Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 304

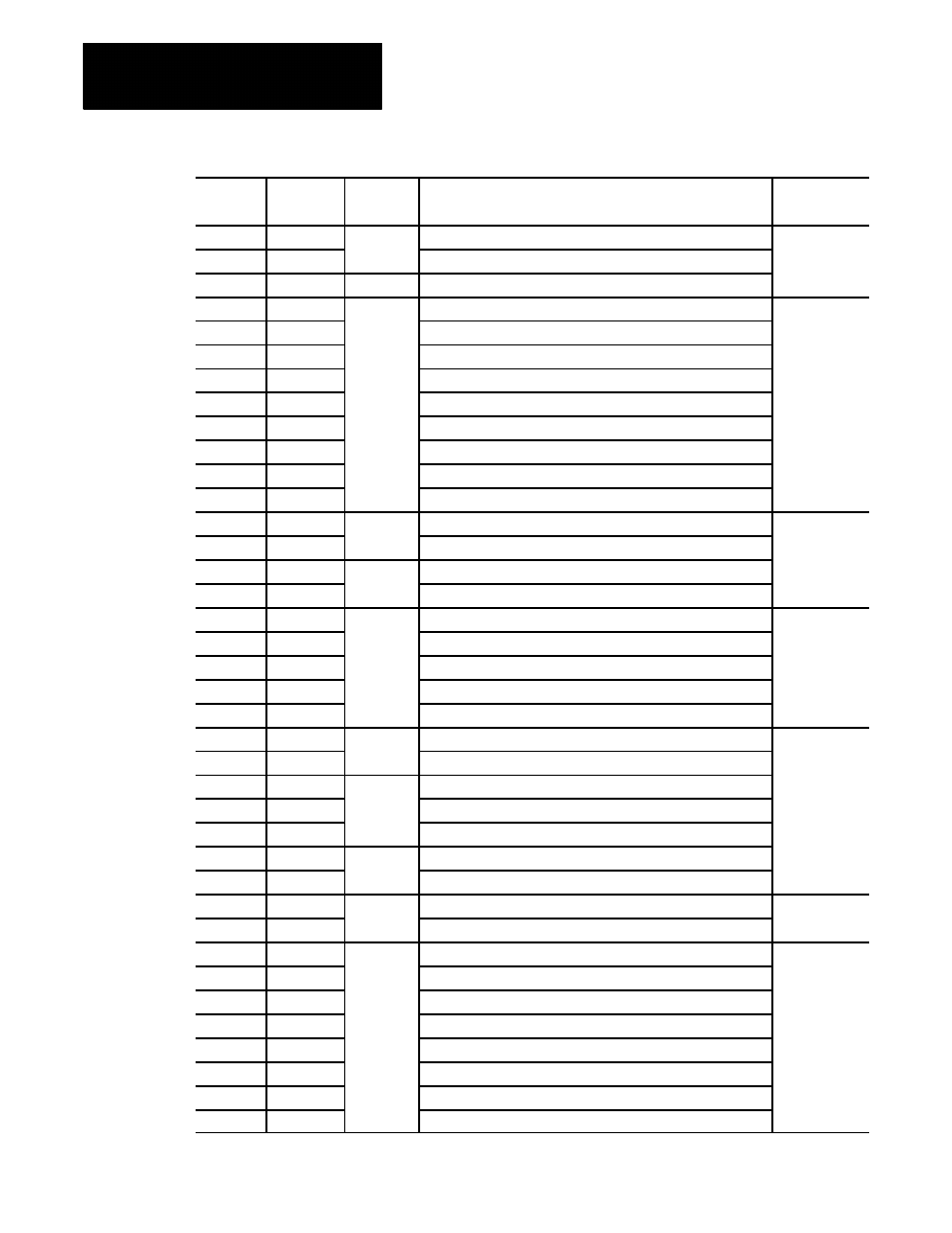

Introduction to Programming

Chapter 10

10-26

Surface

Grinder

Modal or

Non-modal

Function

Group

Number

Cylindrical

Grinder

G23

G23

04

Programmable Zone 2 and 3 (Off)

Modal

G23.1

G23.1

Programmable Zone

G24

G24

01

Single pass rough facing cycle

G27

G27

00

Machine home return check

Non-modal

G28

G28

Automatic return to machine home

G29

G29

Automatic return from machine home

G30

G30

Return to secondary home

G31

G31

External skip function 1

G31.1

G31.1

External skip function 1

G31.2

G31.2

External skip function 2

G31.3

G31.3

External skip function 3

G31.4

G31.4

External skip function 4

G33

G33

01

Constant lead thread grinding

Modal

G34

G34

Variable lead thread grinding

G36

G36

22

Short block Acc/Dec clamp enable

G36.1

G36.1

Short block Acc/Dec clamp disable

G37

G37

00

Tool gauging skip function # 1

Non-modal

G37.1

G37.1

Tool gauging skip function # 1

G37.2

G37.2

Tool gauging skip function # 2

G37.3

G37.3

Tool gauging skip function # 3

G37.4

G37.4

Tool gauging skip function # 4

G39

G39

20

Dresser/Wheel compensation (linear gen. blocks)

Modal

G39.1

G39.1

Dresser/Wheel radius compensation (circular gen. blocks)

G40

G40

07

Dresser/Wheel radius compensation cancel

G41

G41

Dresser/Wheel radius compensation, left

G42

G42

Dresser/Wheel radius compensation, right

G50.1

G50.1

11

Programmable mirror image cancel

G51.1

G51.1

Programmable mirror image

G52

G52

00

Offset coordinate system zero point

Non-modal

G53

G53

Motion in Machine coordinate system

G54

G54

12

Preset Work Coordinate System 1

Modal

G55

G55

Preset Work Coordinate System 2

G56

G56

Preset Work Coordinate System 3

G57

G57

Preset Work Coordinate System 4

G58

G58

Preset Work Coordinate System 5

G59

G59

Preset Work Coordinate System 6

G59.1

G59.1

Preset Work Coordinate System 7

G59.2

G59.2

Preset Work Coordinate System 8