1 using {qpath+ prompt} sample patterns – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 139

Editing Programs On Line

Chapter 5

5-19

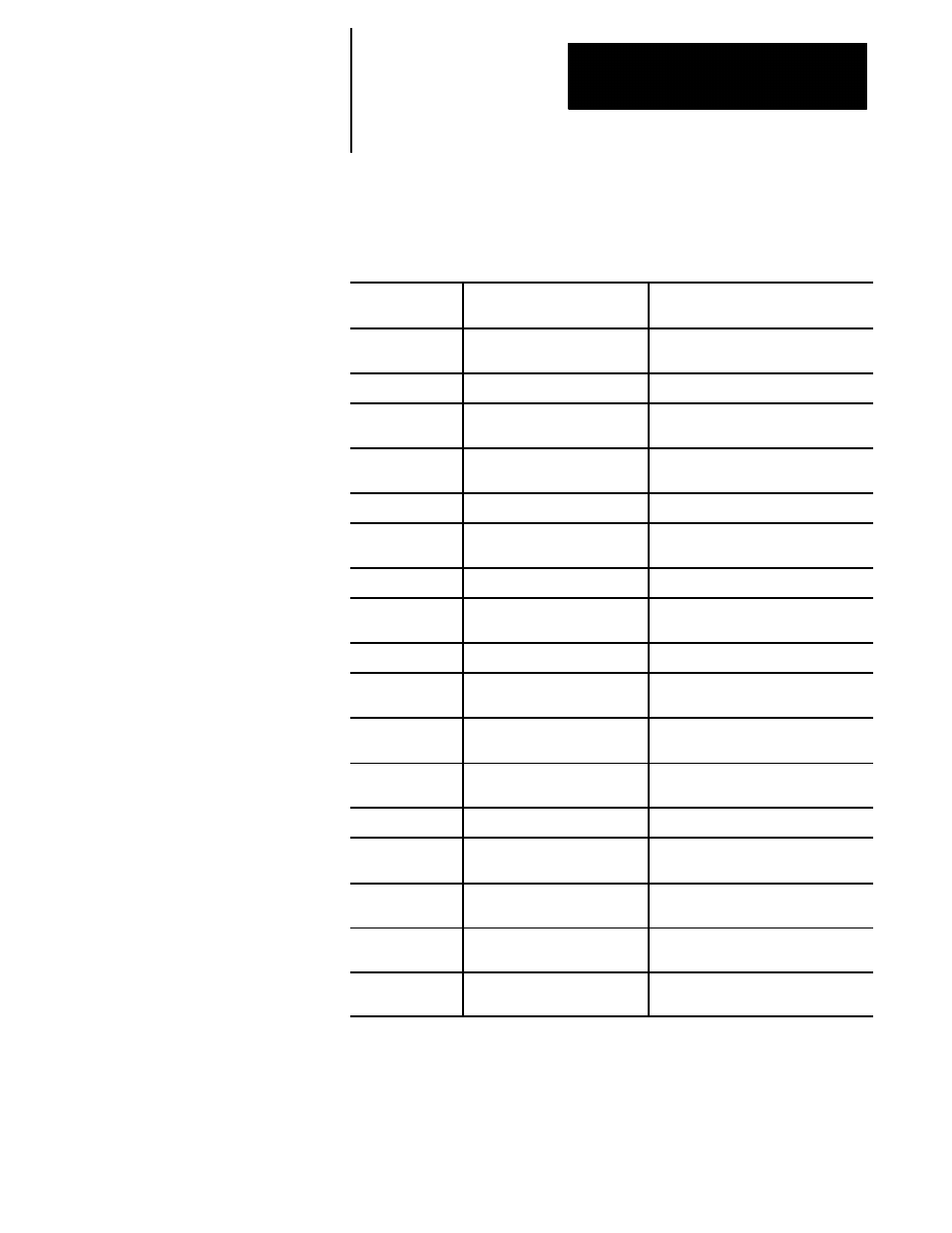

With the QuickView functions and QuickPath Plus, you can use

dimensions from part drawings directly to create a part program. The

sample patterns available with the QuickPath Plus prompts are summarized

below.

Use this pattern:

When you are programming

this geometry:

And you know the:

{CIR

ANG PT}

an arc to a line

arc radius and the taper angle of a line

{CIR CIR}

an arc to another arc

coordinates of the arc centers

{ANG

CIR PT}

a line to an arc

taper angle of a line and the arc radius

{1ANG PT}

a line

taper angle and either of the end point

coordinate values

{2ANG 1PT}

two successive lines

angles of two tapered lines

{2ANG

1PT R}

two lines joined by an arc

angles of two tapered lines

{2PT R}

two lines joined by an arc

intersection point of two lines

{2ANG

1PT C}

two lines joined by a chamfer

angles of two tapered lines

{2PT C}

two lines joined by a chamfer

intersection point of two lines

{2ANG

2PT R}

three lines joined by and tangent

to two arcs

taper angles of two lines and two arc

radii

{3PT R}

three lines joined by an arc

between two adjacent lines

two intersection points

{2ANG

2PT C}

three lines joined by chamfers

taper angles of two lines and one

intersection point

{3PT C}

three lines joined by chamfers

two intersection points

{2ANG

2PT RC}

three lines joined by an arc and a

chamfer

taper angles of two tapered lines and

one intersection point

{3PT RC}

three lines joined by an arc and a

chamfer

two intersection points

{2ANG

2PT CR}

three lines joined by an arc and a

chamfer

taper angles of two lines and one

intersection point

{3PT CR}

three lines joined by an arc and a

chamfer

two intersection points

5.3.1

Using {QPATH+ PROMPT}

Sample Patterns