Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 297

Introduction to Programming

Chapter 10

10-19

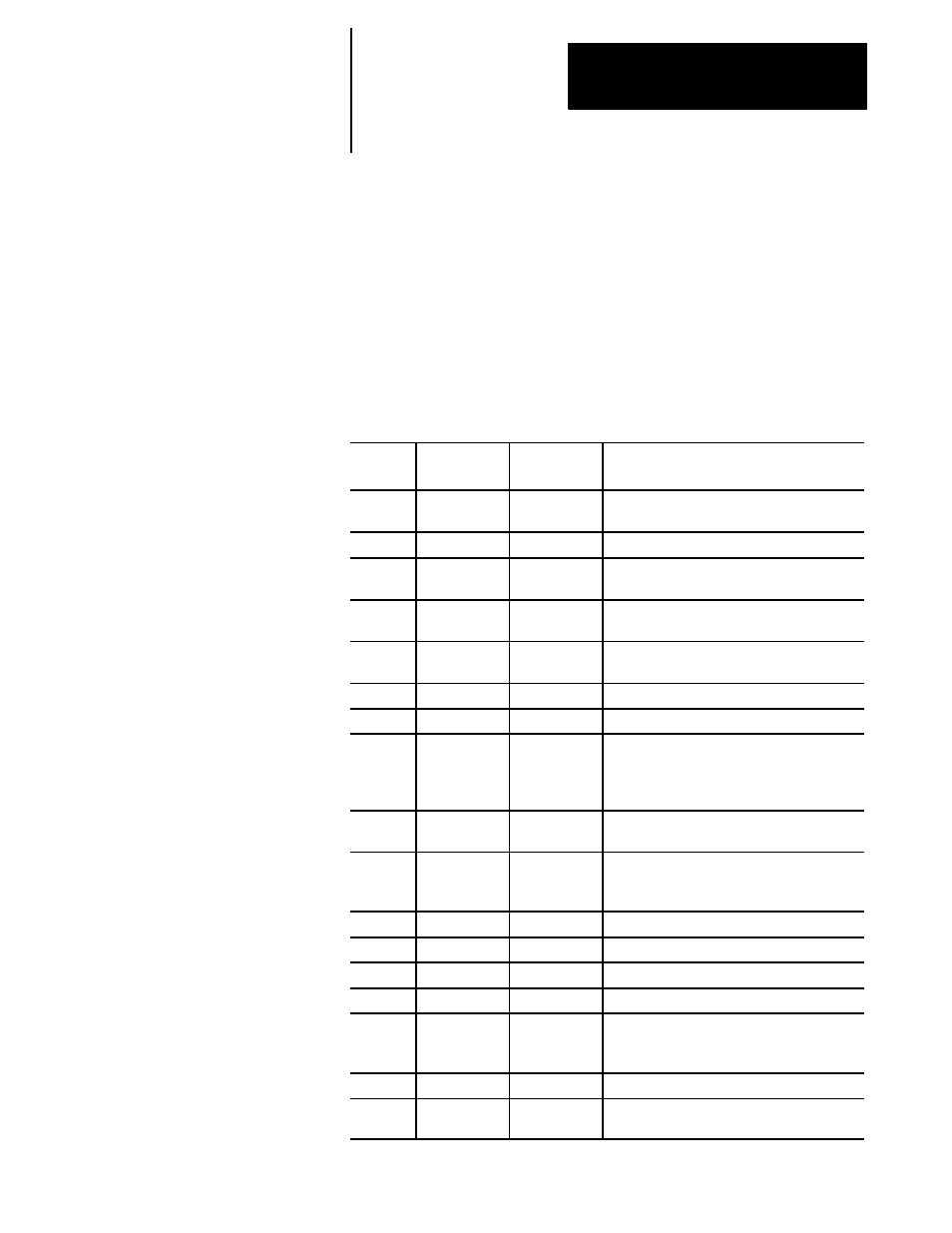

Later sections describe these words in more detail, including variations in

their meanings when they are associated with certain G codes. All words

described in this manual assume the formats and addresses in the following

table have not been changed by your system installer.

Important: The formats in this table indicate the maximum number of

digits to the left and right of the decimal point for each word. In many

cases, they are not valid together since the control allows a maximum of 8

total digits. See your system installer’s manual for specific formats.

Table 10.B

Word Formats and Descriptions

Address

Valid Range

inch

Valid Range

metric

Function

A

8.6

3.3

8.5

3.3

Rotary axis about X (AMP assigned)

Angle in QuickPath Plus programming

B

3.0

3.0

Second miscellaneous function (AMP assigned)

C

8.6

8.6

8.5

8.5

Rotary axis about Z (AMP assigned)

Chamfer length in QuickPath Plus programming

D

8.6

3.0

8.5

3.0

Fixed cycle parameter

Number of dresses in fixed cycle

E

2.6

8.6

3.7

8.5

Thread lead

Reciprocation Feedrate

F

8.6

8.5

Feedrate function (F word)

G

2.1

2.1

Preparatory function (G word)

I

8.6

8.6

8.6

8.6

8.5

8.5

8.5

8.5

X arc center in circular interpolation

X lead in helical interpolation

Parameter in fixed cycles (AMP assigned)

Exit move vector in cutter compensation

J

8.6

8.6

8.5

8.5

Parameter in fixed cycles (AMP assigned)

Exit move vector in cutter compensation

K

8.6

8.6

8.6

8.5

8.5

8.5

Z arc center in circular interpolation

Parameter in fixed cycles (AMP assigned)

Exit move vector in cutter compensation

L

3.0

3.0

Number of repetitions

M

3.0

3.0

Miscellaneous function

N

5.0

5.0

Sequence number

O

5.0

5.0

Program name

P

5.0

5.0

5.3

5.0

5.0

5.3

Subprogram/paramacro program name

Dressing program name

Length of dwell in G04 and fixed cycles

Q

8.6

8.5

Parameter in fixed cycles

R

8.6

8.6

8.5

8.5

Arc radius

QuickPath Plus radius designation