5 precautions on corner grinding – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 441

Axis Motion

Chapter 12

12-69

When exponential acc/dec is active, the control automatically performs

acc/dec to give a smooth acceleration/deceleration for grinding wheel

motion. However, there are cases in which exponential acc/dec can result

in rounded corners on a part during grinding.

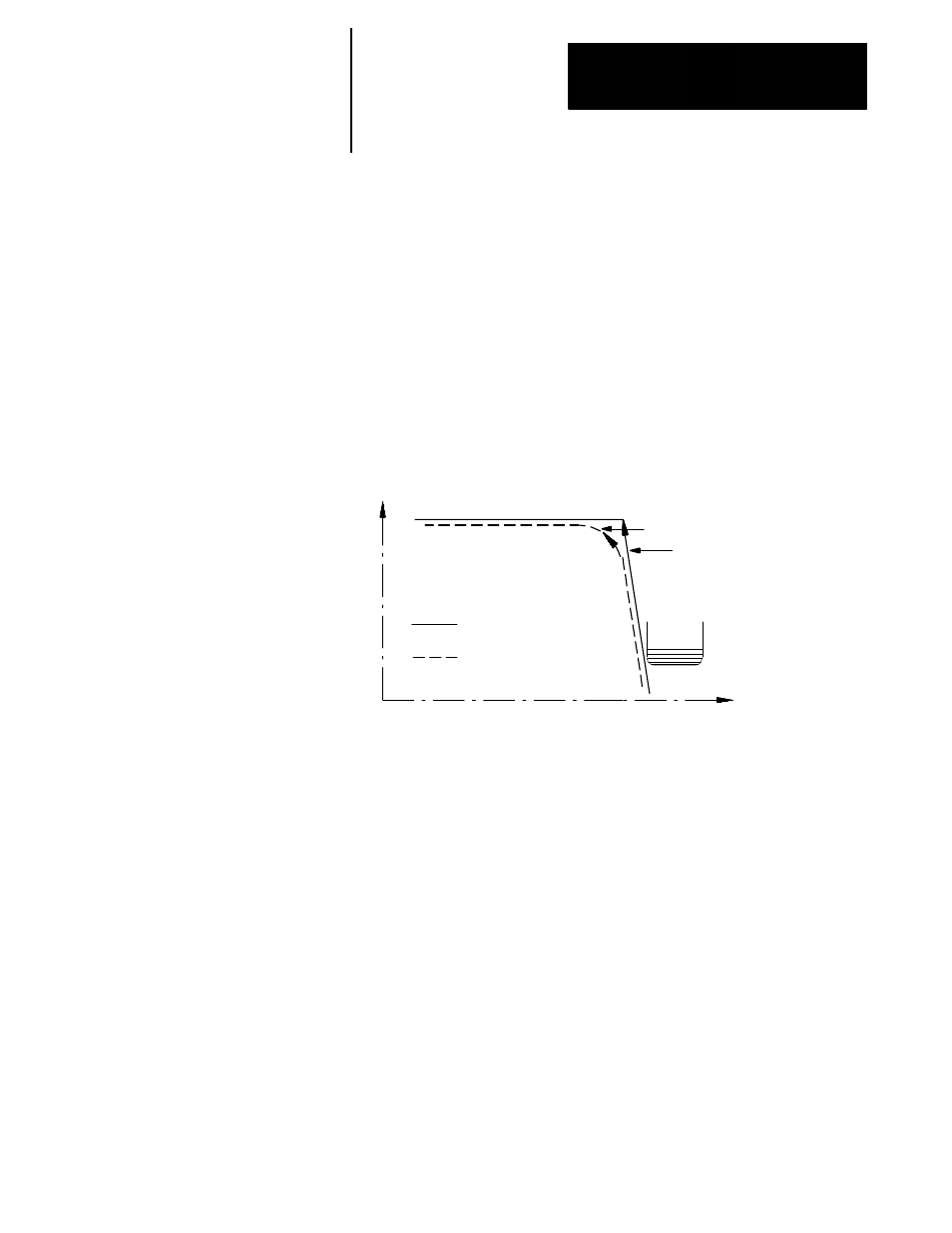

As illustrated in Figure 12.34, this problem is most obvious when the

direction of grinding changes from the X-axis to the Z-axis. In this case,

the X-axis is moving at nearly the full grinding feedrate while the Z-axis is

moving very slowly. The X-axis decelerates as it completes its move and

as soon as it reaches the AMP defined in-position band, the Z-axis begins

accelerating to make its commanded move. Since the Z-axis begins

motion before the X-axis finishes, a slight rounding results.

Figure 12.34

Rounding of Corners

Programmed wheel path

Actual wheel path

Z

X

Grinding

wheel

12041-I

G09, G61

G64

Use the following G--codes to eliminate corner rounding:

Exact Stop (G09 - - non-modal)

If a programmed motion block includes a G09, the axes move to the

commanded position and decelerate to zero speed; the control waits until

the following error for each of the programmed axes is within the AMPed

in-position band before completing the current block.

The G09 can be programmed in rapid (G00), feedrate (G01), or circular

(G02/G03) motion blocks, but is active only for the block in which it is

programmed.

Exact Stop Mode (G61 - - modal)

G61 establishes the exact stop mode. It is the modal equivalent of G09.

12.9.5

Precautions on Corner

Grinding