Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 504

Dresser/Wheel Radius Compensation

Chapter 15

15-16

You can program the generated block between the two dresser/wheel paths

as linear or circular with these G-codes:

G39(or G39.1);

Where :

Causes:

G39

linear transition blocks. If you program a G39 or G39.1, G39 is the

default (established at control reset or end of program command).

This command is modal.

G39.1

circular transition blocks. When programming straight line-to-arc or

arc-to-straight line moves, the generated block is always linear, and

the control ignores the G39.1. This command is modal.

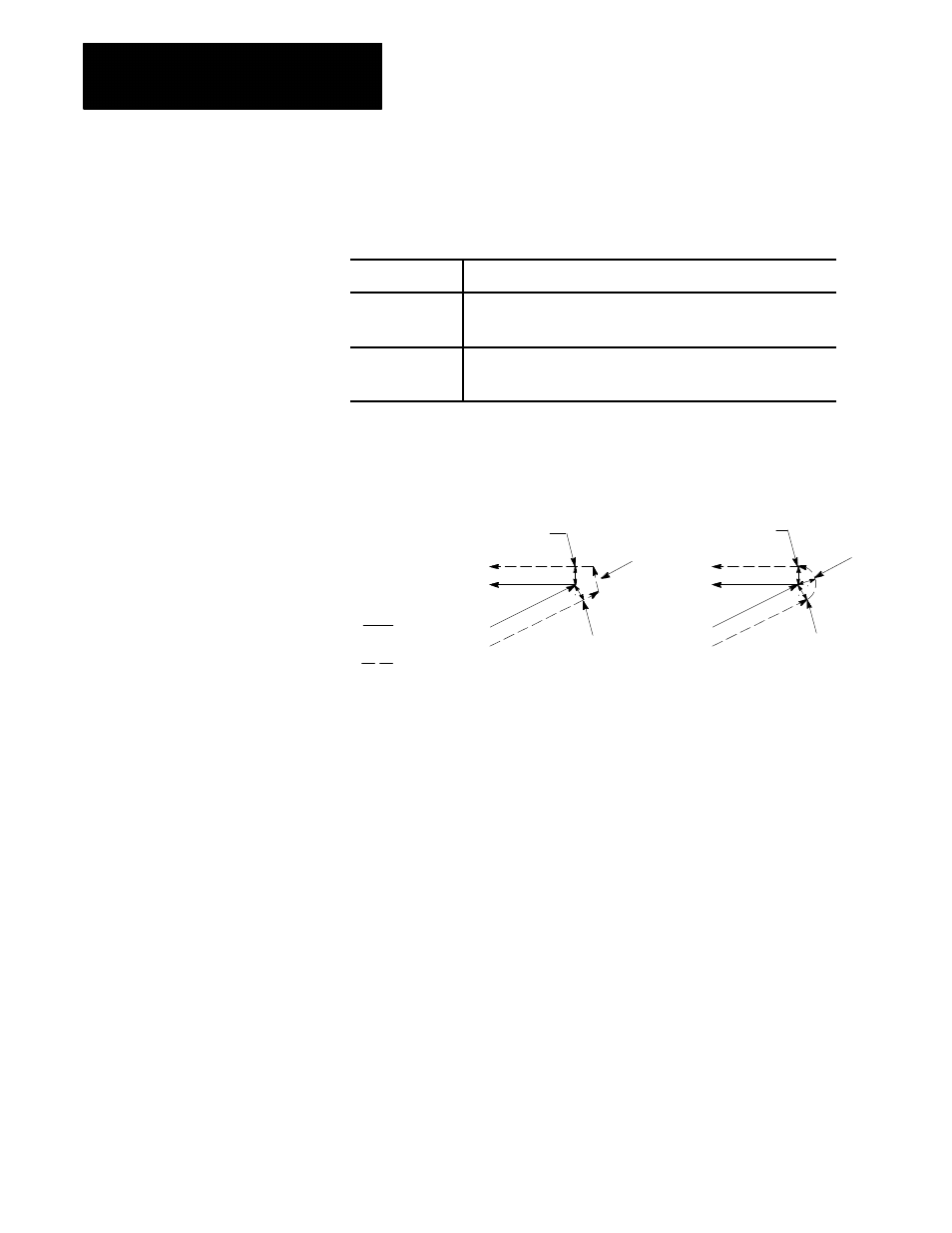

Figure 15.13

Dresser/Wheel Radius Compensation Generated Blocks (G39 vs G39.1)

G39 (Linear generated block)

End of

1st cut

Start of

2nd cut

r

r

r

block

generated

1st cut

Start of

2nd cut

G39.1 (Circular generated block)

r

r

r

Linear

block

generated

Circular

r

Programmed

path

G42 Tool path

Tool radius

r =

End of

12106-I

You can program a G39 or G39.1 in any block. However, you must

program them in or before the block that causes a dresser/wheel radius

compensation generated block.

Important: For linear generated blocks only, your system installer can

define a minimum block length in AMP. If the generated move length is

less than the system-defined minimum block length, no generated block is

created and the dresser/wheel path proceeds to the intersection of the two

compensated paths. If the generated move length is equal to or greater

than the system-defined minimum block length, a generated block is

created.

Throughout this chapter, we show drawings where a generated block is

created. Both G39 and G39.1 are shown in these drawings where

applicable.