Entering in-process dresser parameters – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 716

In-process Dresser

Chapter 21

21-10

This Parameter:

(paramacro system parameter)

Range:

Indicates:

* DRESSER AMOUNT PER REV

(paramacro #5505)

the amount the dresser is to feed into the grinding wheel for each

revolution of the grinding wheel. When the in-process dresser is

active, this amount of infeed is subtracted from the “Current Wheel

Diameter” at each wheel revolution. This is actually the dresser axis

feedrate (in feed per rev) when it is dressing the wheel.

0 to 9.9999999 [inch]

0 to 0.000000 [mm]

* DRESSER RETRACT DISTANCE

(paramacro #5506)

the distance the dresser roll should retract away from the grinding

wheel when the in-process dresser is deactivated. When in-process

dressing is re-activated, the dresser roll automatically performs a

retract return equal to the amount of the dresser retract distance. If the

dresser is not currently retracted when the in-process dresser is

enabled, the control does not perform the retract return (as is the case

when after a dresser calibration operation). The dresser retract or

retract return can also be performed on request when in the dresser

hold state. Both of these moves are performed on the dresser axis.

0 to 999.9999 [inch]

0 to 99999.999 [mm]

* DRESSER SURF SPEED RATIO

(paramacro #5507)

the ratio of the wheel’s surface speed to the roll dresser surface

speed. A ratio of 1.00 would rotate the dresser and the wheel at the

same relative surface speed. A ratio of 0.50 would rotate the dresser

at one half the surface speed of the wheel. A ratio of 1.50 would

rotate the dresser at one and one-half times the surface speed of the

wheel. Surface speed of the wheel is controlled through your part

program and CSS. Surface speed of the roll dresser is controlled

through PAL and calculated from the “Dresser Roll Diameter”,

“Dresser Surface Speed Ratio”, and the current surface speed of the

grinding wheel. The sign of this parameter indicates the direction that

the dresser will rotate relative to the grinding wheel: “+” equals the

same direction and “--” equals the opposite direction.

0 to 99999.00

* This parameter can be configured by the operator on this screen. Other parameters are assigned by the control or PAL during calibration or dressing.

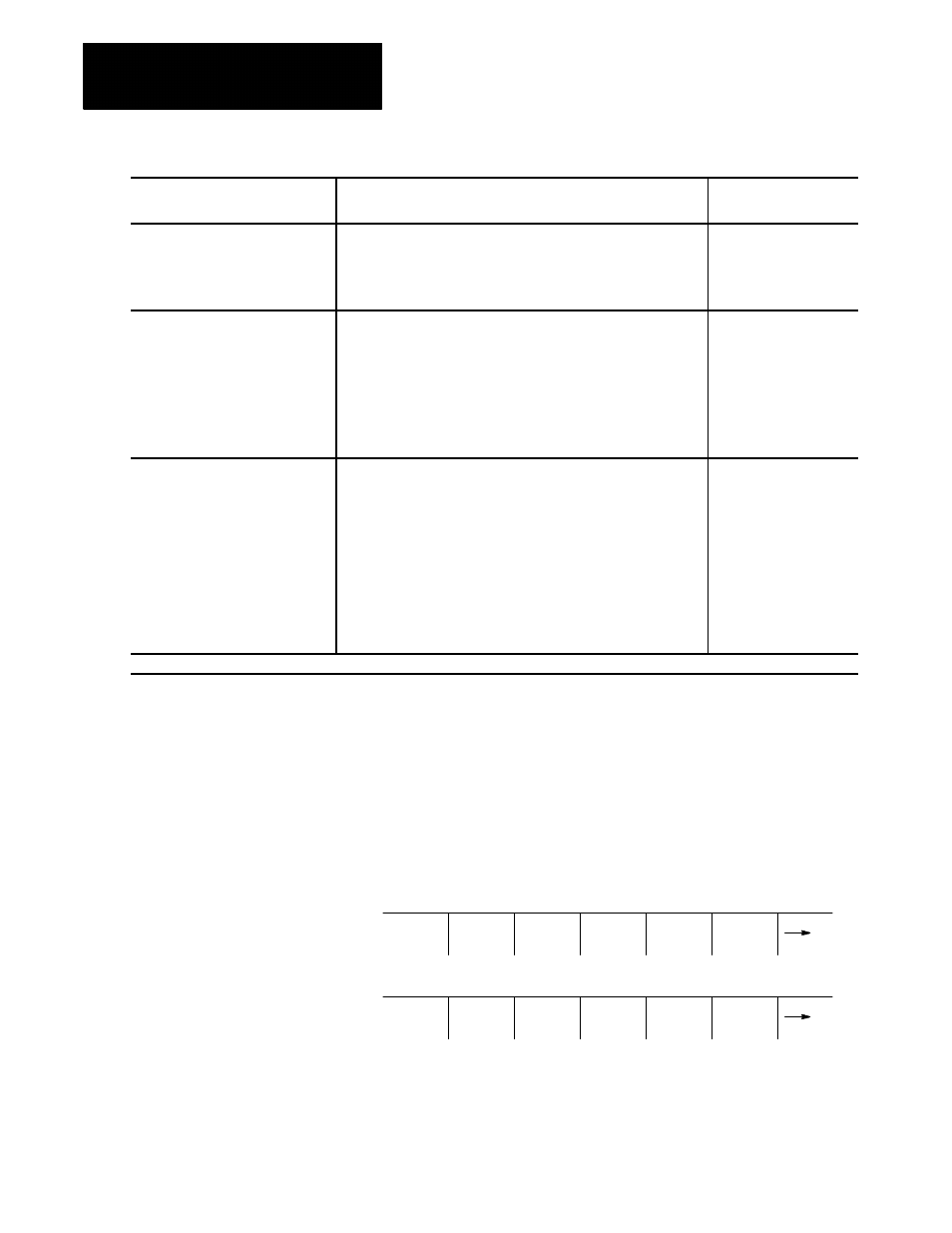

Entering In-process Dresser Parameters

This section covers entering parameter values into the in-process dresser

table manually. You can also enter values in this table through

programming with paramacro system parameters (#5500-#5509). See

chapter 20 for details on assigning values to system parameters.

1.

Press the {OFFSET} softkey on the main menu screen.

(softkey level 1)

PRGRAM

MANAGE

OFFSET MACRO

PARAM

PRGRAM

CHECK

SYSTEM

SUPORT

FRONT

PANEL

ERROR

MESAGE

PASS-

WORD

SWITCH

LANG