Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 481

Angled-Wheel Grinding

Chapter 14

14-13

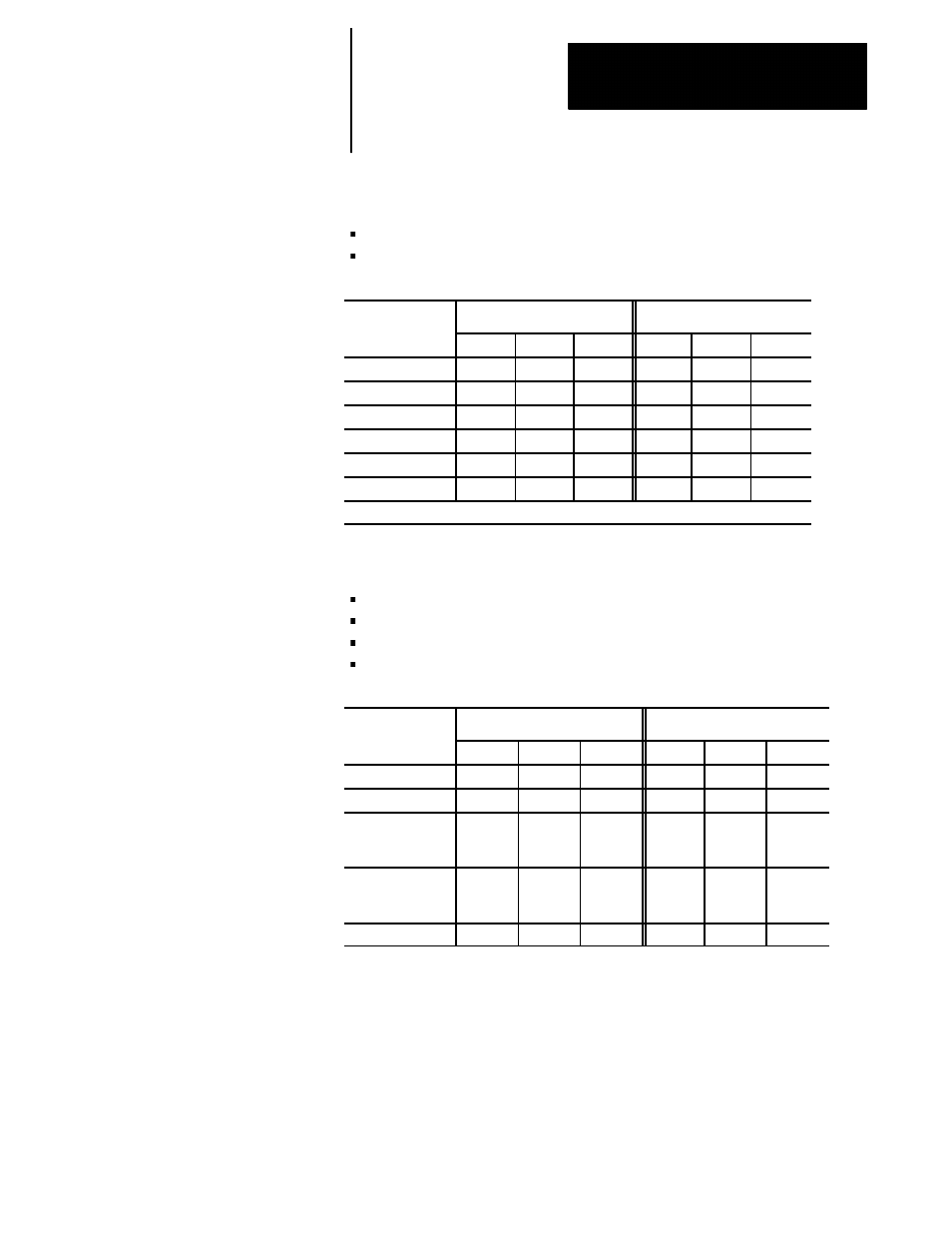

The following table shows the position displays as a program executes

under the following conditions:

in G16.3 normal angled wheel mode

in single block mode.

wheel axis angle of 60 degrees

Program Block:

Program Display:

Absolute Display:

Program Block:

W

Z

X

W

Z

X

G07G00W0Z0;

0.0

0.0

N/D

0.0

0.0

N/D

G01W10Z1F100;

10.0

1.0

N/D

10.0

1.0

N/D

G16.3;

10.0

9.66025

5.0

10.0

1.0

5.0

X6;

12.0

9.66025

6.0

12.0

--.73205

6.0

X4;

8.0

9.66025

4.0

8.0

2.73205

4.0

G15;

8.0

2.73205

N/D

8.0

2.73205

N/D

N/D -- no display is shown for this axis.

The following table shows the position displays as a program executes

under the following conditions:

in G16.4 two step angled wheel mode

in single block mode.

wheel axis angle of 60 degrees

PAL is configured to perform W moves first when moving away from

spindle centerline

Program Block:

Program Display:

Absolute Display:

Program Block:

W

Z

X

W

Z

X

G07G01W10Z1F0;

10.0000

1.0000

N/D

10.0000

1.0000

N/D

G16.4;

10.0000

9.6602

5.0000

10.0000

1.0000

5.0000

X6F100;

STEP1

STEP2

12.0000

12.0000

11.3923

9.6602

6.0000

6.0000

12.0000

12.0000

1.0000

--.7320

6.0000

6.0000

X4;

STEP1

STEP2

12.0000

8.0000

13.1243

9.6602

6.0000

6.0000

12.0000

8.0000

2.7320

2.7320

6.0000

4.0000

G15;

8.0000

2.7320

N/D

8.0000

2.7320

N/D

Graphics

Graphics can be configured to plot the X (virtual) as well as the W (wheel

axis) in any angled-wheel grinding mode (G15, G16.3 or G16.4). No

motion will appear on the graph for the X axis in the G15 mode. Plots of

the wheel axis are orthogonal regardless of your current wheel axis angle.

This can cause graphics to show an part contour not representative of the

actual wheel path relative to the part.