Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 501

Dresser/Wheel Radius Compensation

Chapter 15

15-13

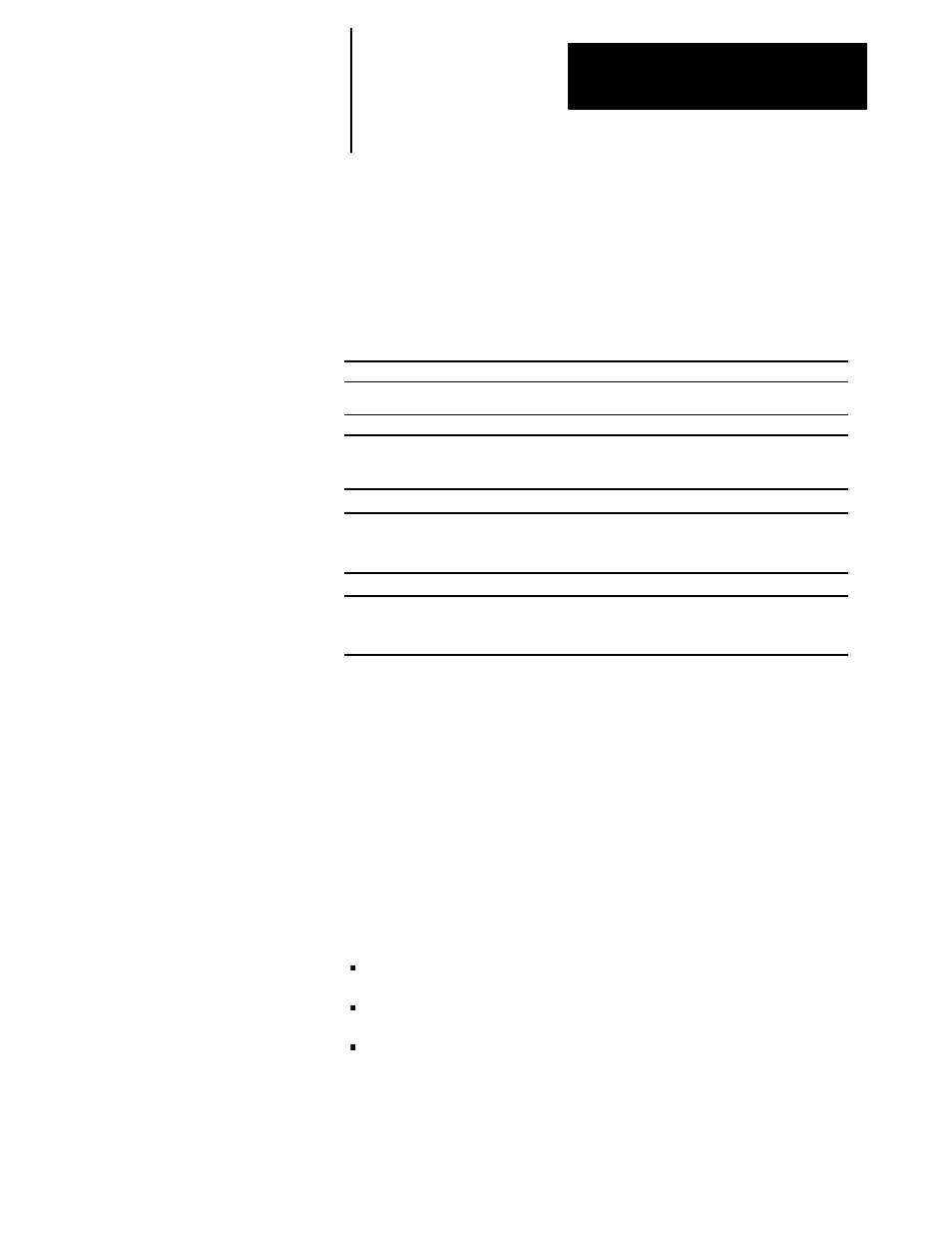

You can activate dresser/wheel radius compensation in various ways.

Example 15.1 illustrates a few examples of activating dresser/wheel radius

compensation.

Example 15.1

Initializing Dresser/Wheel Radius Compensation

Assume: G18 (ZX Plane Selection)

Program Block

Comment

One Block

G42 T1600 X1 Z1;

Sets compensation right, selects dresser/wheel radius offset

number 16, and activates compensation in, move to X1 Z1

Two Blocks

T1600;

Selects dresser/wheel radius number 16

G42 X1 Z1;

Sets compensation right and activates compensation in, move

to X1 Z1

Three Blocks

T1600;

Selects dresser/wheel radius number 16

G42;

Sets compensation right

X1 Z1;

Activates compensation in, move to X1 Z1

Three Blocks

G42;

Sets compensation right

T1600;

Selects dresser/wheel radius number 16

X1 Z1;

Activates compensation in, move to X1 Z1

Important: The T words in the above examples select a length offset

number 00. This cancels any active wheel length offsets. In your program,

the T word should contain both a radius and length offset number.

Important: Any entry move (see page 15-17 for type A and page 15-27

for type B entry moves) into dresser/wheel radius compensation must be a

linear move. You are not allowed to program G41 or G42 commands in a

G02 or G03 circular mode in the initial activation of dresser/wheel radius

compensation. If, however, dresser/wheel radius compensation is already

active, then you can program the G41 or G42 commands in a circular

block to change dresser/wheel radius compensation direction, either left

(G41) or right (G42).

The T word calls these data from the offset tables:

Initial dresser/wheel radius data (from radius table)

Dresser/wheel orientation data (from radius table)

Wheel length offset data (from geometry table, see chapter 13)