1 machine (absolute) coordinate system – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 318

Coordinate Control

Chapter 11

11-2

The control has two types of coordinate systems:

machine coordinate system. This is often referred to as the absolute

coordinate system, which is unique to the individual grinding machine

work coordinate system. This is defined based on the coordinate

system used in the part drawing of a part to be ground by the machine

Programs are usually written based on the work coordinate system.

The machine coordinate system is the basic coordinate system set for every

CNC grinder. It is established after completion of the machine homing

operation. It cannot be offset or shifted in any way. Its position is

determined in AMP by your system installer.

Important: You must home the machine before you can activate any

coordinate system. The homing operation refers to the positioning of the

axes to a machine-dependent fixed position, which is called the machine

home. For more on machine homing, see page 4-11.

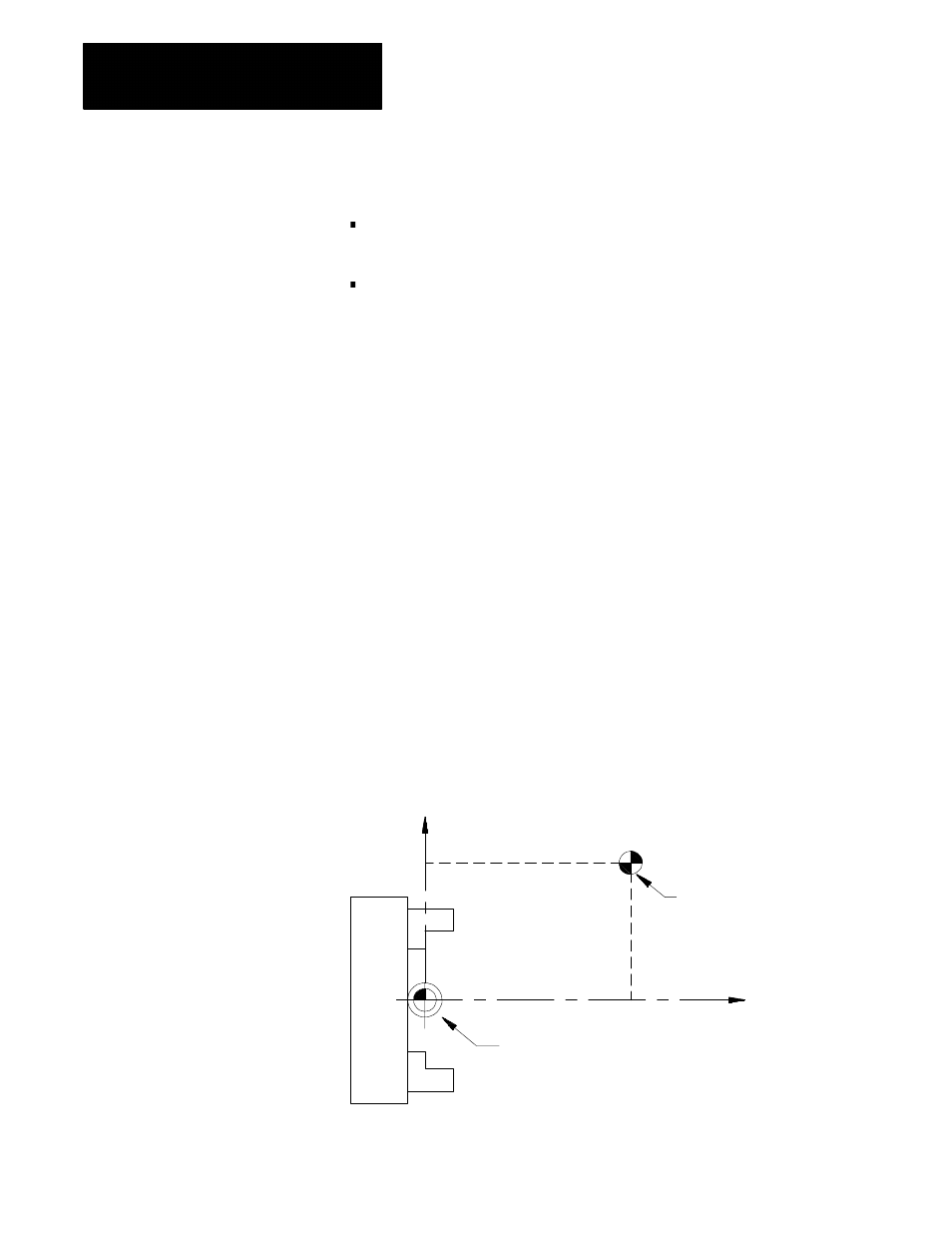

The zero point of the machine coordinate system is referenced from the

machine home point. This is done by assigning a coordinated location to

the machine home point. The home position for each axis can be given

any legal coordinates such as 15.00, -20.0000, or -2.256.

Once established, the machine coordinate system is not affected by a

control reset operation or any other programming or operator operation.

Figure 11.1

Machine Coordinate System, Home Coordinate Assignment

Chuck

Machine Coordinate System

zero point

+Z

+X

Mechanically fixed

Machine Home

point

15

10

12168-I

11.1

Machine (Absolute)

Coordinate System