Assigning wheel length offset values – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 75

Chapter 3

Offset Tables and Setup

3-3

Important: The first 4 wheel offset numbers (01-04) are reserved for use

in conjunction with an in-process dresser. When the in-process dresser is

disabled, the control automatically updates these first 4 offset numbers

with the current grinding wheel size. These offset values should not be

manually entered. See chapter 21 for details on using the in-process

dressing feature.

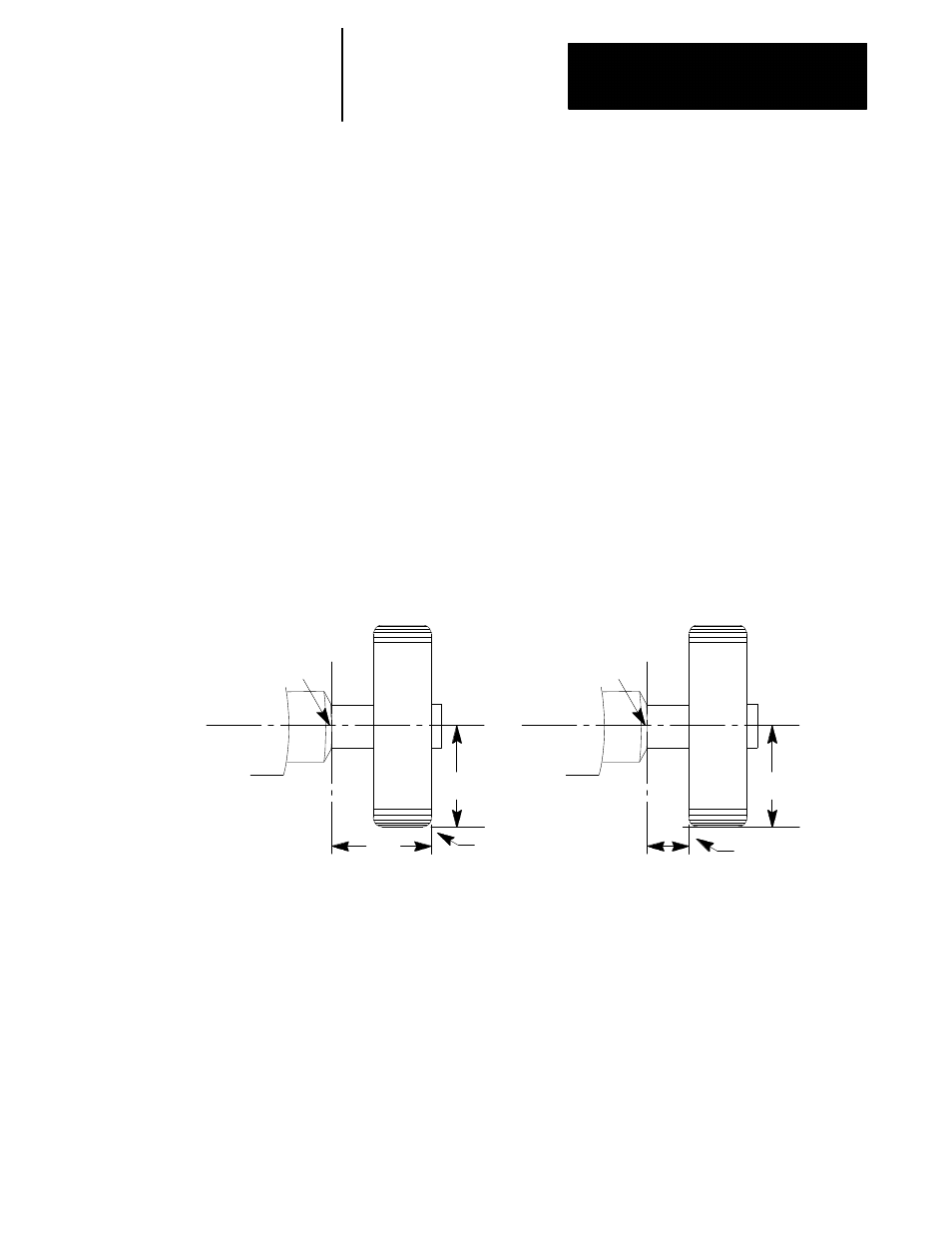

Assigning Wheel Length Offset Values

Use the wheel length offset to compensate for the wheel position as

mounted on the machine. By using the wheel length offset along with

wheel radius and orientation information, a programmer can write a part

program without concern for wheel dimensions and shape. Measure wheel

length values for each axis to define the control point for programming

relative to the wheel gauge point (see Figure 3.2). The same wheel can

have several offset numbers to let the programmer select which part of the

wheel is being controlled.

Figure 3.2

Wheel Length Offsets

Wheel gauge point on

spindle from which wheel

offsets are usually mea-

sured

X length offset

Z

length

offset

X length offset

Z

length

offset

These length offsets

select this point as the

control

point

for

programming

11983-I

Wheel gauge point on

spindle from which wheel

offsets are usually mea-

sured

These length offsets

select this point as the

control

point

for

programming

You can configure each axis on your system to have wheel length offset

values. This manual assumes a two axis Z and X configuration.