8 block look-ahead – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 547

Dresser/Wheel Radius Compensation

Chapter 15

15-59

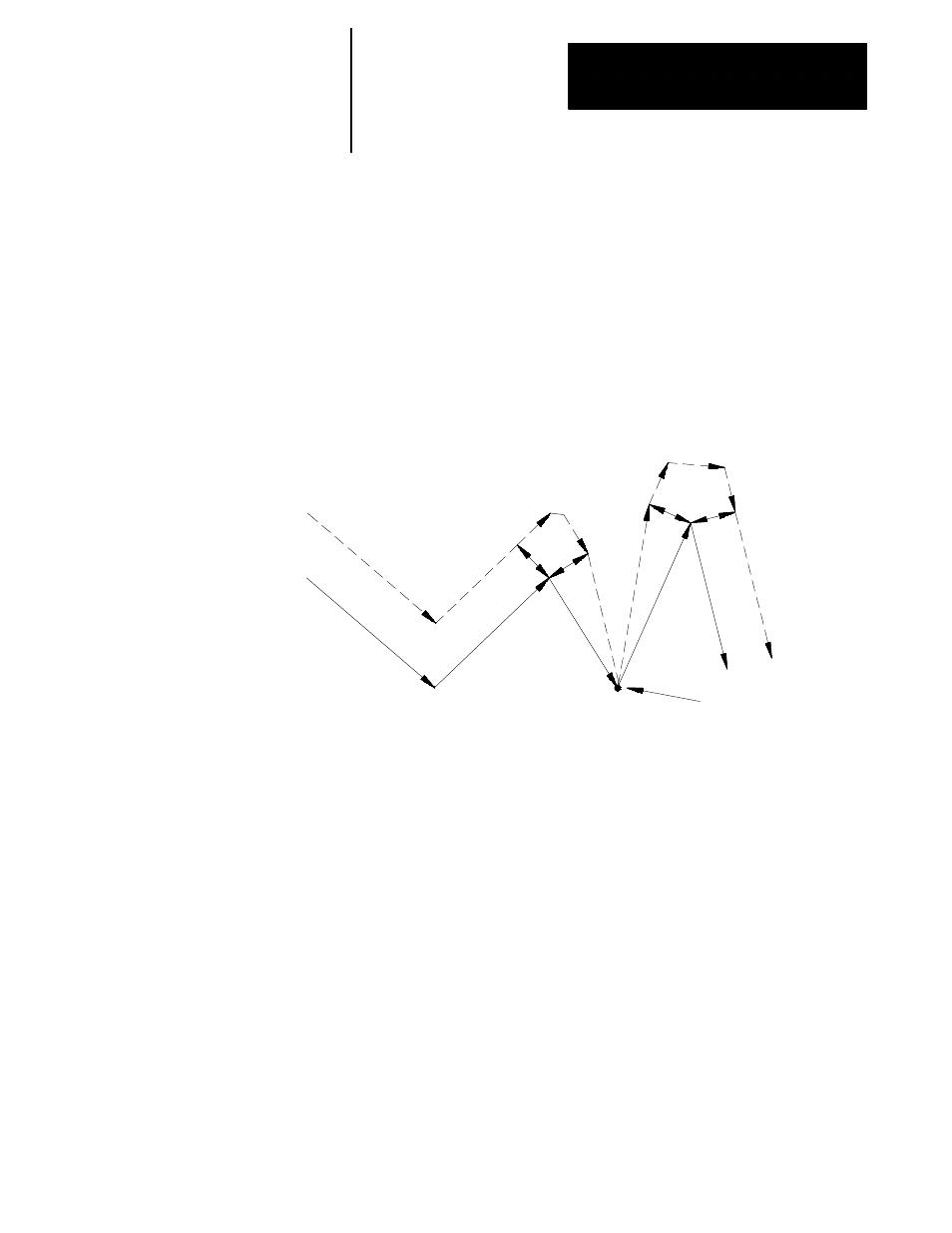

If compensation was not canceled using a G40 command before a change

in the work coordinate system was performed, the control automatically

re-initializes dresser/wheel radius compensation after the new work

coordinate system is established. This is done by using the first move in

the new coordinate system that is in the compensation plane as a entry

move for compensation.

Figure 15.52 gives an example of programming a G92; however, this

would apply to any change in the work coordinate system.

Figure 15.52

Dresser/Wheel Radius Compensation During G92 Offset to Work

Coordinate System

Temporary cancel of

compensation here

N10

N11

N12

N14

N15

G41

N13

r

Programmed

path

12142-I

During normal program execution, the control is constantly scanning ahead

several blocks to set up the necessary motions to correctly execute the

current block. This is called Block Look-Ahead.

The control has 21 set-up buffers. Different features require some of these

set-up buffers. One is always used for the currently executing block.

Dresser/wheel radius compensation requires at least 3 of these buffers.

The control uses any remaining set-up buffers for block look-ahead, with

one buffer used for each block.

At times (especially during dresser/wheel radius compensation) the control

cannot have enough look-ahead blocks to correctly execute the current

block. When this happens, the control automatically starts disabling the

block retrace feature.

The block retrace feature uses one set-up buffer for every re-traceable

block. The number of re-traceable blocks is set in AMP by your system

installer (a maximum of 15 is possible).

15.7.8

Block Look-Ahead