Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 607

Cylindrical Grinding Fixed Cycles

Chapter 17

17-33

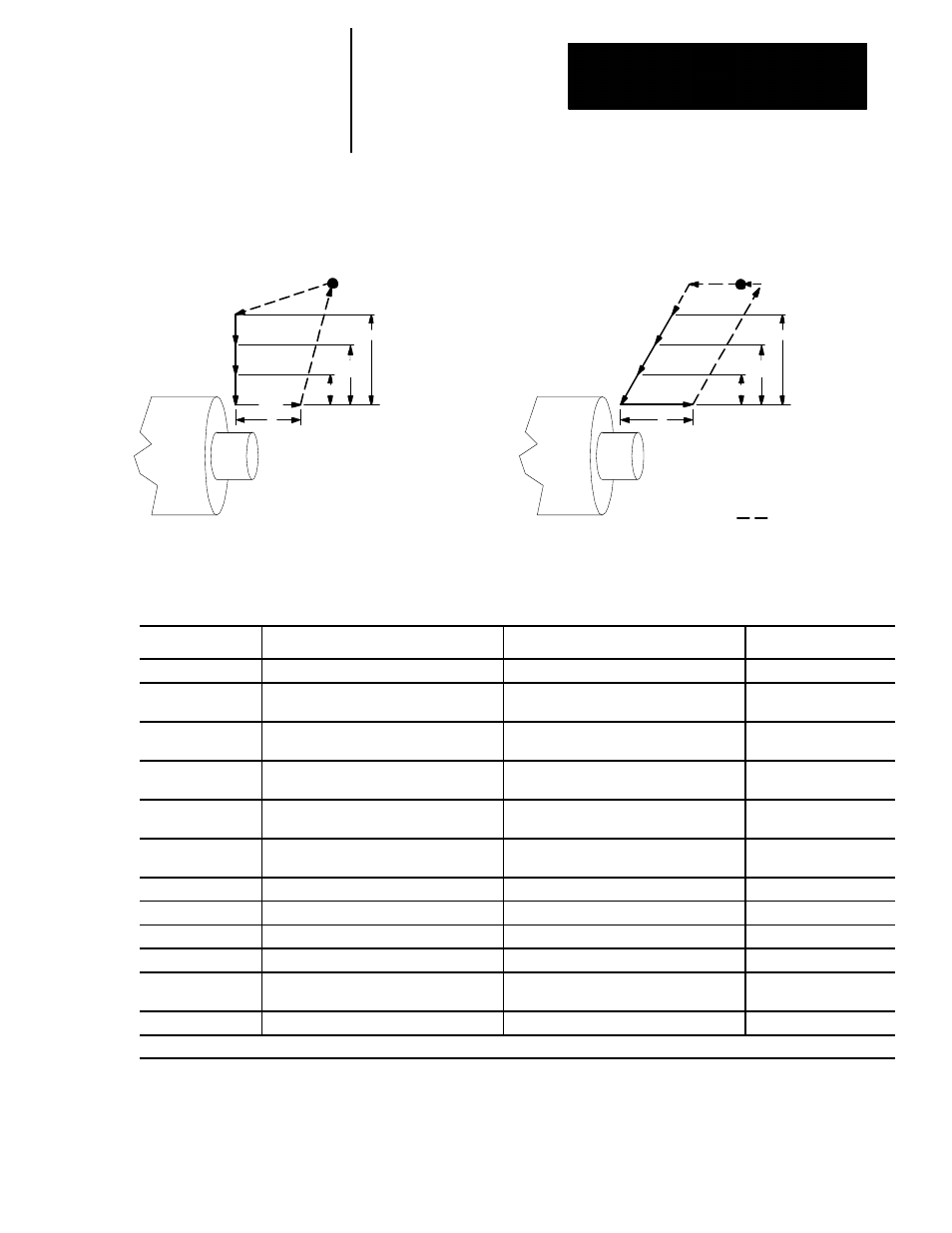

Figure 17.10

G89 Multi-Step Plunge with Blend

Part

@F

@E

@,F

@,E

R

I

Q

Rapid Moves

K

Start Point

Part

@F

@E

@,F

@,E

R

I

Q

K

Start Point

Angled-Wheel Grinders in Two Step Grinding Mode (G16.4)

Non-Angled Wheel Grinders or

Angled-Wheel Grinders in Normal Grinding Mode (G16.3) or

G15 Mode in Selected Plane

Table 17.I

G89 Cycle Parameters

Parameter:

Definition:

Default Value:

Possible Value:

X

1

(plane axis 1)

plunge end point

value must be programmed

abs. or inc.

Z

1

(plane axis 2)

shoulder end point

modal while in cycle/value must be

programmed

abs. or inc.

R

3

clearance plane

modal while in cycle/zero if not programmed

incremental, unsigned,

radius or diameter value

I

3

medium plunge distance

modal while in cycle/zero if not programmed

incremental, unsigned,

radius or diameter value

Q

3

fine plunge distance

modal while in cycle/zero if not programmed

incremental, unsigned,

radius or diameter value

K

2 3

blend distance

modal while in cycle/zero if not programmed

incremental, signed,

radius or diameter value

F

2

coarse plunge feedrate

last feedrate programmed

valid F word

E

3

medium plunge feedrate

modal while in cycle/zero if not programmed

valid F word

,F

3

fine and micro-feed feedrate

modal while in cycle/zero if not programmed

valid F word

,E

3

blend feedrate

modal while in cycle/zero if not programmed

valid F word

L

3

number of spark-out revolutions in IPR

mode, seconds in IPM mode, or V/D mode

must be programmed

integer from zero to 999

P

3 for G89 2 for G89.1

dress program number

from last cycle programmed

valid program number

1

must be programmed

2

must have been programmed in some previous block if omitted

3

optional