Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 715

In-process Dresser

Chapter 21

21-9

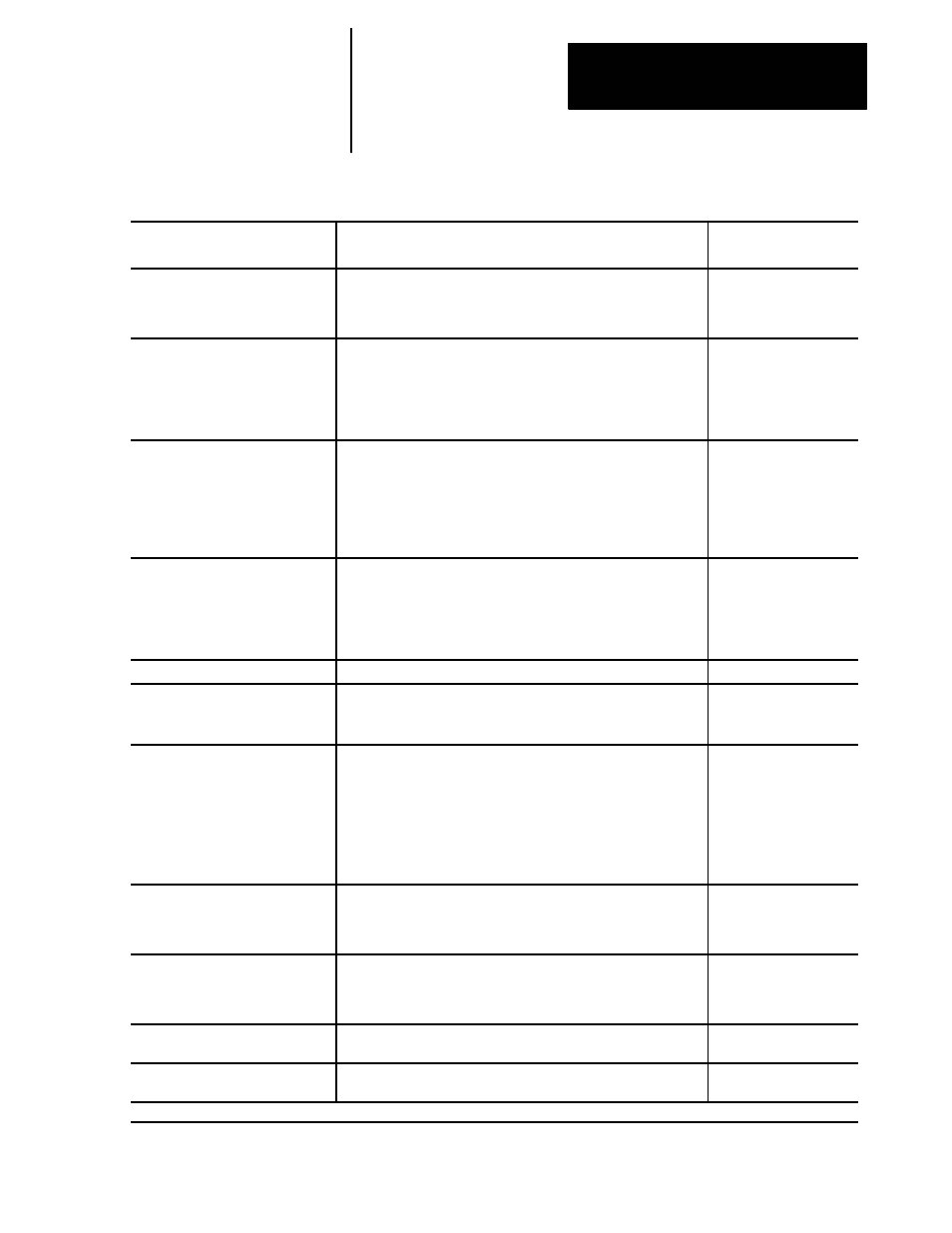

Table 21.A

Dresser Parameters on the In-process Dresser Screen

This Parameter:

(paramacro system parameter)

Indicates:

Range:

DRESSER/ACTIVE/INACTIVE

if the in-process dresser is currently active (turned on) or inactive

(turned off). This is controlled by PAL.

