Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 467

Tool Control Functions

Chapter 13

13-5

You can enter data in the wheel geometry table and radius/orientation

offset table through programming. This section describes the use of the

G10 command for loading these offset tables.

Important: Only the value in the table changes when a G10 modifies a

table value. If the value just changed with a G10 is currently being used

by the control, the value of the active offset does not changed until it is

called again from the offset table using a T word.

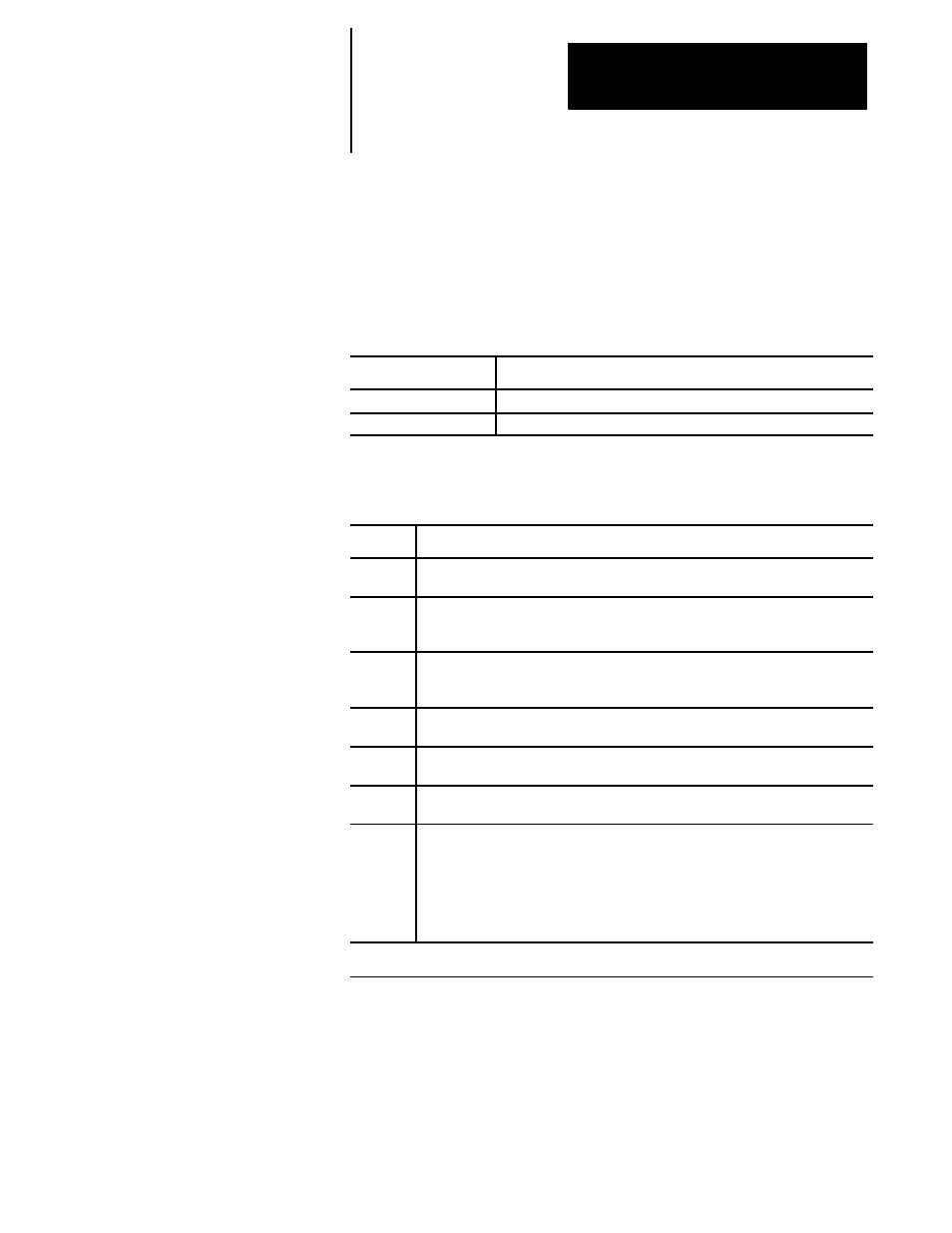

When the control is in:

any values entered in an offset table using the G10 command are:

incremental mode (G91)

added to the currently existing offset values.

absolute mode (G90)

replace the currently existing offset values.

Use this format to modify the offset tables with a G10:

G10 L10 P__ X__ Z__ R__ Q__ T__ O__

Where :

Is :

L10

determines the table being modified.

L10

-Modifies the wheel geometry and radius offset tables

P

the offset number that is having its values changed is specified with the P word. The P

word must be a 2-digit number specifying the radius/orientation offset number and/or

the wheel geometry offset number being modified.

X

*

the value to add to or replace the wheel length offset for the X-axis. This value can be

a diameter or radius value if using a cylindrical grinder as determined with the O word.

This value is entered into the wheel geometry offset table.

Z

*

the value to add to or replace the tool length offset for the Z-axis. This value is entered

into the wheel geometry offset table.

R

the value to add to or replace the dresser/wheel radius compensation amount. This

value is entered into the radius offset table.

Q

the value to add to or replace the dresser/wheel radius compensation orientation

value. This value is entered into the radius offset table.

O

determines if the value being entered into the offset table is a radius or diameter value.

This applies only when setting data for the control’s diameter axis (typically the axis

perpendicular to the spindle) on a cylindrical grinder. If no O word is programmed, the

control uses the current radius/diameter mode active on the control.

O1-indicates a radius value

O2-indicates a diameter value

Surface grinder applications should not program an O word.

*

indicates the axis name configured on your machine. This manual assumes a (ZX) 2 axis machine

configuration.

Any values not specified in the G10 block remain in the table unchanged.

13.2

Programming Changes to

Wheel Geometry and Radius

Offset Tables (G10L10)