7 feedrates – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 425

Axis Motion

Chapter 12

12-53

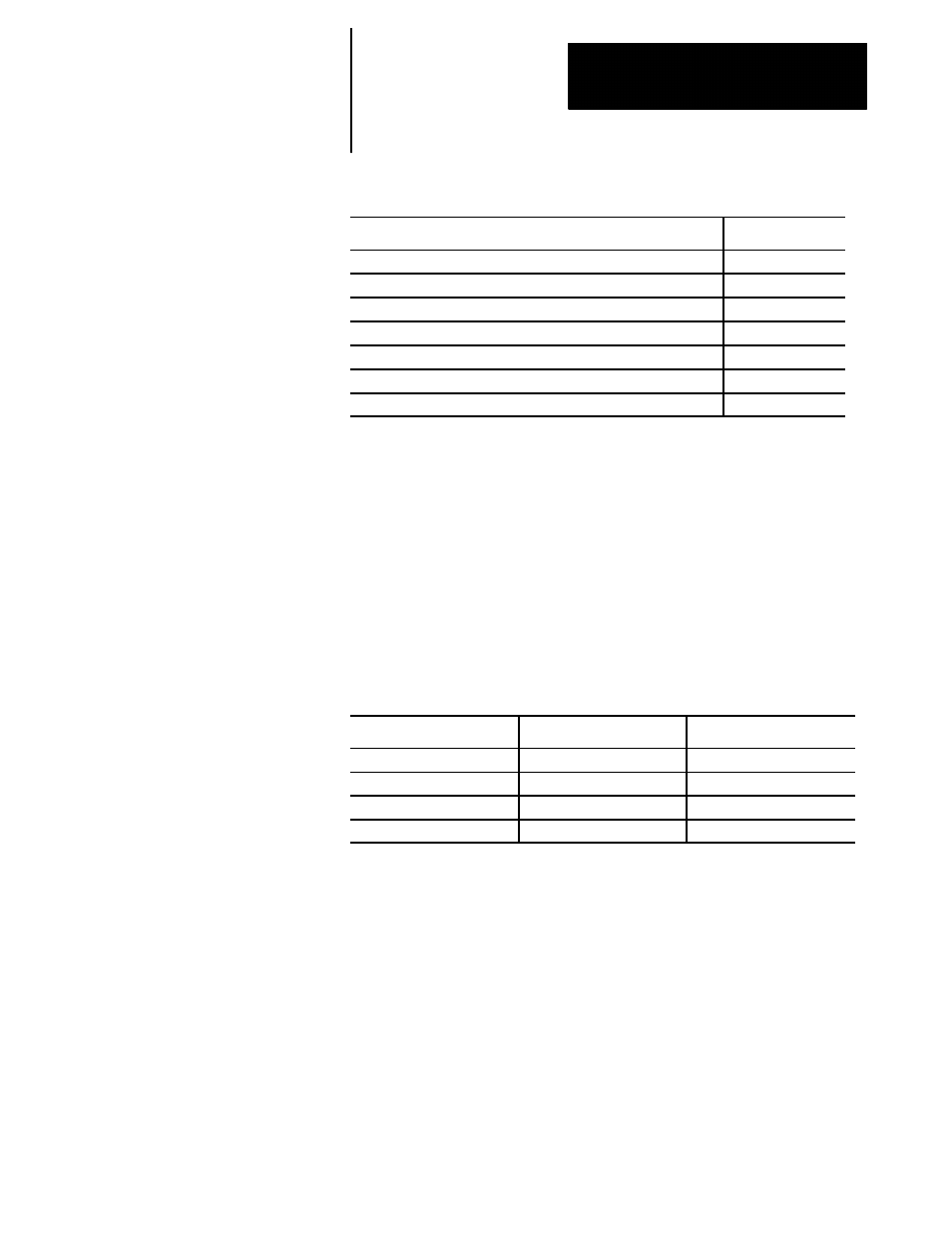

This section covers the following topics:

Topic:

On page:

Feedrates Applied During Dresser/Wheel Radius Compensation

12-54

Feed Per Minute Mode (G94)

12-56

Feed Per Revolution Mode (G95)

12-56

Rapid Feedrate

12-57

Feedrate Overrides

12-58

Feedrate Limits (Clamp)

12-59

Rotary Axis Feedrates

12-60

Feedrates are programmed by an F--word followed by a numeric value.

Feedrates can be entered in a part program block or through MDI. They

become effective in the block in which they are programmed and apply to

all G01, G02 and G03 axis motion. If the block requires rapid traverse

motion (G00), the programmed feedrate is ignored for that block, but is

stored in control memory as the active feedrate.

Feedrates are modal, meaning that they remain active in control memory

unless replaced with a different feedrate programmed with an F--word.

Feedrate modes are either G95 (grinding wheel distance per workpiece

revolution) or G94 (grinding wheel distance per minute). The following

table shows the possible feedrate units depending on axis type.

Active G- code

Linear Axis Feed

Rotary Axis Feed

G71 and G94

millimeters/min.

degrees/min.

G71 and G95

millimeters/rev.

degrees/rev.

G70 and G94

inches/min.

degrees/min.

G70 and G95

inches/rev.

degrees/rev.

Feedrates for linear and circular interpolation are “vector” feedrates. That

is, all axes move simultaneously at independent feedrates so that the rate

along the effective path is equal to the programmed feedrate (see

Figure 12.26).

12.7

Feedrates