Active

(in-process dresser on)

Inactive

(in-process dresser off)

DRESSER HOLD/NOT HOLD

if the in-process dresser is currently in the hold state. The hold state

stops the wheel dressing operation without turning off the in-process

dresser. Although both dress retract and dress retract return are

available, programmed and jog moves on the dressing axis are still

not permitted because the in-process dresser is still active. This is

controlled by PAL.

Hold

(dressing infeed stopped)

Not Hold

(dressing in-process)

INITIAL WHEEL DIAMETER

the starting wheel diameter that was active the last time the in-process

dresser was calibrated. When the wheel is calibrated, the control

writes the value of the new wheel diameter into this parameter. The

difference between this parameter and the “Current Wheel Diameter”

parameter is equal to the amount the wheel has been dressed since it

was last calibrated. The value of this parameter only changes when

the wheel is calibrated or the in-process dresser is deactivated.

0 to 9999.9999 [inch]

0 to 99999.999 [mm]

CURRENT WHEEL DIAMETER

(paramacro #5508)

the value of the current wheel diameter. When the wheel is calibrated,

the control copies the “New Wheel Diameter” value into this

parameter. Once the in-process dresser is enabled, this value is

reduced by the amount of wheel shrinkage as the wheel is dressed.

When the in-process dresser is disabled, the control copies the current

wheel diameter value into the “Initial Wheel Diameter” parameter.

0 to 9999.9999 [inch]

0 to 99999.999 [mm]

CURRENT DRESSER RPM

the current speed of the rotating roll dresser in RPM.

System Defined

* NEW WHEEL DIAMETER

(paramacro #5500)

the value of the wheel diameter before the in-process dresser is

calibrated. Once calibrated the value of this parameter is copied into

the “Initial Wheel Diameter” parameter.

0 to 9999.9999 [inch]

0 to 99999.999 [mm]

* WARNING WHEEL DIAMETER

(paramacro #5501)

a wheel diameter greater than the “Minimum Wheel Diameter”. When

the wheel is dressed down to this diameter, a warning message is

displayed. This value should be large enough so that the operator has

sufficient wheel left to finish current operations and take corrective

action before the wheel is dressed down to the “Minimum Wheel

Diameter”. Your system installer determines in PAL the control’s

response to a wheel that has been dressed down to the warning

wheel diameter.

0 to 9999.9999 [inch]

0 to 99999.999 [mm]

* MINIMUM WHEEL DIAMETER

(paramacro #5502)

the minimum acceptable wheel diameter. When the wheel is dressed

down to this diameter, a warning message is displayed. The system

installer determines in PAL the control’s response to a wheel that has

been dressed down to the minimum wheel diameter.

0 to 9999.9999 [inch]

0 to 99999.999 [mm]

* MAXIMUM WHEEL SPEED(RPM)

(paramacro #5503)

the maximum speed of the grinding wheel. This is the maximum

speed the grinding wheel is allowed to reach when constant surface

speed is turned on. On cylindrical grinders keep in mind that only one

spindle is controlled by CSS.

0 to 999999. (RPM)

* WHEEL WIDTH

(paramacro #5509)

this parameter is present only on this screen for operator convenience

in entering this parameter for later use with paramacros.

0 to 9999.9999 [inch]

0 to 99999.999 [mm]

* DRESSER ROLL DIAMETER

(paramacro #5504)

the diameter of the roll dressing tool.

0 to 9999.9999 [inch]

0 to 99999.999 [mm]

* This parameter can be configured by the operator on this screen. Other parameters are assigned by the control or PAL during calibration or dressing.