Change in dresser/wheel radius during jog retract – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 541

Dresser/Wheel Radius Compensation

Chapter 15

15-53

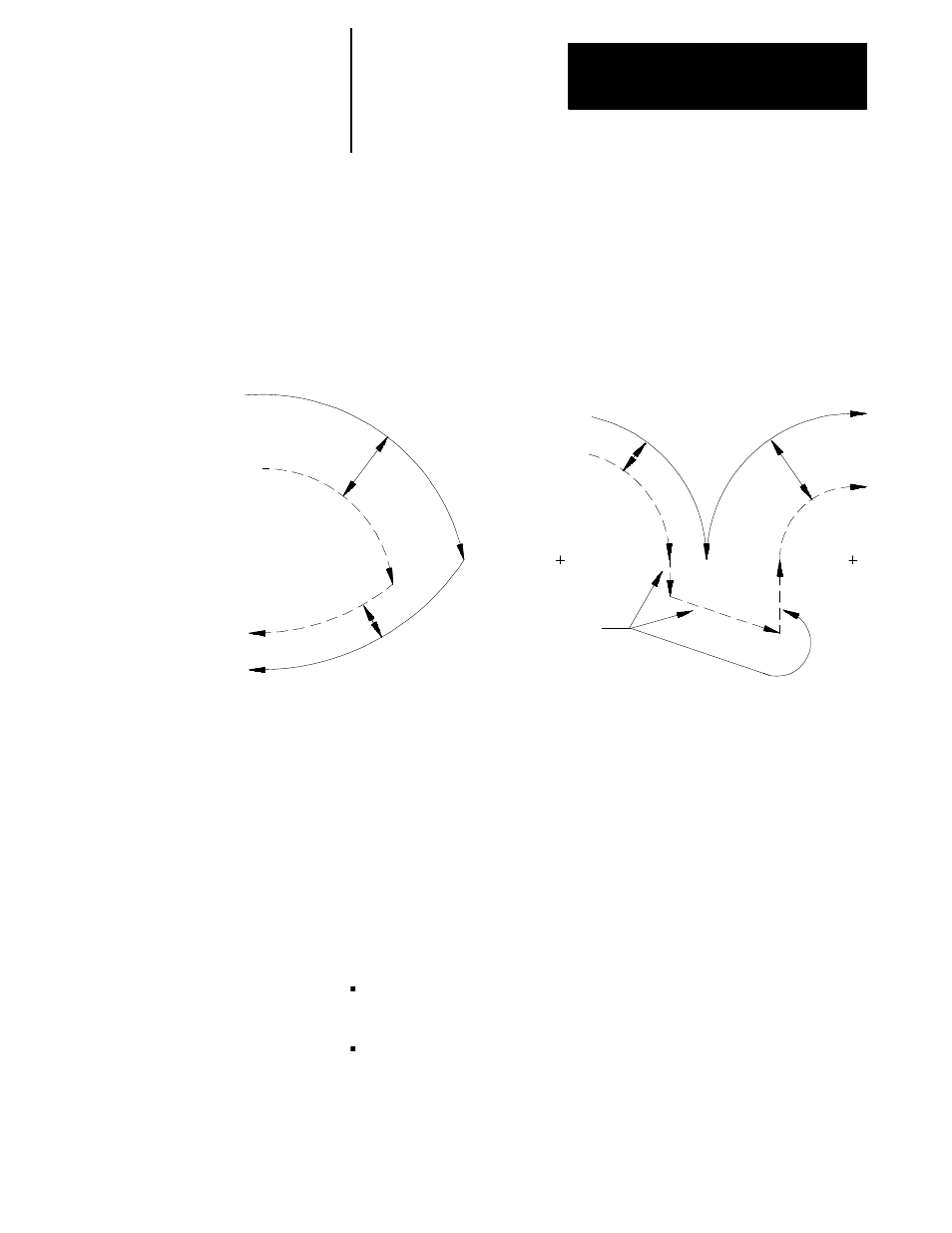

Figure 15.47 describes the path when the programmed moves are

circular-to-circular.

Figure 15.47

Circular to Circular Change in Dresser/Wheel Radius During

Compensation

No control-generated

motion blocks

With control-generated

motion blocks

Programmed

path

Compensated

path

r

1

r

2

r

2

r

2

r

1

r

1

Programmed

path

Compensated

path

Generated blocks

12138-I

Change in Dresser/Wheel Radius During Jog Retract

This section describes the change in the dresser/wheel radius during a jog

retract operation. This is a typical operation because the jog retract feature

is often used when a dresser/wheel becomes worn or is broken. If it is

necessary to replace the dresser/wheel with one of a slightly different

diameter, radius compensation can adjust to the new diameter.

Typically when you perform the jog retract operation, the dresser/wheel is

jogged away from the workpiece and then replaced. After it is replaced,

you have to activate a different dresser/wheel radius offset value. This is

done in either of two ways:

The new offset number is activated by programming a new T word in an

MDI block

The new offset number is activated by using the {ACTIVE OFFSET}

softkey found on the offset table screen. This feature is described in

chapter 4