Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 600

Cylindrical Grinding Fixed Cycles

Chapter 17

17-26

Q -- plunge shift. The value entered here is an incremental value used to

indicate the distance that the Z axis is to shift after the plunge axis has

retracted. This shift takes place after the plunge axis has retracted and is

executed at the rapid feedrate for the Z axis.

If no value is entered for this then no shift is made. If a value greater than

or equal to Z is entered, then the shift is made only to the last plunge point

defined by Z. If the sign of the value entered here sends the axis away

from the last plunge point instead of towards it, an error is generated.

L, F, E, P, and D -- These parameters were described on page 17-9.

The format for the G86 cycle is as follows:

G18;

G86Z__X__L__F__P__;

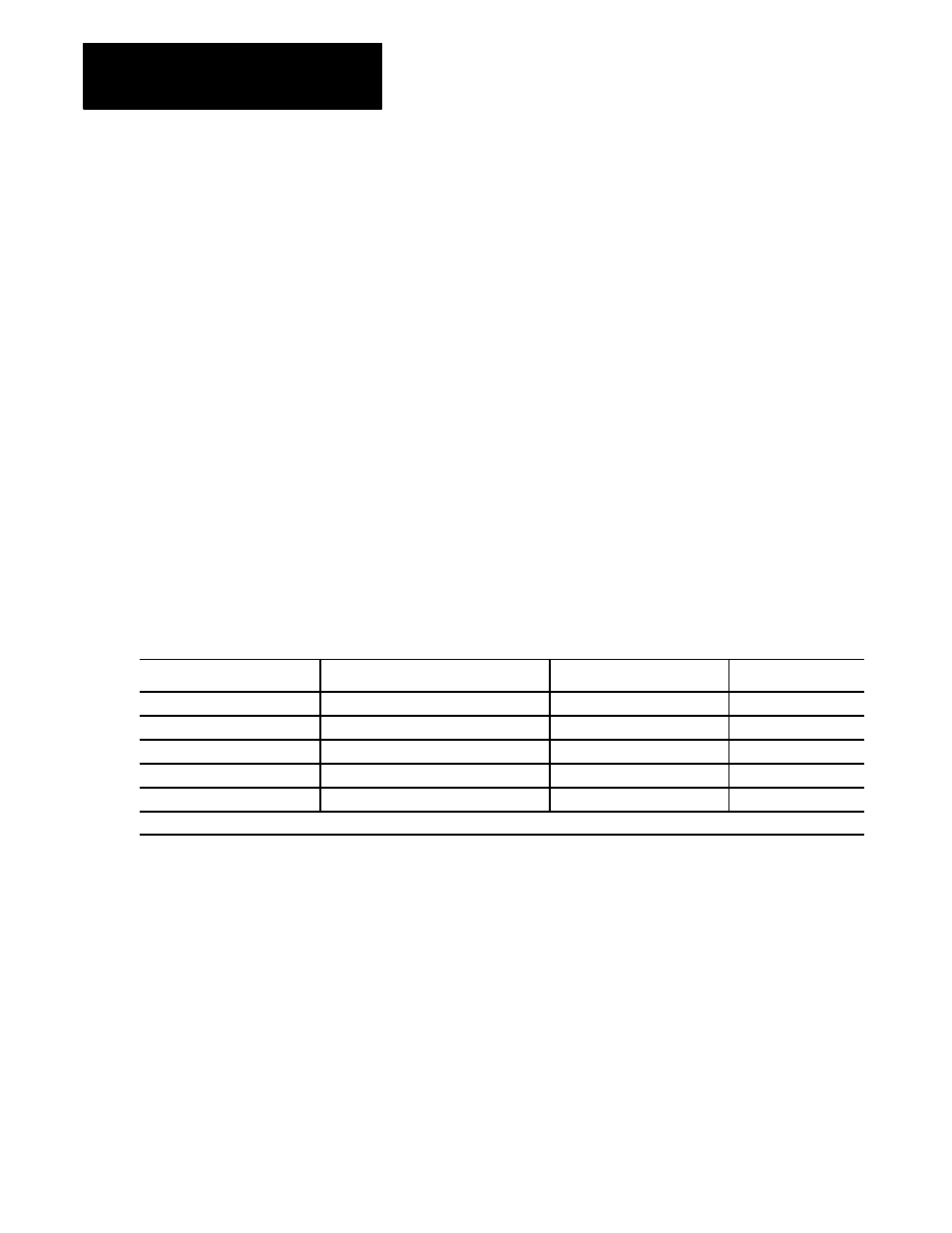

Table 17.F summarizes the G86 cycle parameters. For a detailed

description of these parameters, see the text below and page 17-9.

Table 17.F

G86 Cycle Parameters

Parameter:

Definition:

Default Value:

Possible Value:

Plane axis 1

1

plunge end point

value must be programmed

abs. or inc.

Plane axis 2

1

plunge end point

value must be programmed

abs. or inc.

L

3

number of spark-out revolutions

zero

zero to 999

F

2

plunge feedrate

last feedrate programmed

valid F word

P

3 for G86 2 for G86.1

dress program number

from last cycle programmed

valid program number

1

must be programmed

2

must have been programmed in some previous block if omitted

3

optional

Figure 17.7 shows the axis motions that make up the G86 shoulder

grinding cycle. This figure assumes that the ZX plane (G18) is active.

17.8

G86 or G86.1 Shoulder

Grinding