Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 661

Paramacros

Chapter 20

20-17

5500 to 5509

In-Process Dresser Parameters

20-32

5600 to 5625

Part Program Block Create through PAL Display Pages

20-33

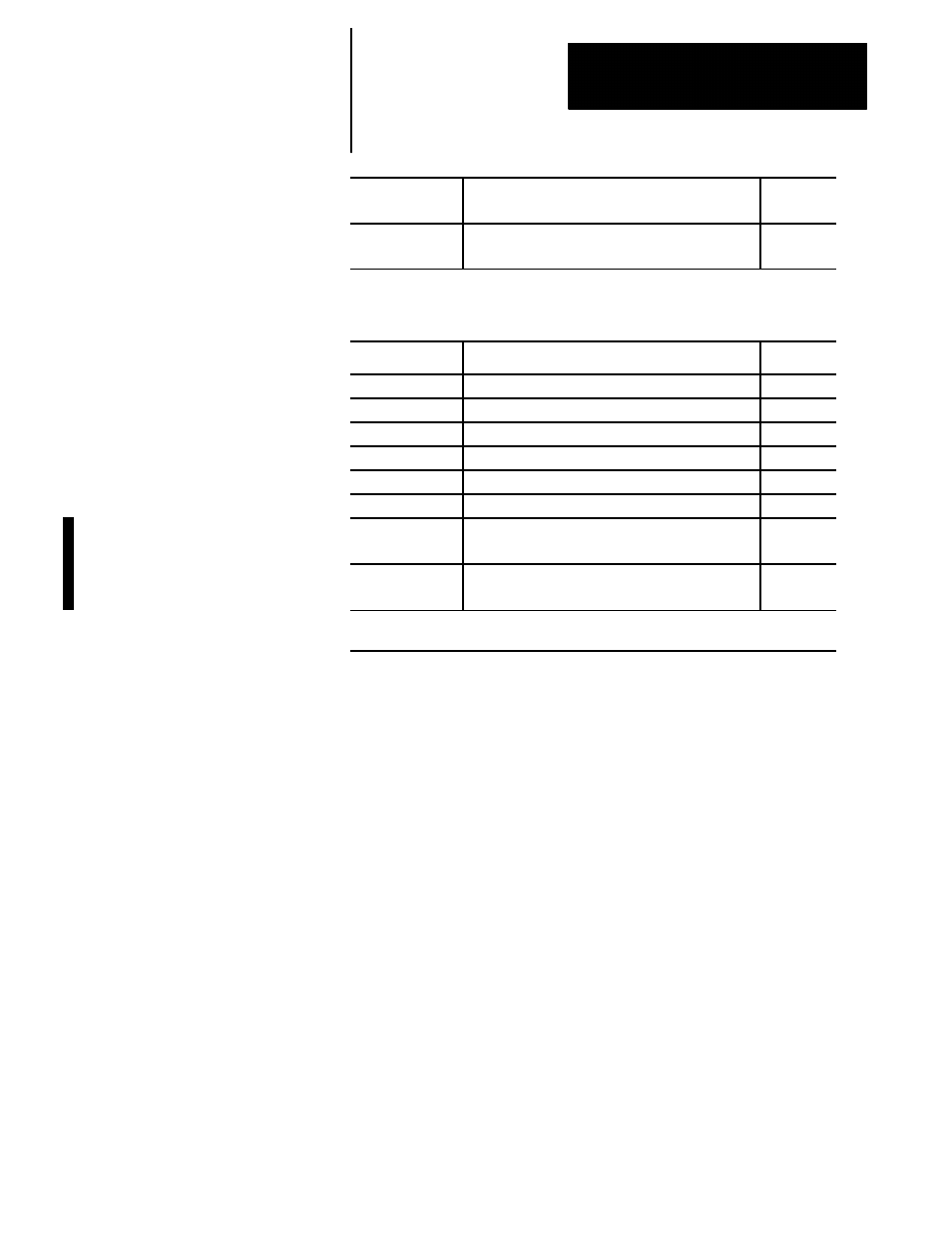

Table 20.D

System Parameters (continued)

Parameter #

System Parameter

Page

5630

1

S--Curve Time per Block

20-33

5661 to 5642

1

Acceleration Ramps for Linear Acc/Dec Mode

20-34

5651 to 5662

1

Deceleration Ramps for Linear Acc/Dec Mode

20-34

5671 to 5682

1

Acceleration Ramps for S--Curve Acc/Dec Mode

20-35

5691 to 5702

1

Deceleration Ramps for S--Curve Acc/Dec Mode

20-35

5711 to 5722

1

Jerk

20-36

5731 to 5743

Home Marker Distance

20-36

5751 to 5763

Home Marker Tolerance

20-37

1

These parameters may only have their value received (read-only)

2

These parameters may only have their value changed (write-only)

Pages 20-18 through 20-33 contain descriptions of the system variables.

Important: Angled wheel grinders that have a virtual axis can access

system parameters for the virtual axis. The virtual axis is the non-physical

axis created by the control that is perpendicular to the part spindle

centerline. This virtual axis is assigned system paramacro parameters as

the last axis number after the last real axis (excluding non-positioning

spindles). For example if your angled wheel grinder has two linear axes, a

rotary axis that controls the wheel angle, a non positioning part spindle,

and a wheel spindle, then system parameters for axis four represent the

status of the virtual axis.