1 surface grinding considerations, Modality and programming – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 552

Surface Grinding Fixed Cycles

Chapter 16

16-2

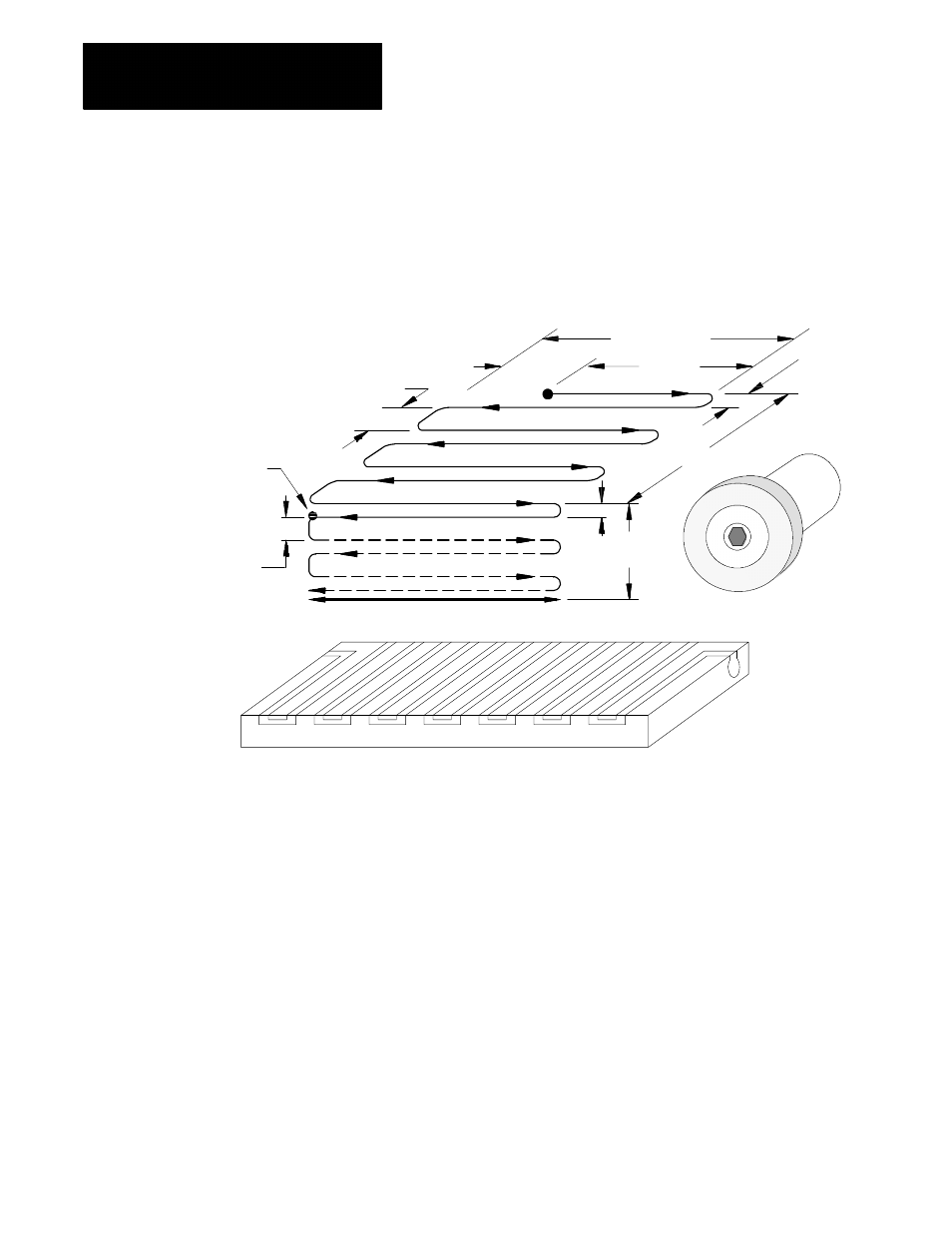

Figure 16.2 illustrates the reciprocation, plunge, and crossover motions of

a typical surface grinding cycle (G83 Incremental Plane grinding in this

case) .

Figure 16.2

Reciprocation, Crossover, and Plunge Motions

Crossover

Plunge

pick

at

secondary reversal

(executed after the

crossover

axis

returns

to

its

secondary reversal

coordinate)

Plunge

Plunge

pick at

primary

reversal

Spark--out passes

Cross

pick

at

secondary reversal

Reciprocation

Sec.

rev.

Primary

reversal

Cross pick a

primary

reversal

START

Magnetic table

At this point, the

crossover moves are

executed in reverse

until the crossover

axis is at its start

coordinate

12046-I

Modality and Programming

These surface grinding cycles are modal. Once programmed, the cycle is

executed in each subsequent block that contains the appropriate parameters

and parameter values. The G codes corresponding to these cycles do not

have to be programmed in each block.

Typically crossover and plunge axis motions are coordinated with the

motion of a reciprocating axis.

You can access Grinder Prompts through the Quick-view screens

(described in chapter 5) to simplify programming.

16.1

Surface Grinding

Considerations