Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 566

Surface Grinding Fixed Cycles

Chapter 16

16-16

Important: It is the programmer’s responsibility to make sure that

the reciprocation moves extend beyond the part sufficiently such that

the plunge move can be completed before the wheel comes back in

contact with the part. Plunge moves begin as the reciprocation axis

decelerates. Therefore, feedrate, acceleration and deceleration should

be considered for all axes involved.

3.

The X axis moves to the secondary reversal point (I).

4.

The plunge pick move (Q) begins as the X axis decelerates to the

secondary reversal point.

5.

The reciprocation and plunge pick moves continue until the plunge

depth (Y) is reached.

6.

After the plunge depth (Y) is reached, reciprocation continues and

the programmed number of spark-out passes are executed.

The format for the G83 cycle is as follows:

G83X__I__Y__J__Z__K__R__Q__L__F__E__P__D__;

Table 16.C summarizes the G83 cycle parameters. For a detailed

description of these parameters, see the text below and page 16-8.

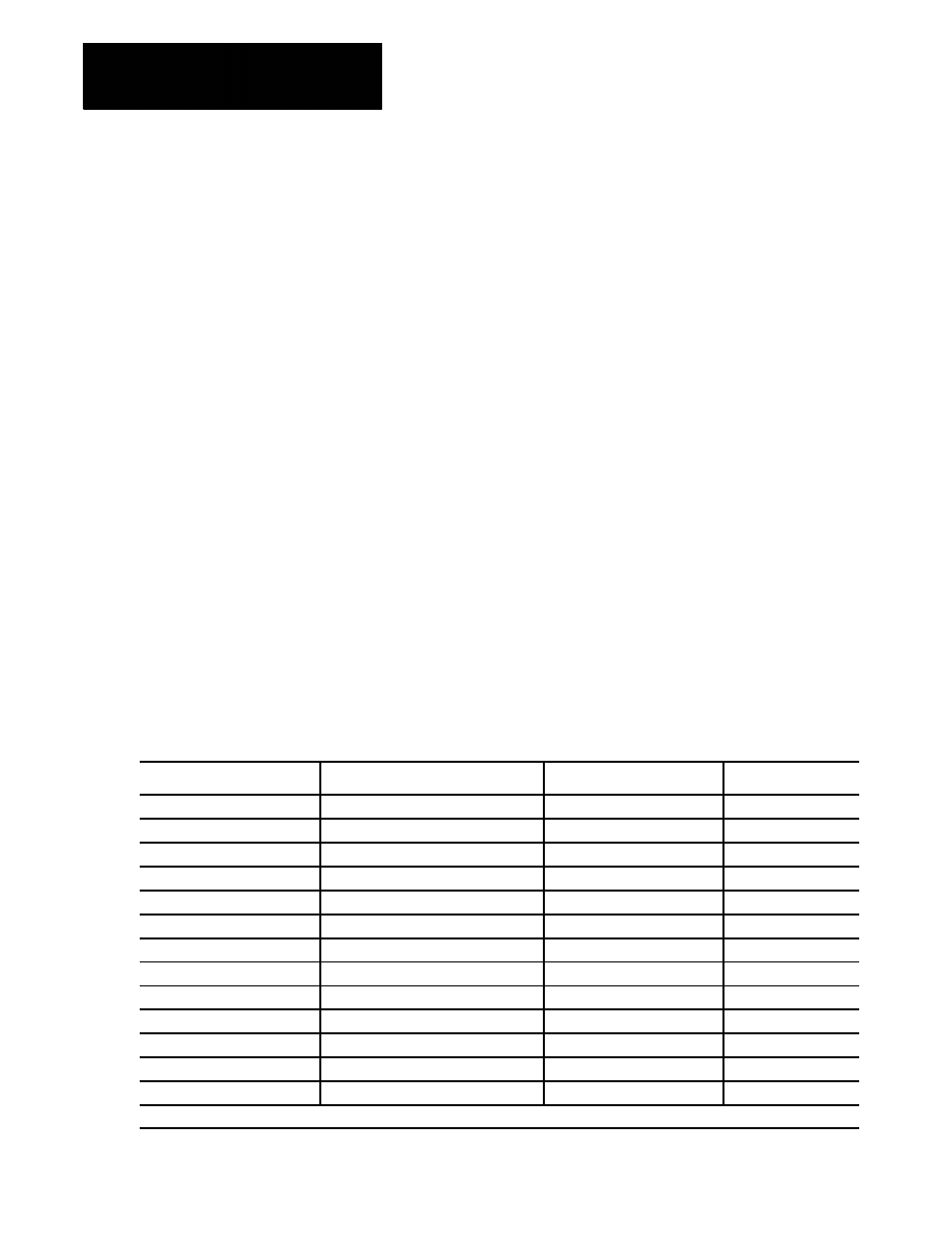

Table 16.C

G83 Cycle Parameters

Parameter:

Definition:

Default Value:

Possible Value:

Non-plane axis

2

reciprocation primary reversal point

from last cycle programmed

abs. or inc.

Reciprocation axis integrand

3

reciprocation secondary reversal point

from last cycle programmed

abs. or inc.

Plane axis 1

2

plunge depth

from last cycle programmed

abs. or inc.

Plane axis 1 integrand

2

plunge pick at start

from last cycle programmed

inc. only

Q

3

plunge pick at crossover

plunge pick at start

inc. only

Plane axis 2

2

crossover amount

from last cycle programmed

abs. or inc.

Plane axis 2 integrand

2

cross pick at primary reversal point

from last cycle programmed

inc. only

R

3

cross pick at secondary reversal point

cross pick at primary reversal

inc. only

L

3

number of spark-out passes

zero

zero to 999

F

2

plunge pick and cross pick feedrate

last feedrate programmed

valid F word

E

3

reciprocation feedrate

from last cycle or last F

valid F word

P

3 for G83 2 for G83.1

dress program number

from last cycle programmed

valid program number

D

3

number of auto-dress executions

zero

zero to 999

1

must be programmed

2

must have been programmed in some previous block if omitted

3

optional

16.5

G83 or G83.1 Incremental

Plane Grinding (Axis 1)