensor which senses the internal ambient temperature. Causes

could be: that the cabinet ambient temperature is above rating. The machine duty cycle

requires an RMS current exceeding the continuous rating of the controller. The airflow access to

the 1394 is limited or blocked. This does not necessarily indicate a motor over temperature.

Motor over temperture sensors should be wired directly into the E-Stop string.

SYSTEM MODULE OVER VOLTAGE

The 1394 system module buss voltage exceeds the maximum operating voltage. The dc power

bus is continuously monitored. If it exceeds a preset level (810V dc), a fault is sensed and the

power supply is disabled. There are several possible causes for this error.

•

an undersized shunt requirement

•a blown shunt regulator fuse

•a malfunctioning shunt regulator transistor

•the power driver board is malfunctioning and incorrectly sensing the bus voltage

•an incorrectly set CNC acc/dec rate

•an excessive input line voltage

•the system inertia is too high causing excessive energy to be returned to the power supply bus

•a vertical axis with insufficient counterbalancing is overdriving the servomotor and causing excessive

energy to be returned to the power supply bus

•an incorrect power supply is installed in your system. Make sure you are using a CNC power supply

SYSTEM MODULE PHASE LOSS

The 1394 system module has detected a loss of one of the input power phases. The

three--phase input line is monitored and a fault will be issued when a phase loss is detected.

Typical causes include, one or more input line fuses have opened, contactor malfunction, or

incorrect wiring.

SYSTEM MODULE UNDER VOLTAGE

The 1394 system module voltage does not meet the minimum operating voltage. The DC power

buss shall activate the under voltage limit when the bus drops to 275 VDC or less. It will clear at

300 Vdc. Typical causes include low voltage on the three phase input.

T

(T) WORD IN CIRCULAR MODE

An attempt was made to activate a tool length offset in a block that generates a circular move.

Tool length offsets can be activated only in linear blocks (or in non-motion blocks if AMP is so

configured).

T--WORD NOT ALLOWED WITH M06

NEXT TOOL IN T WORD was selected as the tool--change type in AMP while a T--word is

programmed in an M06 block.

TAN CIRCLE NOT IN 1ST BLOCK

When editing a program, an attempt was made to digitize an arc using {CIRCLE TANGNT} as

the first block in the program. To use this digitizing format, the control must first have a tool path

programmed to make the arc tangent.

TEMPLATE PROGRAM NOT FOUND

A transfer line quick view item was selected without the correct part program template present in

the protected directory. There are 19 transfer line cycles and there must be part program

templates QV01 thru QV19 present in the protected directory. Refer to your T-LINE-9 Quick

Start guide for details on replacing/restoring these part program templates.

THIRD SPINDLE NOT AVAILABLE

AMP configuration error; spindle 3 can be configured only on a 9/290.

THIRD SPINDLE NOT CONFIGURED

For spindle 3 to be programmable, it must be configured in AMP; a decode error.

THRDS/IN WORD FORMAT FINER THAN

The word format programmed is requesting a finer resolution than the axis word format for the

corresponding axis allows. These word formats are set in AMP.

THREAD FEEDRATE TOO LARGE

The lead is too large in threading mode. Program slower spindle speed.

THREAD LEAD ERROR

The thread lead was too large or too small. This commonly occurs when cutting a variable

thread lead and before the end of the threading pass is reached. Either the lead goes to zero

for a decreasing lead thread, or an axis speed would exceed its maximum allowable cutting

feedrate when cutting an increasing lead thread.