Considerations with chamfering and corner radius – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 398

Axis Motion

Chapter 12

12-26

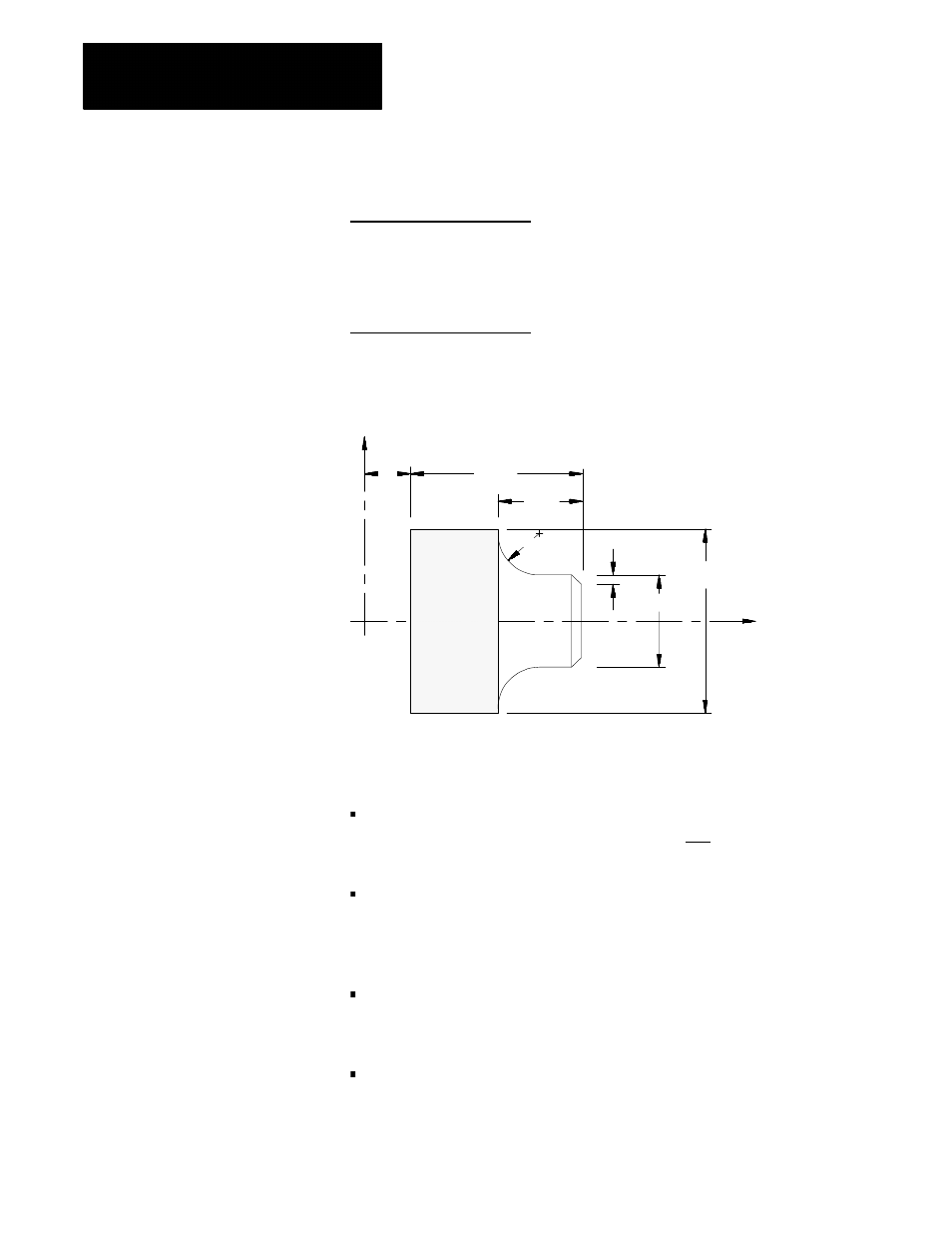

Example 12.16

Radius and Chamfer with QuickPath Plus

N10Z25.X0.F.1;

N20G01A90,C2.;

N30Z15.X20.A180,R5.;

N40X40.;

N50Z5.;

Figure 12.17

Results of Radius and Chamfer, Example 12.16

X

Z

40.0

20.0

2.0

R 5.0

10.0

20.0

5.0

12031-I

Considerations with Chamfering and Corner Radius

If the control is executing in single block mode, the control enters the

cycle stop state after executing the first block and the adjacent chamfer

or corner radius

If non-motion blocks are programmed separating the two intersecting

blocks for the corner radius and chamfer features, the control executes

the chamfer or radius immediately after the first block. The non-motion

blocks are executed after the control has executed the chamfer or radius

Any negative signs programmed with the ,C-- or ,R--words are ignored.

The absolute value of this word is used to cut the chamfer or radius. For

example ,C-10 is executed as ,C10

An error is generated if the length of a chamfer is larger than the

programmed length of the first or second move, or for corner rounding

if the programmed corner radius is so large that the tangent point on

both of the two programmed blocks does not exist