Dresser radius corner radius entire wheel radius – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 77

Chapter 3

Offset Tables and Setup

3-5

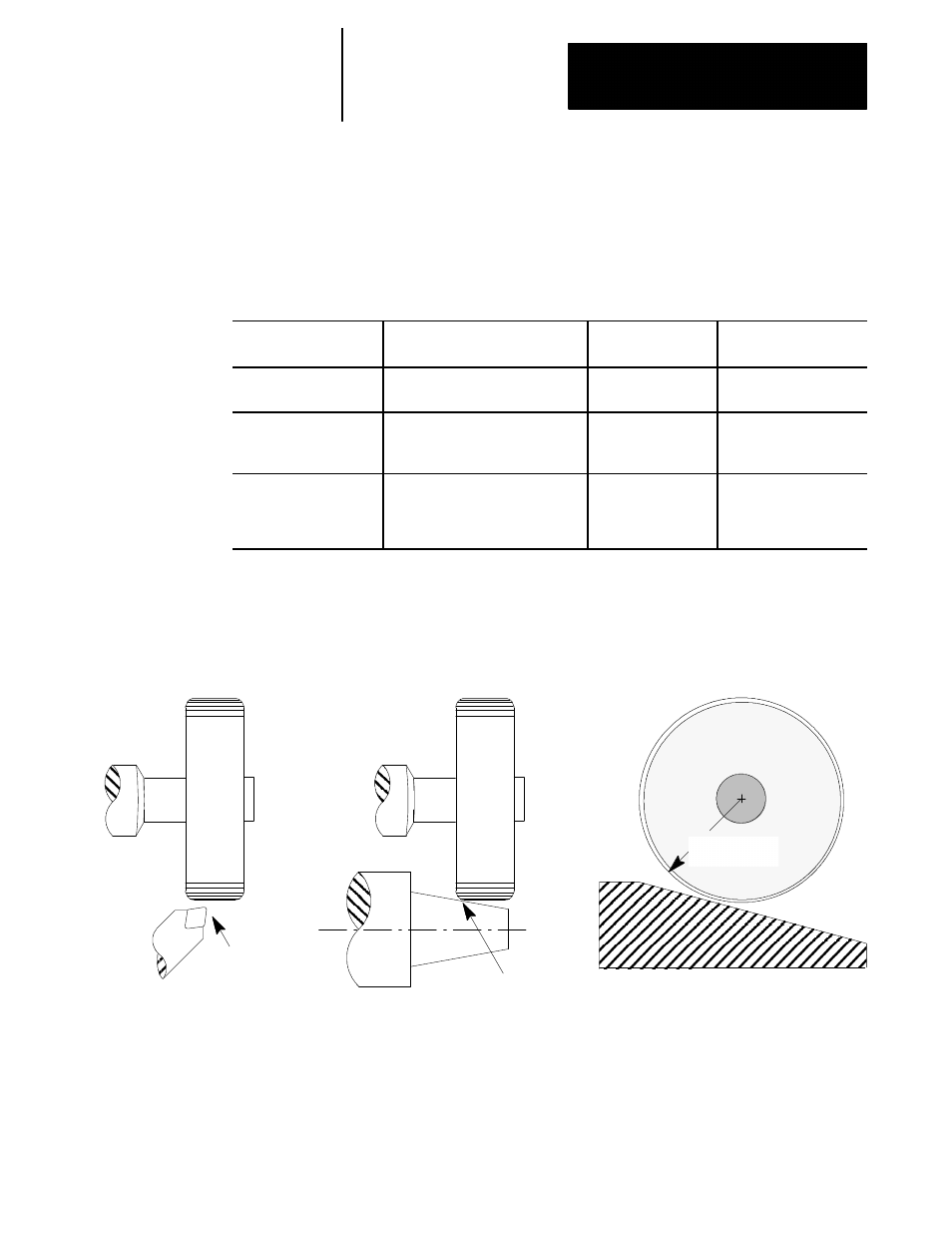

The dresser radius and corner radius compensation schemes use the same

radius table to store a radius value. The entire wheel radius scheme stores

the entire wheel radius in paramacro variable #5508. Which dresser/wheel

radius compensation scheme to use on your system depends on the current

application of your grinder. See chapter 15 for details on how to properly

implement these schemes.

Dresser/Wheel Radius

Compensation Scheme

Length Offsets

Coordinate System

Offset (G54-G59.3)

Dresser/Wheel Radius

Compensation

Dresser Radius

Shifted on Z and X axis to wheel

control point

Shifted to point on

dresser tip

On radius of diamond

dresser

Corner Radius

Shifted on Z and X axis to wheel

control point

Shifted to point on part

being machined

On radius of wheel corner

where Z and X length

offset is located

Entire Wheel Radius

Shifted on Z to control point of wheel,

Y offset is taken into consideration

with dresser/wheel radius

compensation

Shifted to point on part

being machined

On entire radius of wheel

Figure 3.3

Dresser/Wheel Radius Compensation Schemes

Dresser Radius

Corner Radius

Entire Wheel Radius

(common for both cylindrical

and surface grinding applications)

(common for both cylindrical

and surface grinding applications)

(almost exclusively used for surface grinding)

Radius of

dresser tip

Radius of

wheel corner

Radius of

Entire Wheel

11984-I