1 altering work coordinate systems (g10l2) – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 324

Coordinate Control

Chapter 11

11-8

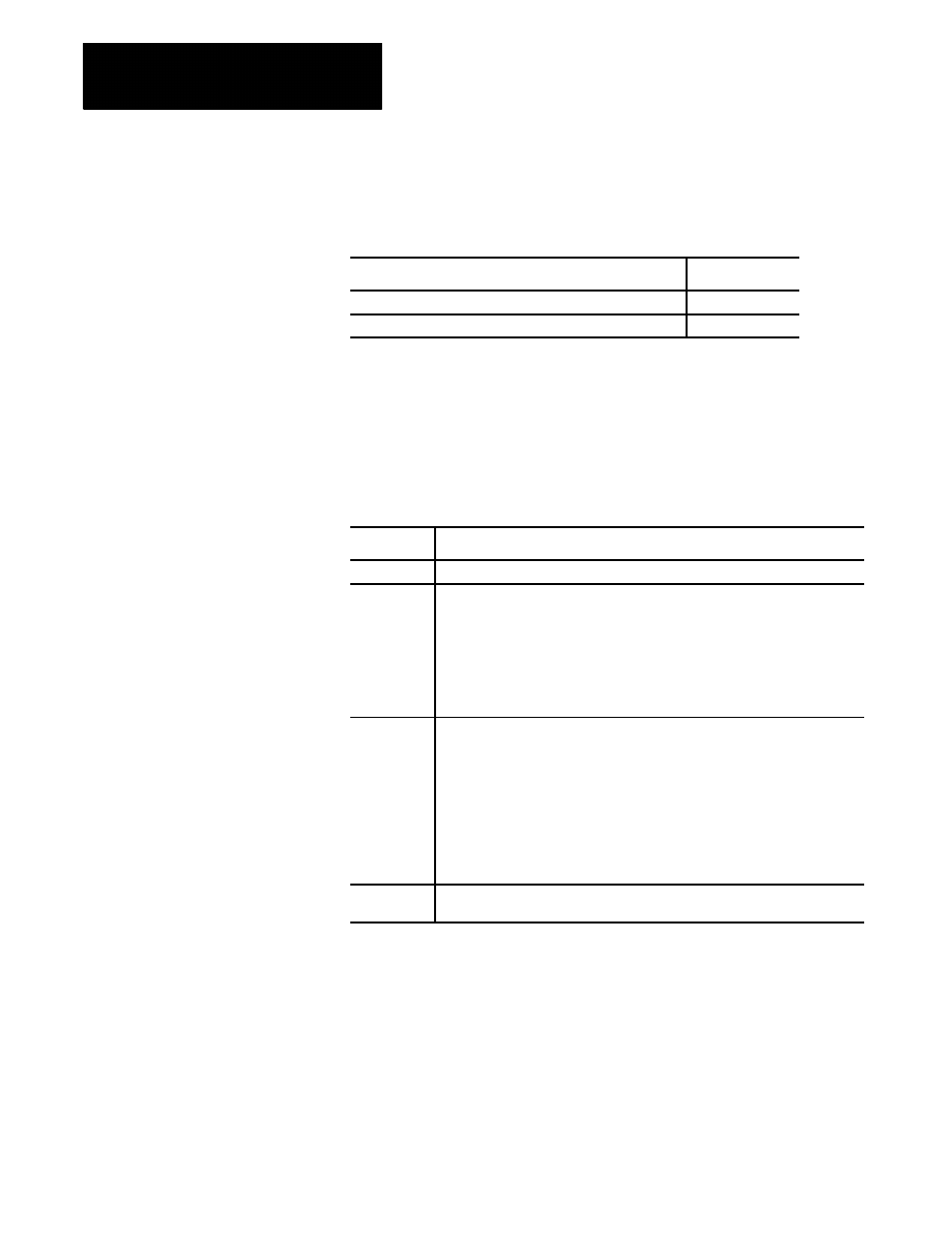

There are 3 methods to change the value of a work coordinate system zero

point in the work coordinate system table. You can find two methods in

these chapters:

Method:

Chapter:

Manually alter the work coordinate system table

3

Alter the paramacro system parameter values 5221 - 5386

20

The third method, the one described in this chapter, alters the work

coordinate system table through G10 programming. Changing the values

in the table by using any of these methods does not cause axis motion;

however, it does immediately shift the active coordinate system by the

amount entered. The format for altering the work coordinate systems

using G10 is as follows:

G10 L2 P__ O__ X__ Z__;

Where :

Tell(s) the control:

L2

that you want to alter the coordinate system tables.

P__

which coordinate system (G54 through G59.3) you want to work on. P1 through

P9 correspond to the work coordinate systems G54 through G59.3.

P1 = G54 work coord. system

P6 = G59 work coord. system

P2 = G55 work coord. system

P7 = G59.1 work coord. system

P3 = G56 work coord. system

P8 = G59.2 work coord. system

P4 = G57 work coord. system

P9 = G59.3 work coord. system

P5 = G58 work coord. system

O__

whether the value entered for the diameter axis is a radius or diameter value. (O

is non-modal, and it applies to cylindrical grinders only)

O1=value entered for the diameter axis is a radius value.

O2=value entered for the diameter axis is a diameter value.

Important:

If you program O1 or O2 in a G10 code, the G10 code is not

affected by a previously programmed G07 or G08 (radius/diameter

programming). However, if no O code is specified, or if the O code is out of

range (for example, O3), then the G10 code is affected by a G07/G08.

X_Z_

the location of the zero point of the specified work coordinate system relative to

machine coordinate system.

Important: You cannot program G10 blocks when dresser/wheel radius

compensation is active.

11.2.1

Altering Work Coordinate

Systems (G10L2)