3 what this manual contains – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 16

Chapter 1

Using This Manual

1-2

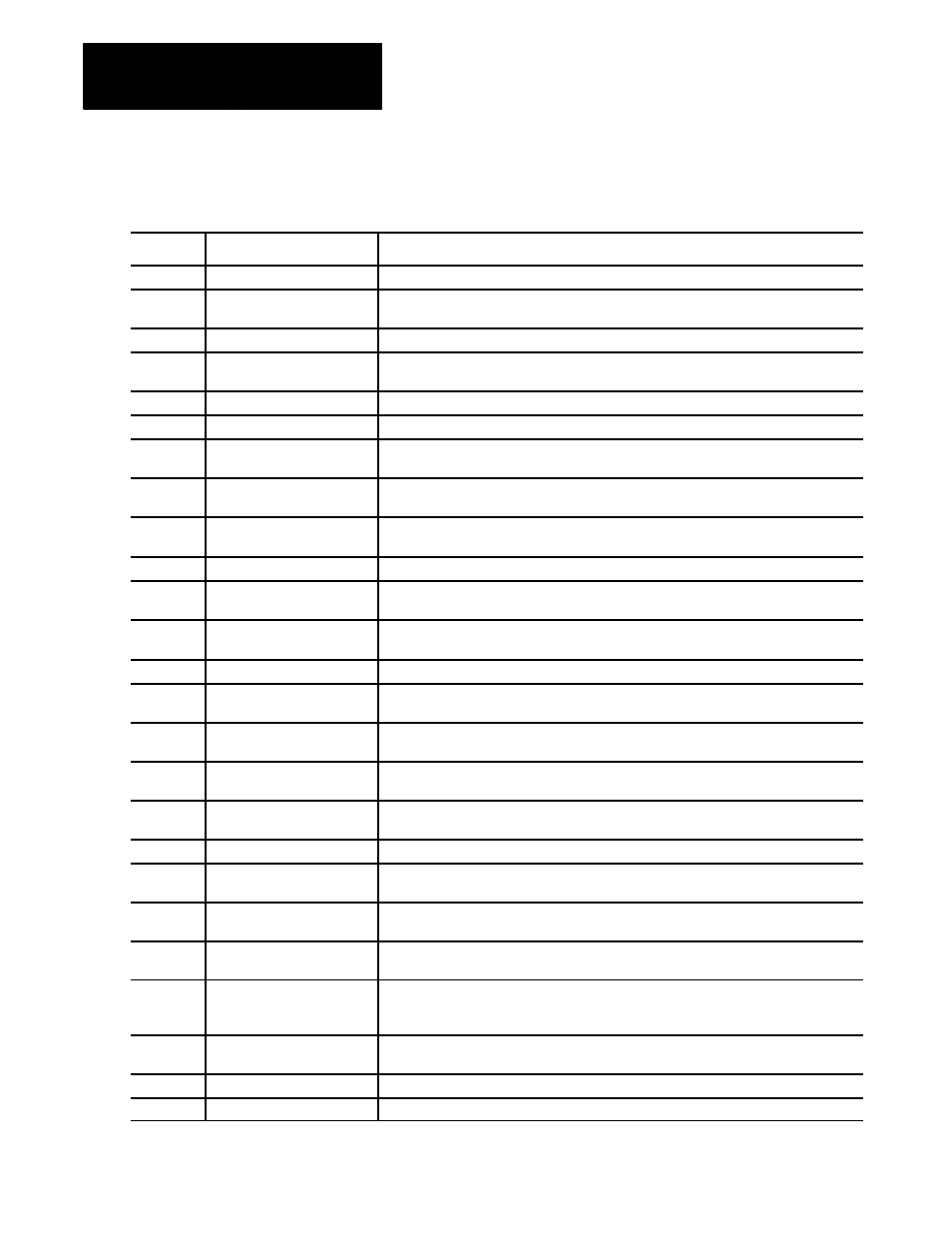

This table contains a brief summary of each chapter.

Chapter

Title

Summary

1

Manual Overview

Manual overview, intended audience, definition of key terms, how to proceed.

2

Operating the Control

A brief description of the control’s basic operation including power-up, MTB panel, operator

panel, access control, and E-STOP.

3

Offset Tables and Setup

Basic setup of the offset table, other initial operating parameters.

4

Manual and MDI Operation

How to use the manual operate mode, including homing the machine, jog hand-wheel, jog

continuous, and jog increment. Also covered are the basics for MDI operation.

5

Editing Programs

How to create, edit,and save a part program on line.

6

Editing Part Program Off Line

How to create, edit, and save a part program from ODS off line.

7

Running a Program

How to select and execute a program automatically. This covers program checking as well

as part production. Also details on special running conditions.

8

Displays and Graphics

How to access and interpret the different position displays. How to use the Quick Check

and Active Program graphics features.

9

Communications

Communications with peripheral devices. Includes sections on communication port

parameters, inputting and outputting AMP, PAL

™

, Offsets, and programs.

10

Introduction to Programming

Tape format, structure and format of the programming language for the control.

11

Coordinate Control

The different coordinate systems and offsets to them. Also sections on plane selection,

overtravels, absolute/ incremental and inch/metric modes.

12

Axis Motion

G-words that define how the wheel is positioned to the endpoint of a move. Also sections

on spindle control, QuickPath Plus

™

programming, dwell, and mirroring.

13

Wheel Length Offset

Selecting a wheel. Activating and deactivating wheel length offsets.

14

Angled Wheel Grinding

Description and use of cylindrical grinders with an angled wheel. The angled wheel is a

non-orthogonal wheel axis.

15

Dresser/wheel Radius

Compensation

A description of the dresser/wheel radius compensation feature that offsets for different

dresser/wheel diameters.

16

Surface Grinding Cycles

Description and use of the fixed cycles (canned cycles) for surface grinders and the

G-words and parameters used to define them.

17

Cylindrical Grinding Cycles

Description and use of the fixed cycles (canned cycles) for cylindrical grinders and the

G-words and parameters used to define them.

18

Turning Operations

Rough contouring routines and threading including tapered and multi-lead threading.

19

Skip and Gauging Cycles

Description and use of the 9/Series probing features. Included in this is the wheel

measuring gauge feature.

20

Paramacros

Description and use of paramacros, including calling, arithmetic functions, looping, decision

making, etc.

21

In-Process Dresser

Description on how the in-process dresser operates. The in-process dresser interaction with

features such as offset tables and the in-process dresses table are also covered.

22

Program interrupts / Dressing

Interrupts

A description of the program interrupt and dressing interrupt features. These features are

used to call a subprogram or paramacro program whenever a signal corresponding to that

program is sent to PAL by the operator or requested by a grinder cycle.

Appendix A

Softkeys

A description of softkeys and their functions for softkey levels 1 and 2. Also the softkey tree

displaying all levels of softkeys and their location is shown.

Appendix B

Error and Operator Messages

An alphabetical listing of 9/Series error/warning messages, each with a brief description.

Appendix C

G-Code Tables

A listing of the G-codes used to program the 9/Series controls.

1.3

What This Manual Contains