2 activating the in-process dresser – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 713

In-process Dresser

Chapter 21

21-7

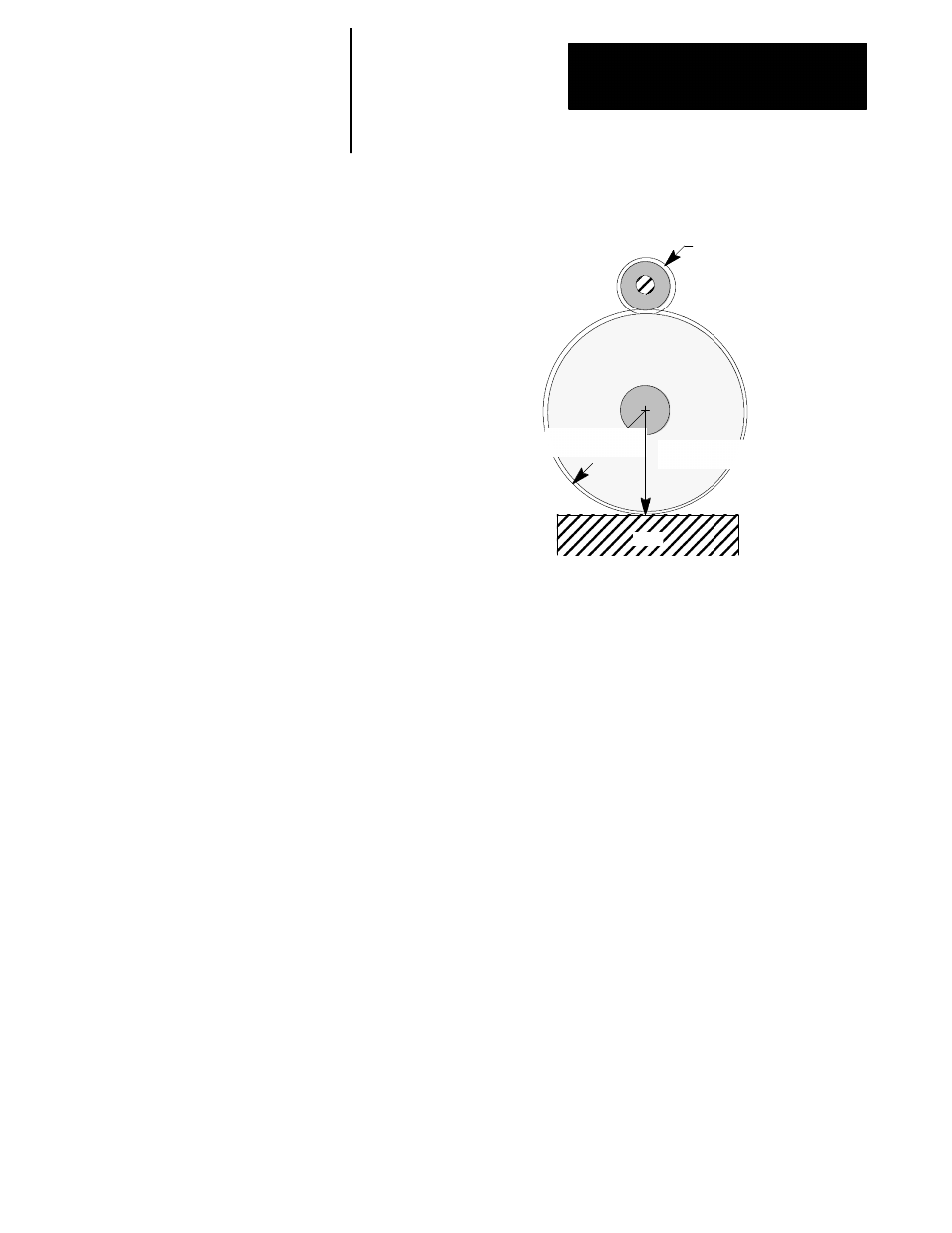

Figure 21.3

In-process dresser should compensate for either length or radius

change (not both)

Either length offset modification or entire wheel

offset modification must be performed here. If

both are active, the control compensates for

dressing amount twice. (Either radius offset #33

or length offset #01, #02, #03, or #04 should be

active)

Radius of

Entire Wheel R33

Over Wheel

Roll Dresser

Length offset modified by

in-process dresser

Part

12096-I

PAL controls the rotation of the actual in-process dresser and the

enabling/disabling of the in-process dresser feature. See the

documentation prepared by your system installer for details. This section

assumes you have already calibrated your dresser axis as described on page

21-12. You must calibrate your dresser axis before the in-process dresser

can be activated.

Dresser Enable

When the in-process dresser is enabled, the control automatically performs

a retract return towards the grinding wheel on the dresser axis. The retract

return amount is the same distance as the “Dresser Retract Distance”

configured on the in-process dresser status page (see page 21-10). This

retract return is only performed if the dresser is currently in a retracted

position (i.e., the dresser does not return when enabled immediately after a

dresser calibration operation).

The feedrate at which the in-process dresser is returned from retract

towards the grinding wheel is configured in AMP as the retract feedrate.

Once the dresser reaches the return position, the control continues to infeed

the dresser in the same direction (towards the wheel) at the configured

dressing rate.

While the in-process dresser is active the dressing axis cannot be

positioned by any other normal means (i.e., cannot be programmed,

jogged, or positioned by the PAL axis mover).

21.2

Activating the In-process

Dresser