Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 48

Chapter 2

Operating the Control

2-28

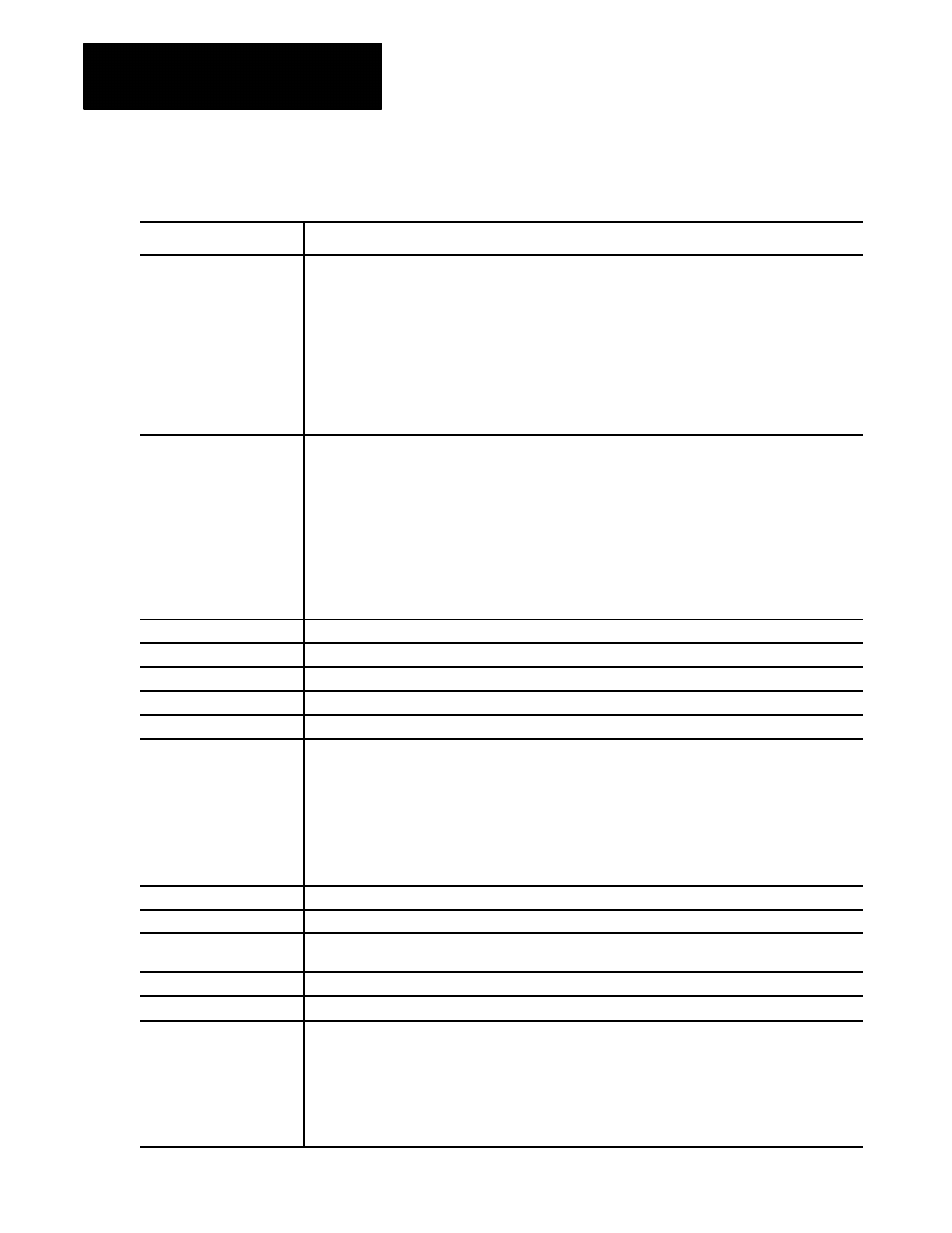

Table 2.C

Password Protectable Functions

Parameter Name

Function becomes accessible when parameter name appears in reverse video:

1) ACTIVE PROGRAM

To access these features, both ACTIVE PROGRAM and PROGRAM MANAGE (number 2 below) must be

assigned to the user.

• {SELECT PRGRAM} — Select a program for automatic operation.

• {SEARCH} — Search a part program for a character string or sequence number to begin program

execution at.

• {MID ST PRGRAM} — Start program execution from some location other than the beginning and

still set all of the parameters previously defined in the program active.

• {T PATH GRAPH} — Enable the active graphics feature.

• {CANCEL PRGRAM} — Disable the currently active program from execution.

• {SEQ STOP} — Choose a sequence number for automatic program execution to stop at.

2) PROGRAM MANAGE

• {ACTIVE PRGRAM} — All of the functions in 1 above provided ACTIVE PROGRAM (number 1

above) is also selected.

• {EDIT PRGRAM} — Edit an existing program or create a new program.

• {DISPLY PRGRAM} — Display a program using the display function.

• {COPY PRGRAM} — Copy a program to or from memory.

• {VERIFY PRGRAM} — Verify that two programs are identical using the verify function.

• {COMENT} — Add comments to a program name in the directory.

• {RENAME PRGRAM} — Change a program name.

• {DELETE PRGRAM} — Delete a single program stored in memory.

• {REFORM MEMORY} — Delete all programs currently stored in memory.

3) EDIT PROGRAM

{EDIT PRGRAM} — Edit an existing program or create a new program.

4) COPY PROGRAM

{COPY PRGRAM} — Copy a program to or from memory or storage device.

5) RENAME PROGRAM

{RENAME PRGRAM} — Rename a program name.

6) DELETE PROGRAM

{DELETE PRGRAM} — Delete a single program stored in memory.

7) REFORM MEMORY

{REFORM MEMORY} — Delete all programs currently stored in memory and format RAM.

8) OFFSETS

• {WORK CO-ORD} — Display and alter the preset work coordinate system zero locations and the fixture

offset value.

• {WHEEL GEOMET} — Display and alter the wheel geometry tables.

• {RADIUS TABLE} — Display and alter the dresser/wheel radius and orientations.

• {ACTIVE OFFSET} — Change the currently active offset number without requiring the programming of a

different offset number.

• {COORD ROTATE} — Rotate all of the work coordinate systems from the machine coordinate system.

• {BACKUP OFFSET} — Make a copy of the current tool offset data.

9) RADIUS TABLE

10) WHEEL GEOMETRY

{WHEEL GEOMET} — Display and alter the wheel geometry, radius and orientation values.

11) ACTIVE OFFSET

{ACTIVE OFFSET} — Change the currently active offset number without requiring the programming of a

different offset number.

12) BACKUP OFFSET

{BACKUP OFFSET} — Make a copy of the current wheel offset data.

13) QUICK CHECK

™

{QUICK CHECK} — Use the syntax and format checker or the {QUICK CHECK} with graphics function.

14) SYSTEM SUPORT

• {PRGRAM PARAM} — Display and change the tables for programmable zones 1 and 2, the single digit

feedrates, and the fixed cycle operating parameters.

• {AMP} — Change any of the online AMP features.

• {DEVICE SETUP} — Display and change any of the communication parameters for the peripheral

devices.

• {MONI-TOR} — Display the current I/O configurations and the axis monitor for following error, distance

to marker, etc.