Programmable zones – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 486

Angled-Wheel Grinding

Chapter 14

14-18

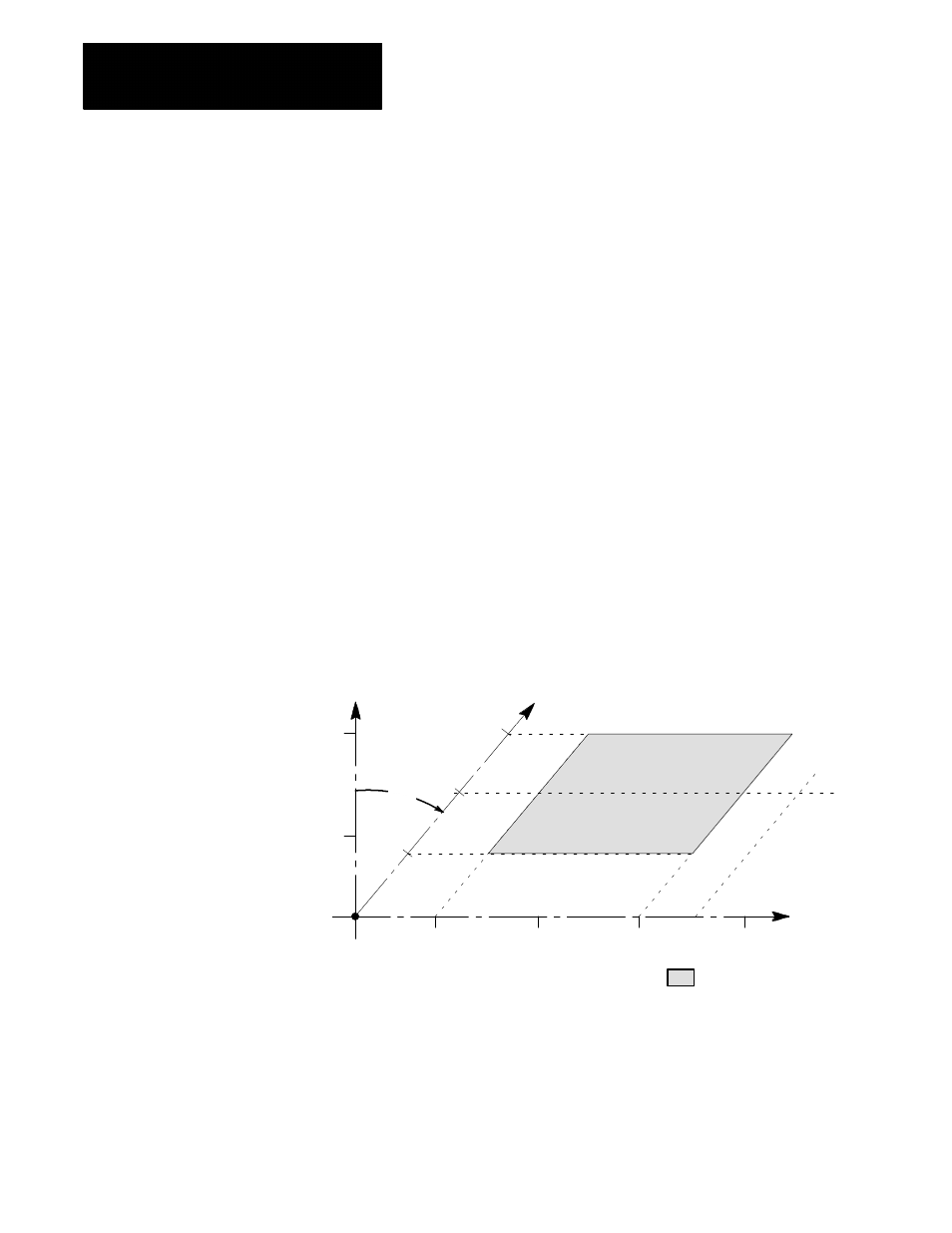

Programmable Zones

For details on what programmable zones are and how they work refer to

page 11-34. Programmable zones can be configured by the system

installer, programmer, or operator. The programmable zones you set up on

an angled wheel grinder are significantly different zones when in angled

wheel mode versus non-angled wheel mode. The virtual axis (X) is used

to perform zone checks when in angled wheel mode. The wheel axis (W)

is checked when not in angled wheel mode. Zones are always checked as

absolute values on their given axes.

Zone values entered either through AMP, the programmable zone table

discussed in chapter 3, or through programming (for zone 3 only), are

always entered for the W axis when in non-angled wheel mode (G15

active). These W values are used at their entered value for the W wheel

axis in non-angled wheel mode. Figure 14.5 illustrates the zone in

non-angled wheel mode. Note that the Z axis values in the figure are

constant and independent of any Z motion created in physical space by the

W axis.

Figure 14.5

Programmable Zone on an Angled-Wheel Grinder

Not in Angled-Wheel Mode

10

10

20

20

+Z

+X

+W

30

40

10

20

30

Protected

Zone

30

°

The minimum and maximum Z and W axis zone

values in this picture are both configured at 10, 30.

Though it appears that in real space if Z is at 35 and

W is at 20 the wheel would be inside of this zone,

that is not the case. All Z axis values must be

calculated parrallel to the W axis to negate any Z

component created by the W axis position.

60

°

60

°

(Z35 X20)