Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 345

Chapter 11

Coordinate Control

11-29

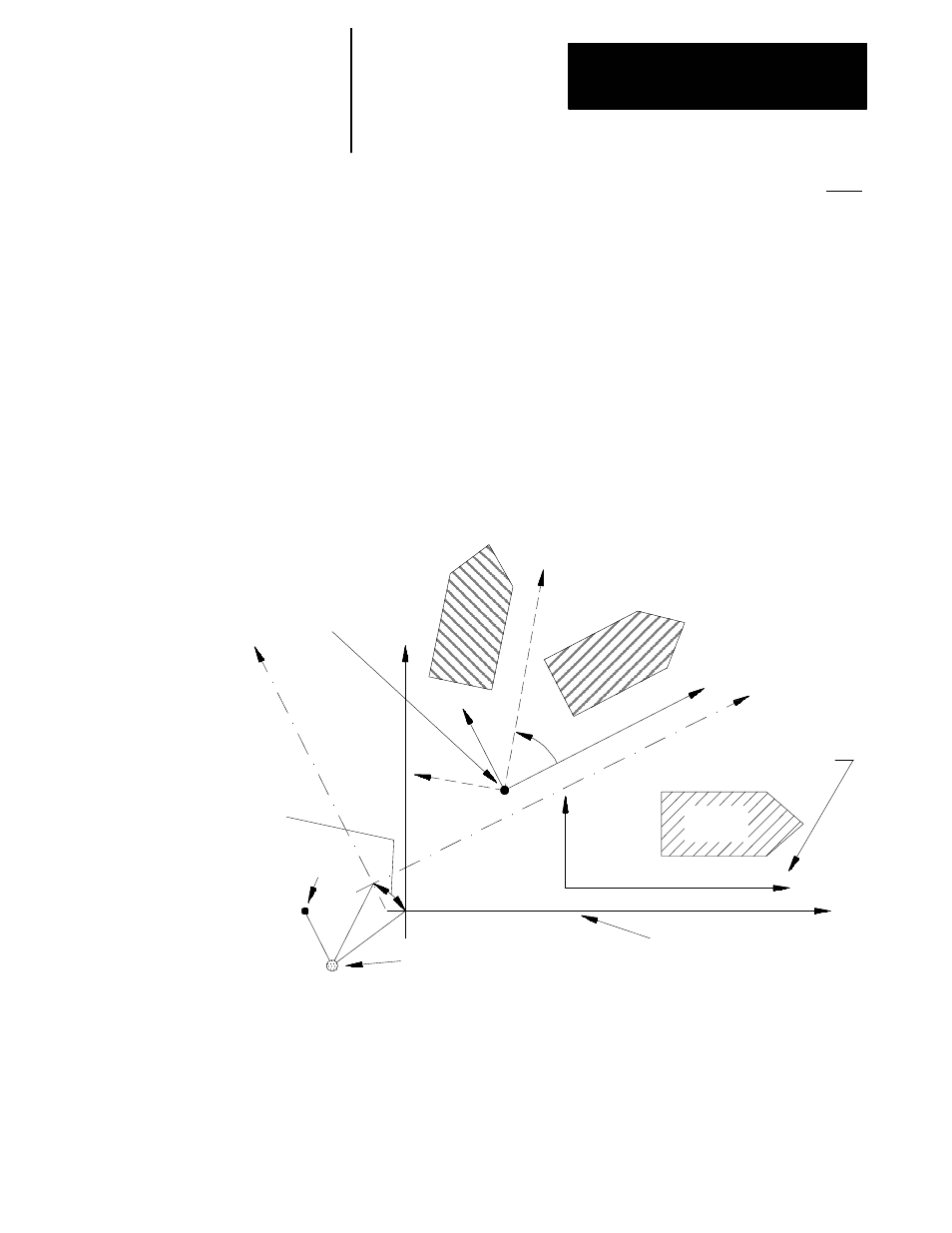

External Part Rotation can be executed before or after rotation of the work

coordinate system using the G68 command, see page 11-24. If a G68 is

programmed to rotate the current work coordinate system, an additional

rotation of coordinates result as shown in Figure 11.18.

Any work coordinate system rotation that is to be done using the external

rotation feature must be performed before program execution begins.

Program execution may not be interrupted to perform an external part

rotation. If you want to interrupt a program to perform an external part

rotation, the rotation does not become effective until the end of program

(M02 or M30) command is read, a control reset, or E-STOP reset is

performed.

Figure 11.18

External Part Rotation Followed by G68 Work Coordinate Rotation

Machine coordinate system

CENTER for External Part Rotation

Before

rotation

After External

rotation

Rotation center

for G68 Part Rotation

ANGLE for External

Part Rotation

VECTOR coordinates for

External Part Rotation

Work

coordinate

system

After External

and G68

rotation

12020-I

Important: This feature only simulates rotation of the machine coordinate

system for the purpose of establishing the preset work coordinate systems.

Software overtravels, programmable zones, and any other positioning

referenced on the machine coordinate system remain unaffected by this

rotation, but a program originally written within the limits can now be

outside these limits.