Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 443

Axis Motion

Chapter 12

12-71

corner override distance (DFC) -- vector distance from end of current

move (b) to point on programmed path (c) where corner override is

deactivated

corner override percent -- amount that feedrate is to be reduced once

corner override is activated

To use an exact stop function while the automatic corner override mode

(G62) is active, use the G09 instead of the G61. This is because G61 and

G62 belong to the same G modal group and cancel each other if

programmed. Be aware that G09 is non-modal.

Your system installer can change the rate in which a spindle is accelerated.

AMP allows the option of setting RAMP to occur in 2 ms intervals during

one system scan or as an immediate step. By writing the appropriate PAL

your system installer can also, in effect, generate a spindle “ramp” for even

smoother spindle acceleration. Refer to documentation prepared by your

system installer.

Use the G12 code to program the active controlling spindle for all

programmed axes motions for features and modes requiring spindle

operation. The G12 code is modal as only one spindle can be the

controlling spindle.

G12.1 — Spindle 1 Controlling

G12.2 — Spindle 2 Controlling

G12.3 — Spindle 3 Controlling

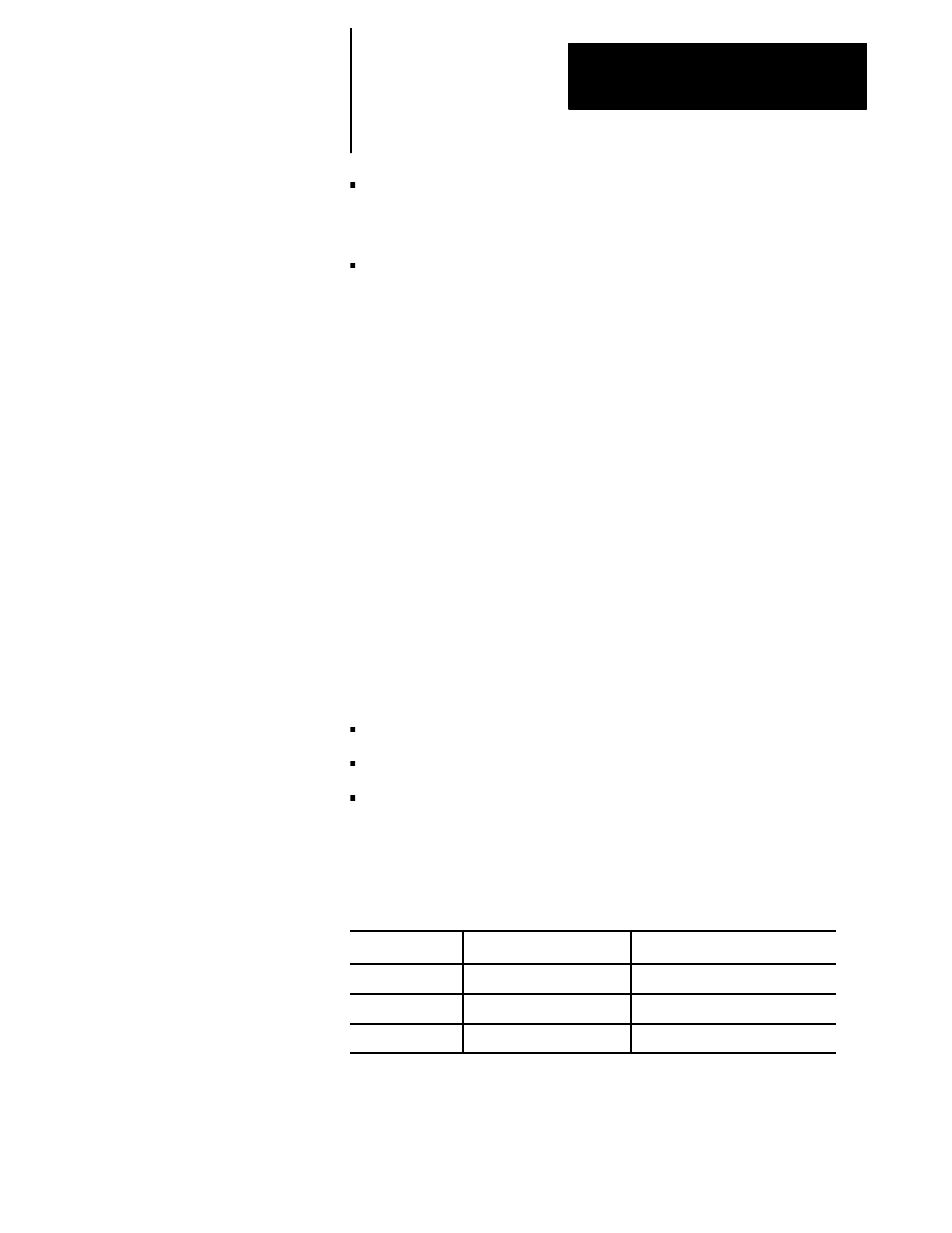

Table 12.C lists the allowed spindle capabilities.

Table 12.C

Spindle Capabilities

Control Type

Number of Spindles

Spindle Type

9/240

1

Spindle 1

9/260

2

Spindle 1, Spindle 2

9/290

3

Spindle 1, Spindle 2, Spindle 3

Spindle 1, as well as spindles 2 and 3, must be configured in AMP, and the

associated spindle parameters must be set properly to provide for the

required spindle functions.

12.9.6

Spindle Acceleration (Ramp)

12.9.7

Controlling Spindles

(G12.1, G12.2, G12.3)